High-precision device for measuring rolling moment based on mechanical bearing support

A technology for bearing support and torque measurement, which is applied in the direction of measuring devices, machine/structural component testing, aerodynamic testing, etc., can solve the problems of high test cost and long test time, and achieve reduced interference, low development cost, and good performance. Rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further introduced below in conjunction with the accompanying drawings.

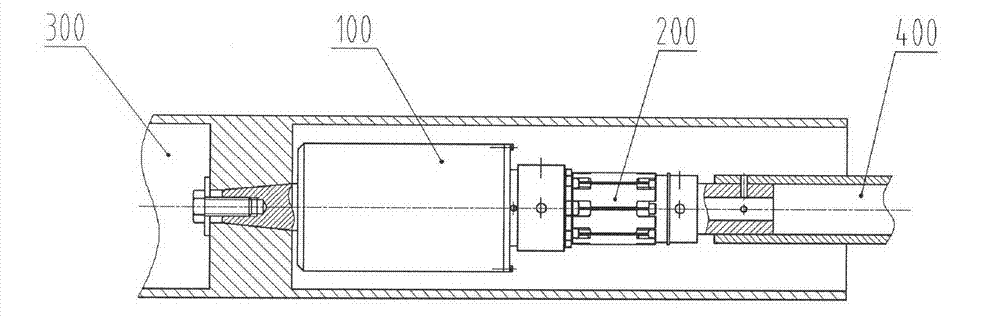

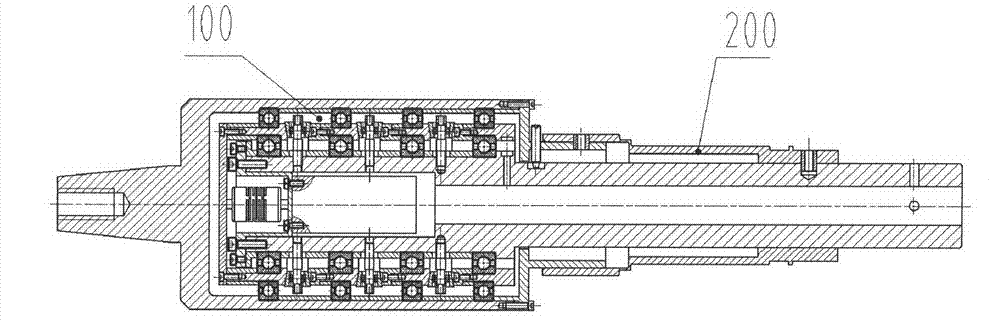

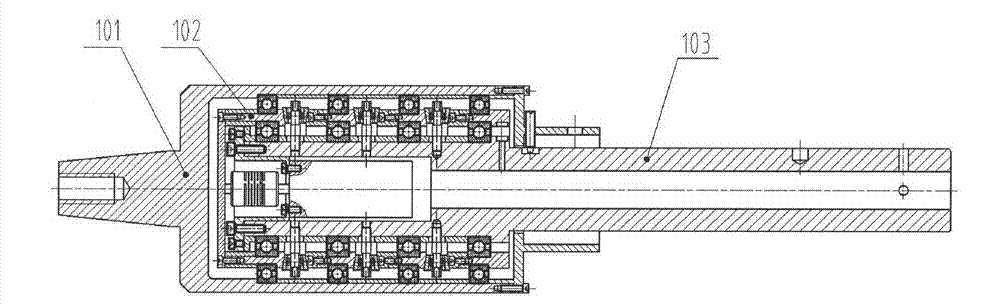

[0027] Such as figure 1 As shown, the high-precision rolling moment measurement device based on the mechanical bearing support of the present invention includes a mechanical bearing support 100 and a single-component rolling moment balance 200 . During the test, the front end of the housing assembly 101 of the mechanical bearing support 100 is fixed to the measured wind tunnel model 300 . The rear end of the central axis assembly 103 of the mechanical bearing support 100 is fixed to the model strut 400, and the device and the measured wind tunnel model 300 are fixed together in the wind tunnel. Among them, the mechanical bearing support 100 is used to bear all radial loads and axial loads, and overcome the influence of these loads on the rolling moment measurement. The single-component rolling moment balance 200 is used to measure the rolling moment, and has suffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com