Gripping device for milking unit

A device and holding technology, applied in milking devices, animal houses, dairy products, etc., can solve problems such as time-consuming, difficult operation, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

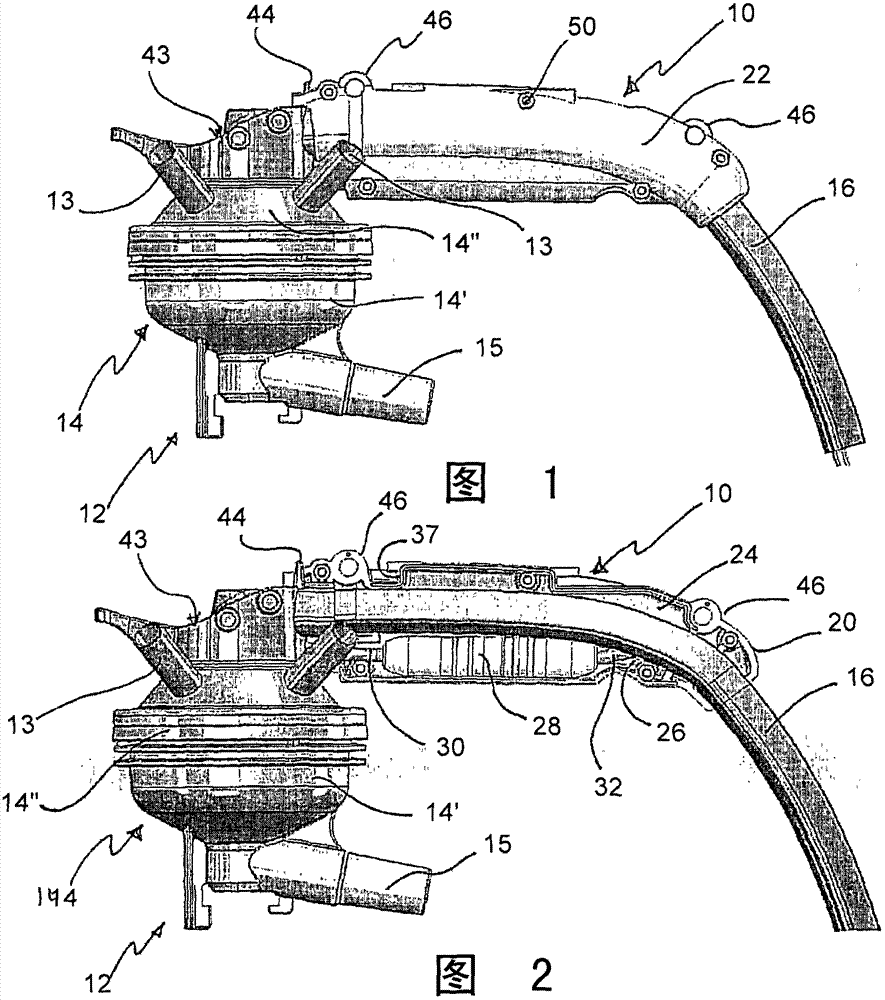

[0024] With reference to the preceding figures, by way of non-limiting example, there is shown a holding device for a milking machine applied to a milking machine 12 of the conventional and known single parlor type, generally indicated with the reference numeral 10 , including: a milk collector 14, which is equipped with an output pipe 15 arranged on the bottom 14' of the milk collector, and needs to be provided with a pipeline connection for collecting the expressed raw milk flowing in the milk collector; 2 or 4 pipes 13 extend in the direction opposite to the output pipe 15 on the top 14" of the milk collector, and have 2 or 4 bosses on which milk cups (not shown) are installed; connected to the milk collector Pulse tube 16 on device 14.

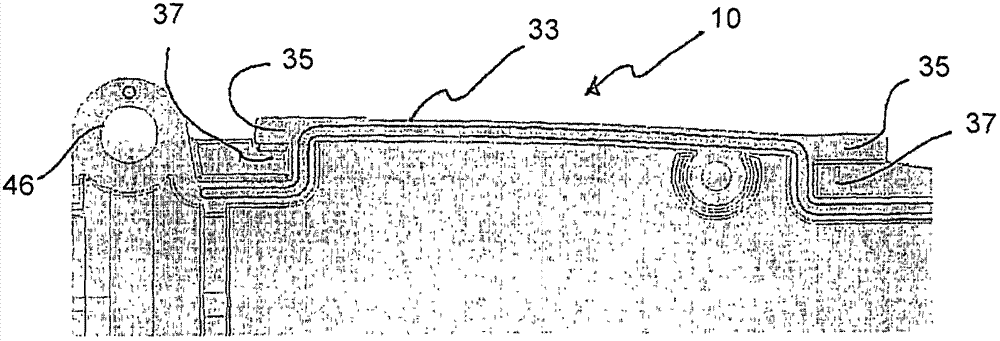

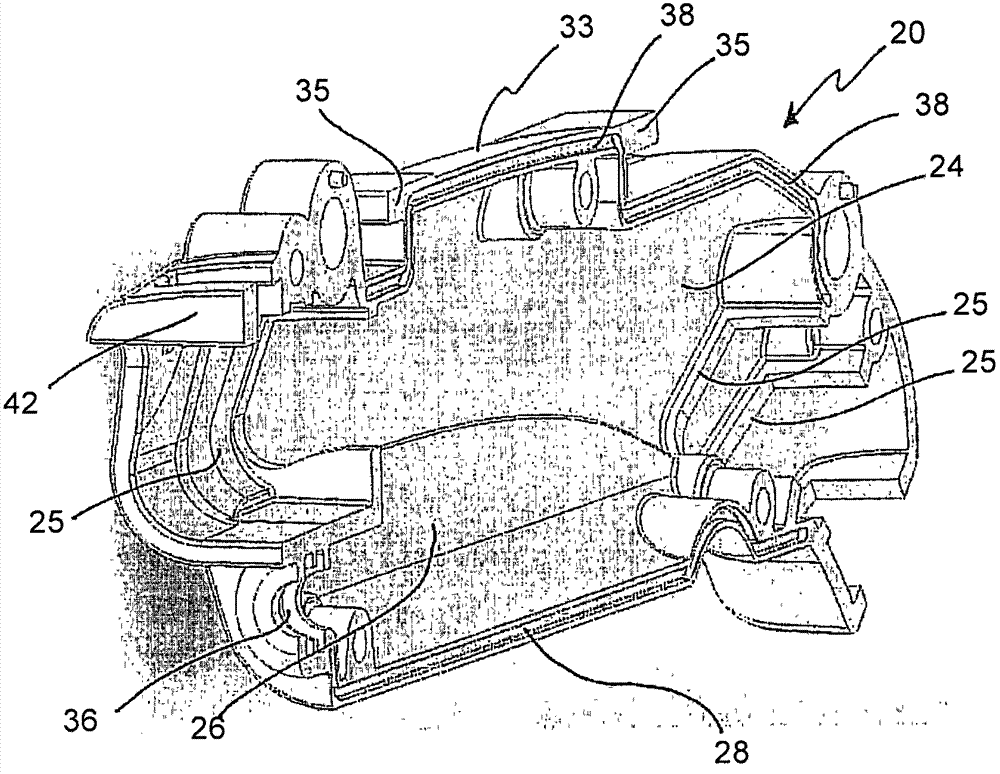

[0025] The holding device 10 preferably but not exclusively comprises two half-shells 20 and 22 made of plastic or other suitable material, each formed from a single shell or from two or more components Formed to cooperate with each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com