Wrapped target spraying device

A spray device and wrap-around technology, which is applied in the field of wrap-type target spray devices, can solve the problems of poor droplet penetration performance, improve the effective deposition rate, alleviate environmental and food safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

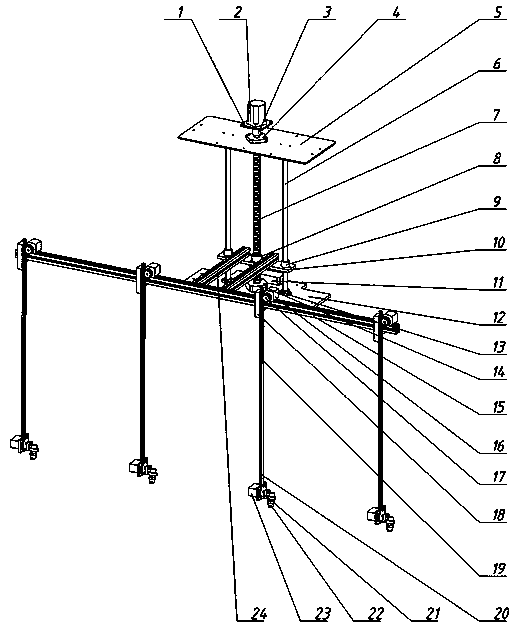

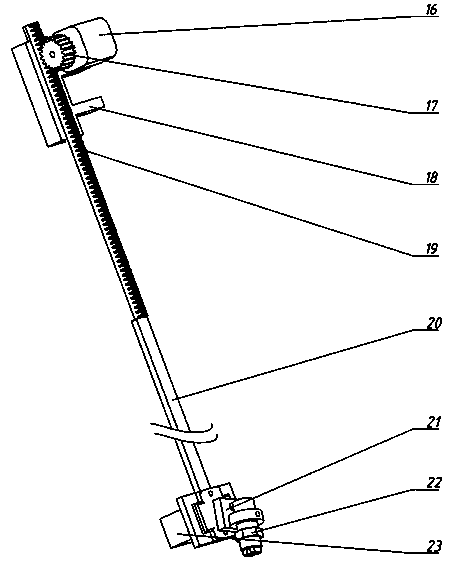

[0020] like figure 1 , figure 2 Shown, the present invention comprises lead screw lifting platform, targeting mechanism and DSP controller; Wherein:

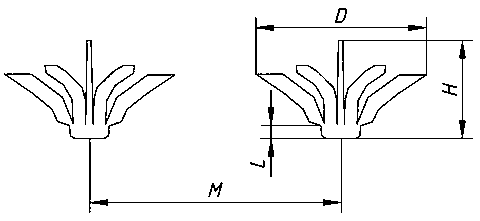

[0021] 1) Screw lifting platform: including motor support plate 1, first stepping motor 2, coupling 3, upper fixed screw support seat 4, upper support plate 5, guide shaft 6, ball screw 7, screw bearing 8. Linear bearing 9, connection plate 10, lower support plate 12, support seat 13, lower fixed screw support seat 14, spray rack 15 and two connecting rods 24. The upper support plate 5 is connected with the upper fixed screw support seat 4 by bolts, the motor support plate 1 fixedly supports the first stepping motor 2, one end of the coupling 3 is connected to the first stepping motor 2, and the other end of the coupling 3 is connected to the ball screw One end of the rod 7 is connected, and after the ball screw 7 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com