A magnetically permeable coating with dense structure and its preparation method

A coating and magnetic conductivity technology, applied in the direction of magnetic objects, magnetic materials, electric/magnetic/electromagnetic heating, etc., can solve the problems of decreased electromagnetic heating eddy current effect, decreased block compactness, decreased heating power, etc., to improve the conductivity. Magnetic coating bonding force and electromagnetic heating power, not easy to fall off, strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

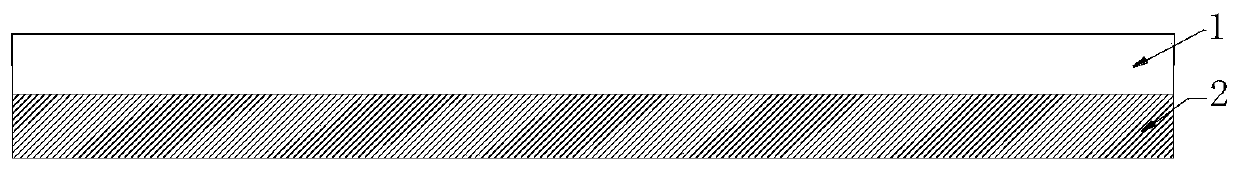

[0053] The invention also discloses a method for preparing a magnetic conductive coating with a dense structure, which comprises the following steps: cold spraying the magnetic conductive metal powder on the surface of the structure to be sprayed by using a working gas.

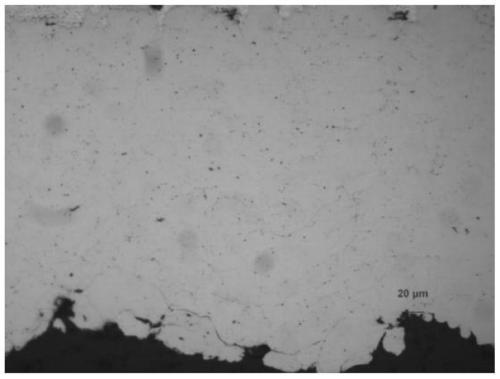

[0054] The working gas is one or more of air, helium and nitrogen. The spray pressure of the cold spray is 1-3.5Mpa. The spray temperature of the cold spray is 573-1273K. The gas velocity of the cold spraying is 1~2.4m 3 / min. The conveying speed of the cold sprayed magnetic conductive powder is 5-15kg / h. The spray distance of the cold spray is 10-50 mm. The power consumption of the cold spraying is 15-55kW. The magnetically permeable metal is selected from Fe, Ni, Co, Fe-Si, stainless steel, or a mixture of several. The powder particle size of the magnetically conductive metal is 1-50 μm. The thickness of the magnetic conductive coating is 0.1-0.6 mm.

[0055] Further, the above process conditions ma...

Embodiment 1

[0063] A pot body includes a pot body and a magnetic conductive coating, the magnetic conductive coating is located on the outer surface of the pot body. The material of the pot body is aluminum alloy.

[0064] The magnetic conductive coating is prepared on the pot body by the cold spraying process, which includes the following steps:

[0065] 1. Degreasing and degreasing the outer surface of the pot body to be sprayed;

[0066] 2. Cold spray the magnetically conductive metal powder on the outer surface of the pot body through the working gas, and the magnetically conductive metal powder forms a magnetically conductive coating on the surface of the pot body. The specific process parameters are:

[0067] (1) The magnetic conductive powder is selected from Fe powder with a purity of 99.0-99.8%, and the powder particle size is 10-20 μm; the working gas is high-purity nitrogen, the purity of nitrogen is 99.99%, and the spraying distance is 25-30mm; spraying temperature ( That is...

Embodiment 2

[0070] A pot body includes a pot body and a magnetic conductive coating, the magnetic conductive coating is located on the outer surface of the pot body. The material of the pot body is 304 stainless steel.

[0071] The magnetic conductive coating is prepared on the pot body by the cold spraying process, which includes the following steps:

[0072] 1. Use a masking jig to cover the position where the outer surface of the pot body to be sprayed does not need to be sprayed;

[0073] 2. Cold-spray the magnetically conductive metal powder on the surface of the pot body through the working gas, and the magnetically conductive metal powder forms a magnetically conductive coating on the surface of the pot body. The specific process parameters are:

[0074] (1) The magnetic conductive powder is selected from Fe powder with a purity of 99.0-99.8%, and the powder particle size is 10-20 μm; the working gas is high-purity nitrogen, the purity of nitrogen is 99.99%, and the spraying dista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com