Patents

Literature

48results about How to "Warm up well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application for solid beverage

ActiveCN103859547AAvoid volatile lossExtract maximumNatural extract food ingredientsFood ingredient functionsBiotechnologyMedicinal herbs

The invention discloses a preparation method and application for solid beverage. The solid beverage is prepared from the following raw materials in parts by weight: 2-6 parts of fresh gingers, 2-6 parts of jujubes, 1-2 parts of yams, 0.1-1 part of pericarpium citri reticulatae, 0.1-1 part of dried gingers, 0.5-2 parts of red sugar, 0.2-0.5 part of liquorice, 2-6 parts of fructose, 0.3-1 part of maltodextrin and 0.3-1 part of beta-cyclodextrin. The preparation method comprises the steps of fresh ginger juicing, supercritical dried ginger CO2 extraction, extraction concentration, spraying drying, granulation and the like. According to the preparation method, the volatilization loss of volatile oil under long-time heating extraction is avoided, effective components in the medicinal materials are extracted to the maximum extent, and the effects are guaranteed; the fresh ginger juice is subjected to spraying drying after being covered with the beta-cyclodextrin and the maltodextrin, so that the original fragrance of the ginger is kept to the maximum extent. The solid beverage product prepared by adopting the preparation method tastes good, is prepared from heat water, is convenient to prepare, drink and carry and is an ideal medicinal-edible dual-purpose beverage; tests show that extremely good effects of preventing the coldness, warming the body, tonifying spleen, warming stomach, preventing fever and dysmenorrhea and the like are achieved when people take the product for long time.

Owner:GUANGDONG YIFANG PHARMA

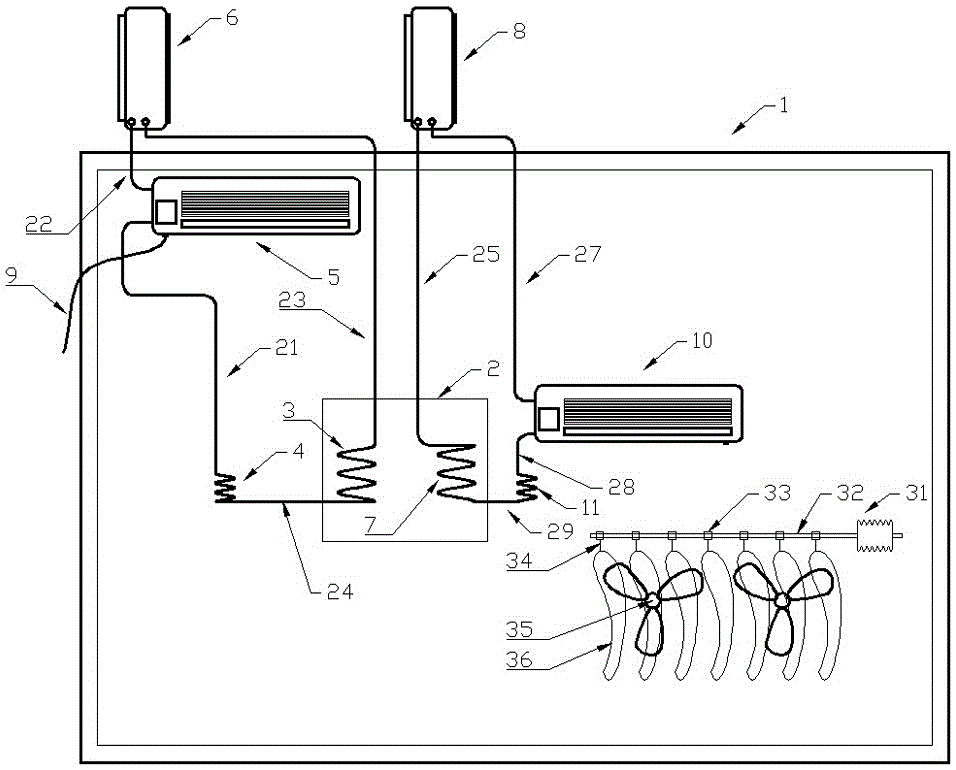

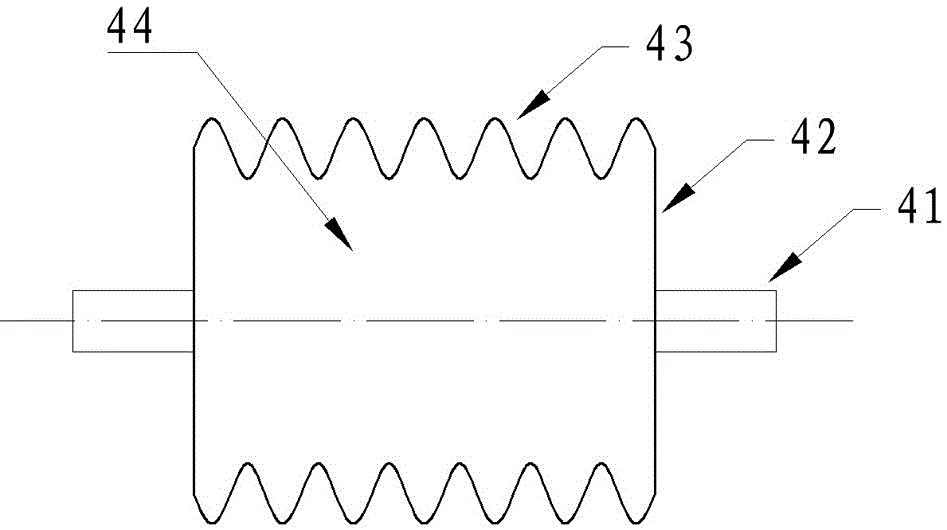

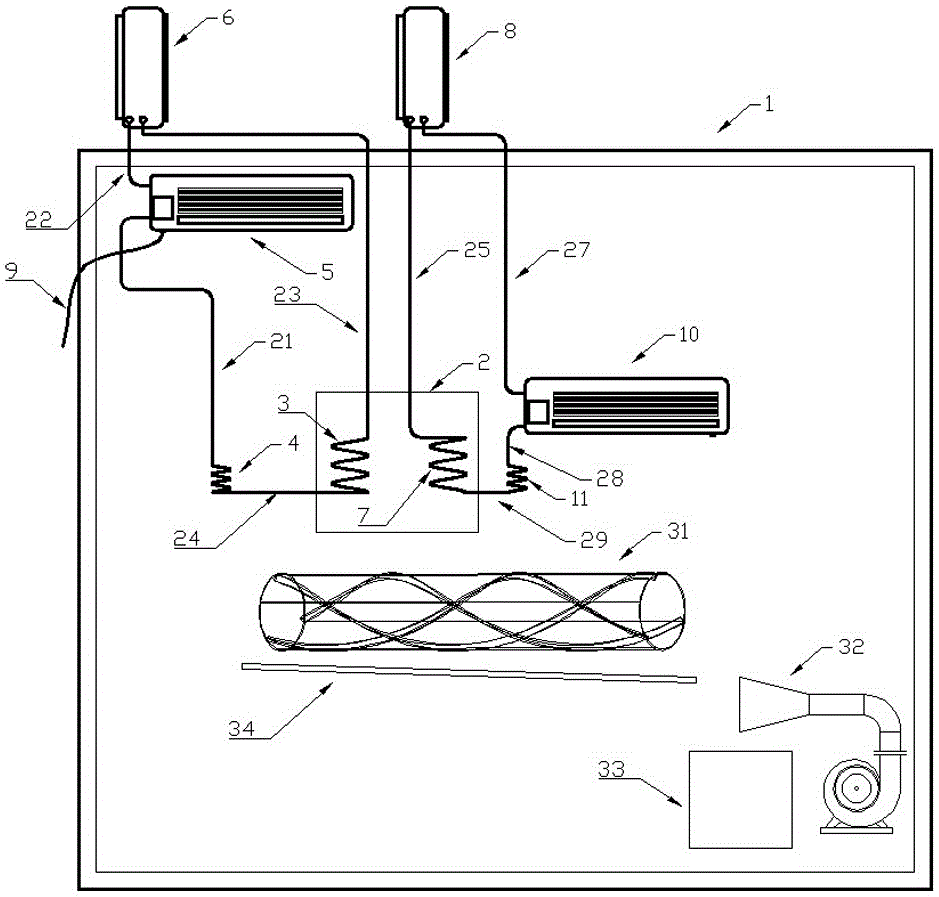

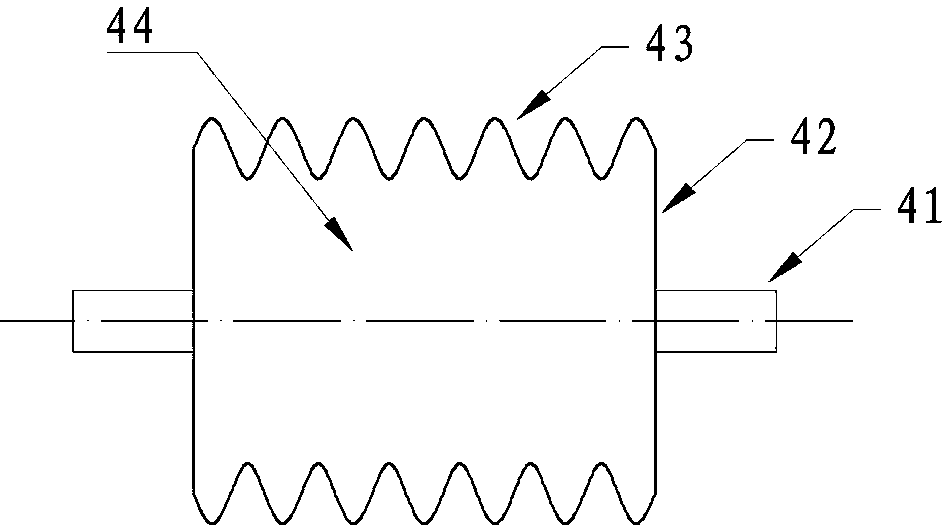

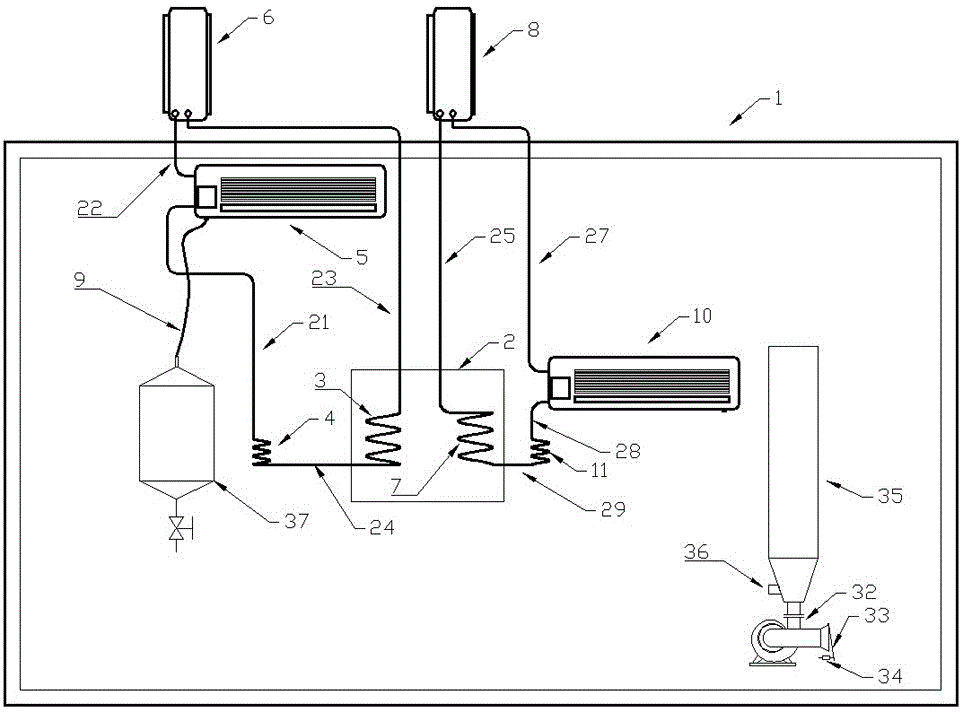

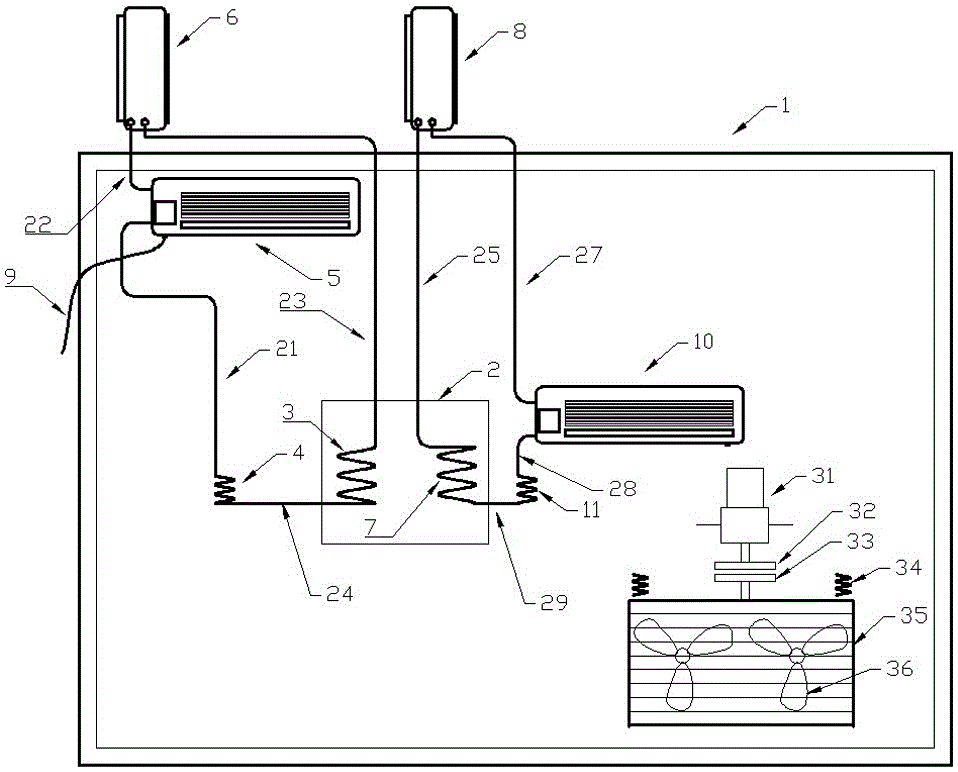

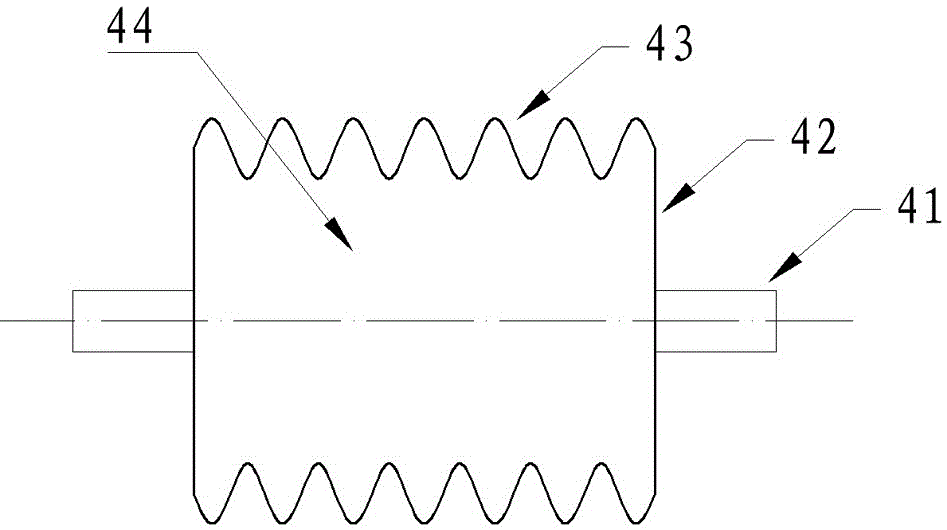

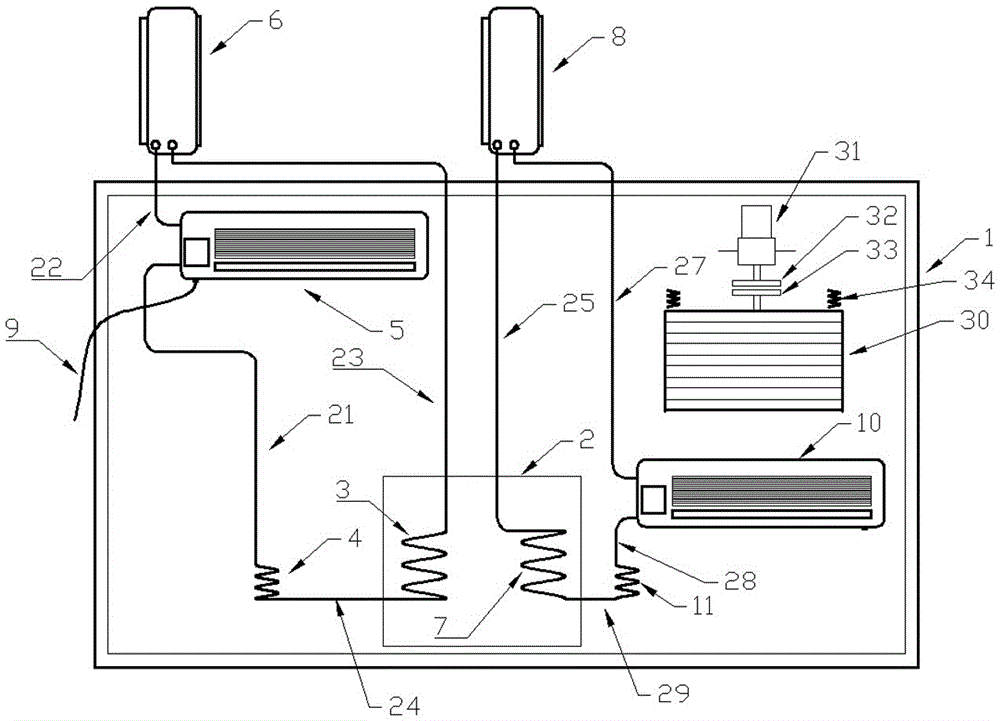

Preserved meat drying device driven to rotate by sine wave thermal expansion

InactiveCN106052367AReduce lossZero emissionFood processingHeating arrangementThermal expansionEngineering

The invention discloses a preserved meat drying device driven to rotate by sine wave thermal expansion. A water tank is arranged in a heat preservation fence; water is injected into the water tank to immerse a spiral pipe A and a spiral pipe B in the water tank; a compressor A, the spiral pipe A, a capillary pipe A, a refrigeration air conditioner indoor unit and a pipeline form a heat pump circulation dehumidification system A; a heating air conditioner outdoor unit, a heating air conditioner indoor unit, a capillary pipe B, the spiral pipe B and a pipeline form a heat pump circulation dehumidification system B; the system A and the system B alternately work to evaporate, condense and discharge water in the preserved meat in the heat preservation fence, store and use the heat in the water tank; sine wave expander connection racks are arranged inside the heat preservation fence; small gears meshed with the racks are connected to the preserved meat through hooks; convection fans are arranged near the preserved meat. Compared with the existing gaseous dehumidifying and drying manner, the energy consumption is greatly reduced; the zero emission of refrigeration and dehumidification heat can be achieved; meanwhile, the thermal expander is capable of enabling the preserved meat to generate corner change along the temperature change, preventing the preserved meat from being hardened and accelerating drying and dehydration.

Owner:JISHOU UNIVERSITY

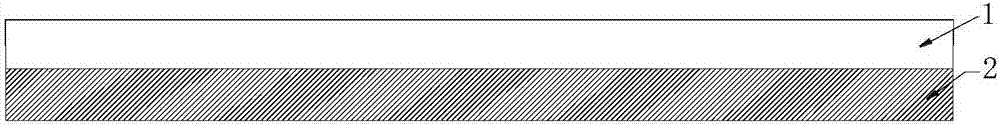

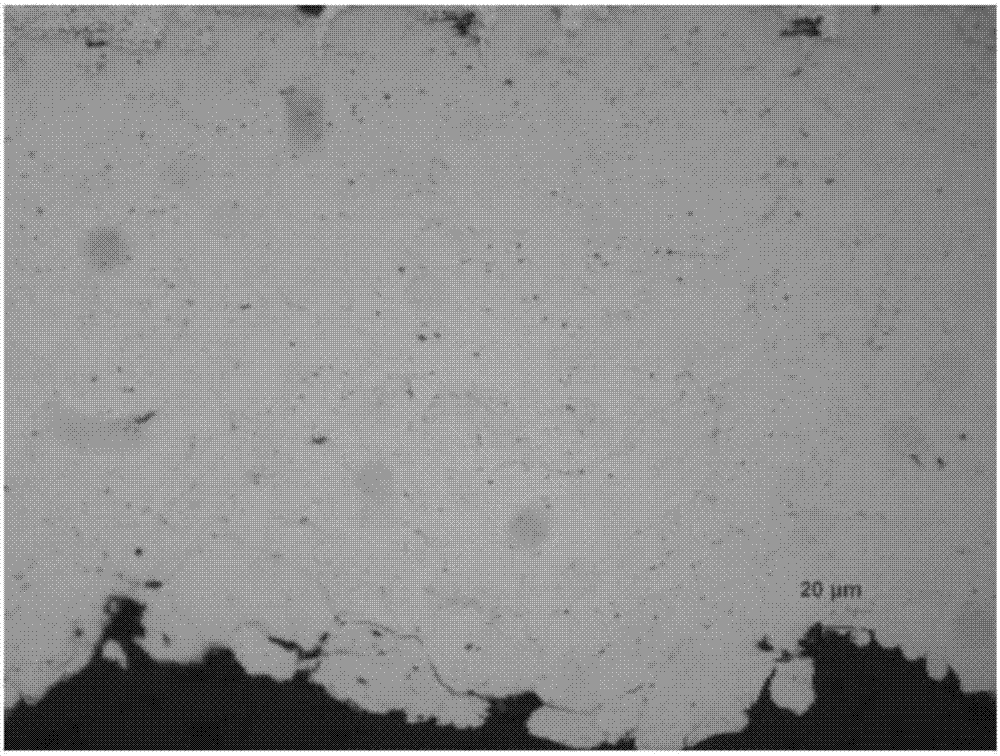

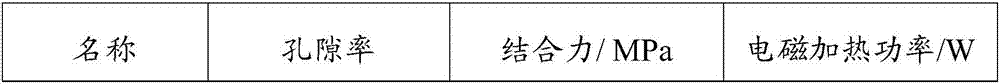

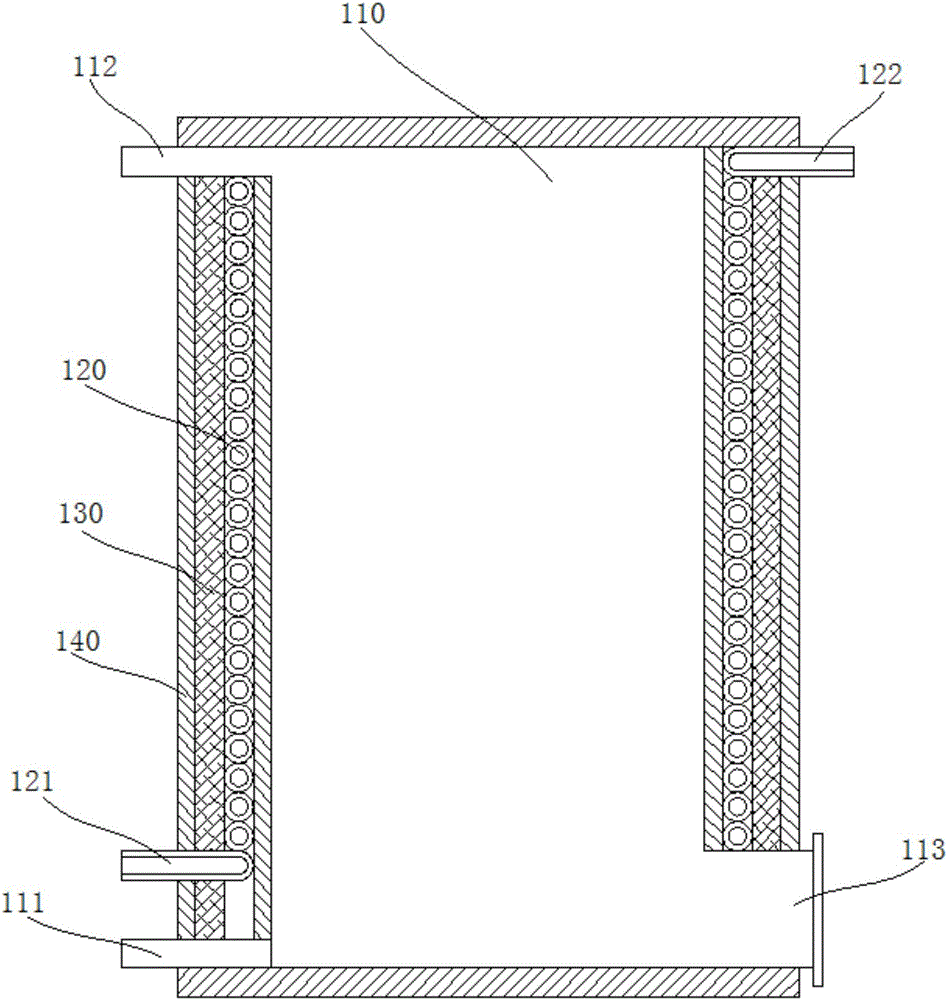

Magnetic conducting coating with compact structure and preparation method thereof

ActiveCN107090578AImprove bindingNot easy to fall offCooking-vessel materialsRefuse receptaclesBinding forcePorosity

The invention relates to a magnetic conducting coating with a compact structure and a preparation method thereof. The magnetic conducting coating with the compact structure is applied on the surface of a base material as a layered coating, the magnetic conducting coating is prepared through a cold spray process, and the porosity of the magnetic conducting coating ranges from 0.05% to 0.25%. The magnetic conducting coating has the characteristics of being high in compactness, strong in binding force and not easy to fall off, the porosity ranges from 0.05% to 0.25%, and the magnetic conducting coating has the beneficial effect of improving the binding force of the magnetic conducting coating and the electromagnetic heating power; if the porosity is lower than the range, the technological process is difficult to implement; and if the porosity is higher than the range, the bonding force of the magnetic conducting coating and the electromagnetic heating power are reduced. The invention further relates to the preparation method of the magnetic conducting coating with the compact structure, and relates to a pot body and a cooking utensil containing the magnetic conducting coating.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

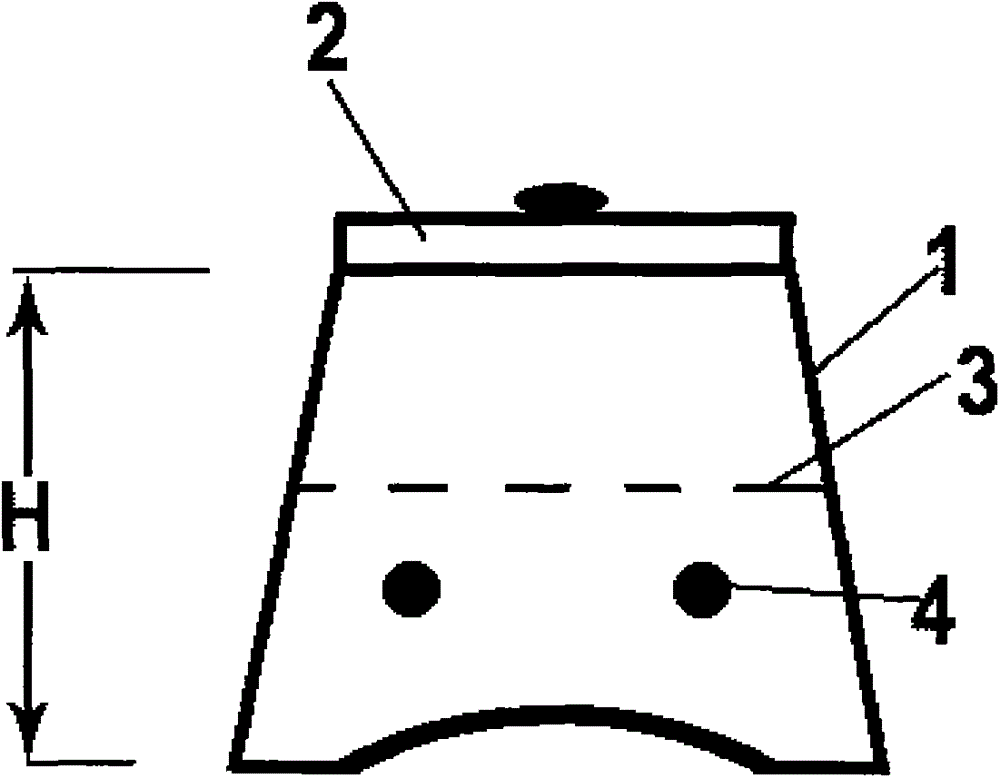

Constant-temperature moxibustion box capable of quickly raising temperature

InactiveCN103445956AHeating up fastMaintain therapeutic temperatureDevices for heating/cooling reflex pointsEngineeringMoxibustion

The invention discloses a constant-temperature moxibustion box capable of quickly raising the temperature. The constant-temperature moxibustion box comprises a box body, a box cover and an ash filtering screen and is characterized in that the box cover is a sealing plate which is the same as the top of the box body in size and shape, and thus an opening on the top of the box body can be covered and sealed; two ventilation holes are formed in each wall board corresponding to a long side of the box body; the diameters of the ventilation holes are 1.5-2cm; the distance between the ash filtering screen and the bottom of the box body is 7-13cm; the height of the box body is 13-20cm. The constant-temperature moxibustion box disclosed by the invention has the advantages that the structure is simple, the convenience in operation is realized and quick temperature rise and long-time heat preservation can be realized.

Owner:葛理明

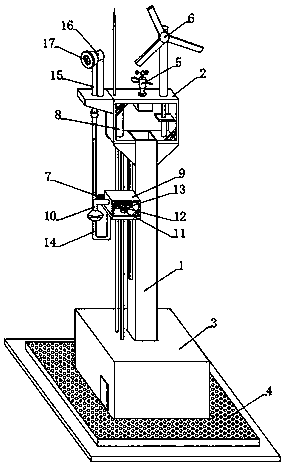

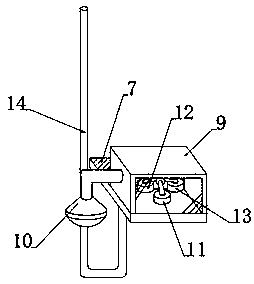

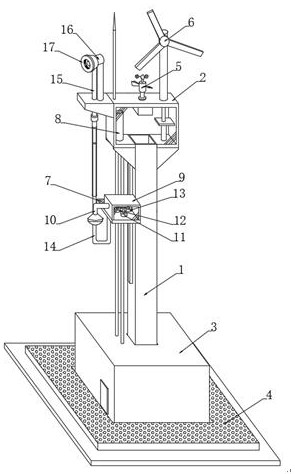

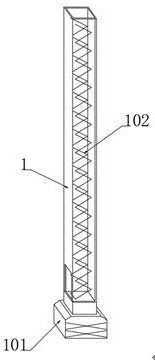

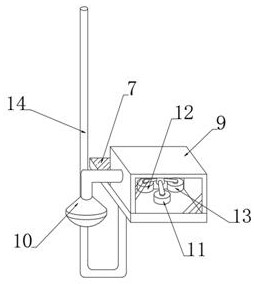

Fire prevention and monitoring device for mountainous areas

ActiveCN111337084APlay the role of fire isolationPlay a protective effectFouling preventionMeasurement apparatus componentsWind runTower

The invention discloses a fire prevention and monitoring device for mountainous areas and belongs to the technical field of fire prevention monitoring. The fire prevention and monitoring device comprises a monitoring tower and an operation room fixedly connected to the monitoring tower. A wind speed and direction sensor and a windmill are mounted on the operation room; a lifting plate is fixedly connected to the side wall of one side of the monitoring tower; a tower body protection mechanism consisting of a tower bottom fireproof cover and a fireproof isolation layer is arranged at the bottomend part of the monitoring tower; the tower bottom fireproof cover and the fireproof isolation layer have a certain fireproof isolation effect on the tower body. An exhaust pipe arranged on an environment monitoring box is communicated with a blast protective cover arranged on a thermal imaging camera and air guided out from the environment monitoring box is guided out from the inner wall of the blast protective cover and a flow guide pipe and a heating mechanism are used for cooperation, so that a lens end face of the thermal imaging camera is effectively cooled or an icing layer and frost onthe lens end face are effectively removed through gas, and thus the thermal imaging camera is protected to a certain extent.

Owner:天立泰科技股份有限公司

Constant-temperature moxibustion box capable of quickly raising temperature

InactiveCN103445956BHeating up fastMaintain therapeutic temperatureDevices for heating/cooling reflex pointsEngineeringMoxibustion

Owner:葛理明

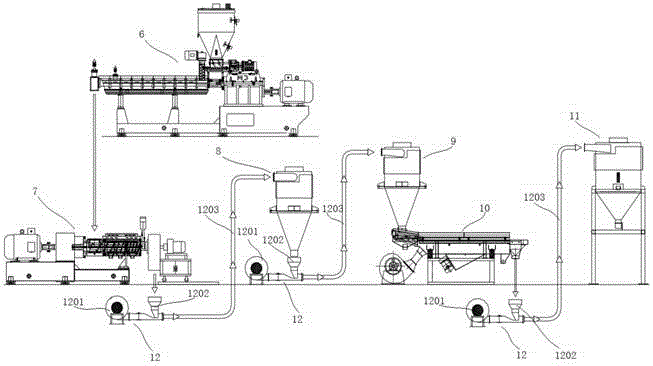

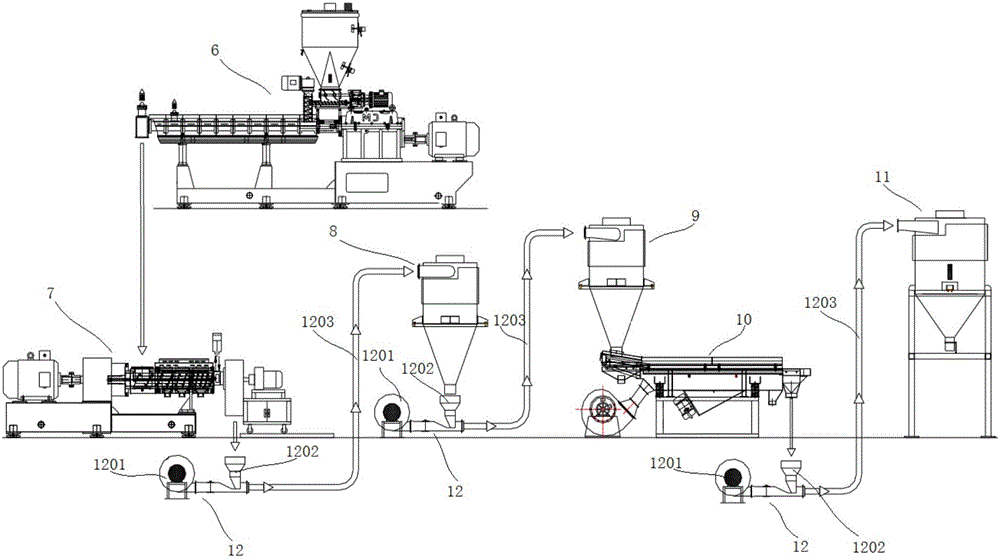

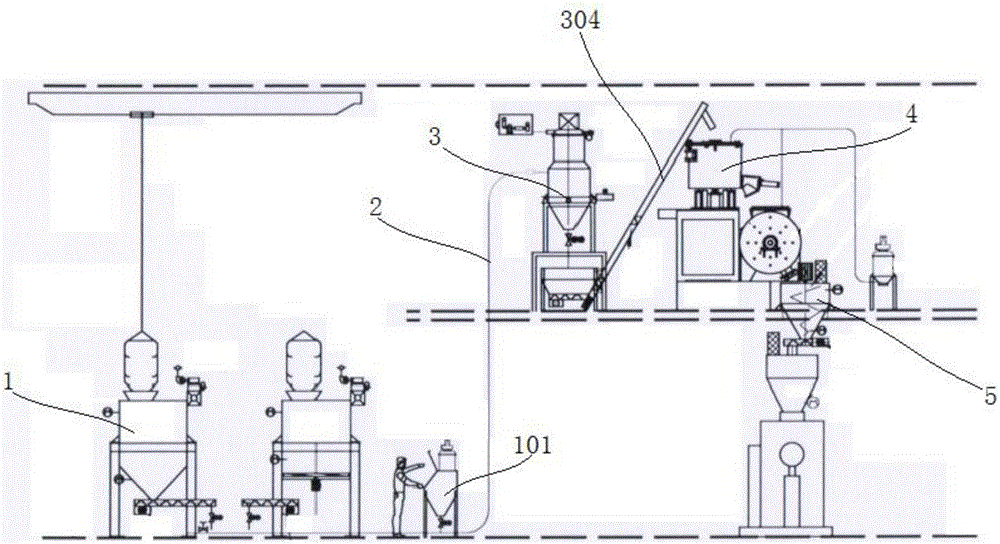

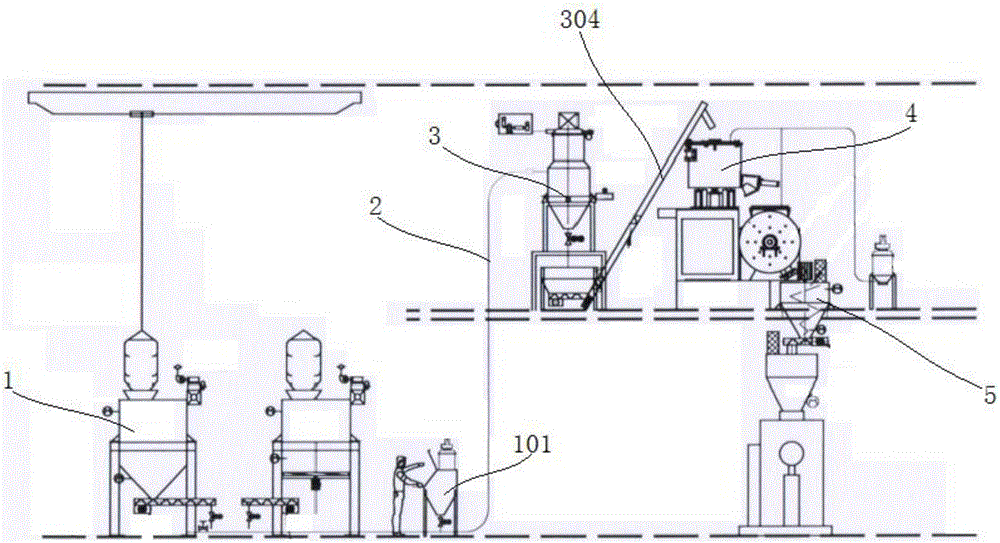

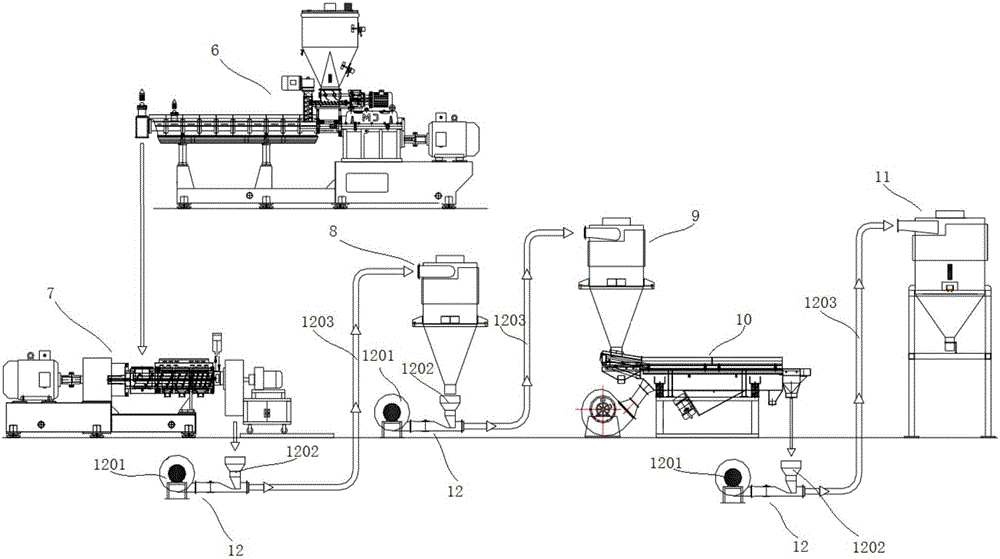

Low-noise plastic production device capable of achieving efficient feeding

The invention relates to the technical field of plastic processing equipment, in particular to a low-noise plastic production device capable of achieving efficient feeding. The low-noise plastic production device comprises a material bin, a material conveying pipe, a material weighing machine, a material mixing machine, a temporary material bin, an extruder, a die surface hot cutting pelletizer, a first cyclone separator, a second cyclone separator, a vibrating screen and a packing machine which are sequentially connected; the positions between the die surface hot cutting pelletizer and the first cyclone separator, between the first cyclone separator and the second cyclone separator and between the vibrating screen and the packing machine are each provided with an air conveying system; each air conveying system comprises a conveying draught fan, a connecting tee joint and a conveying pipe; the side face of the material bin is spirally wound with a water passing pipe, a heating runner and a feeding channel are constructed at the middle portion of the conveying pipe in the axial direction, and the positions of the conveying draught fans are covered with sound isolation covers; and the positions of the material mixing machine, the first cyclone separator and the second cyclone separator are each provided with a waste gas outlet, and all waste gas outlets are connected with a spraying tower. The low-noise plastic production device can be better applied to plastic processing technologies.

Owner:DEQING BAISHENG PLASTIC CO LTD

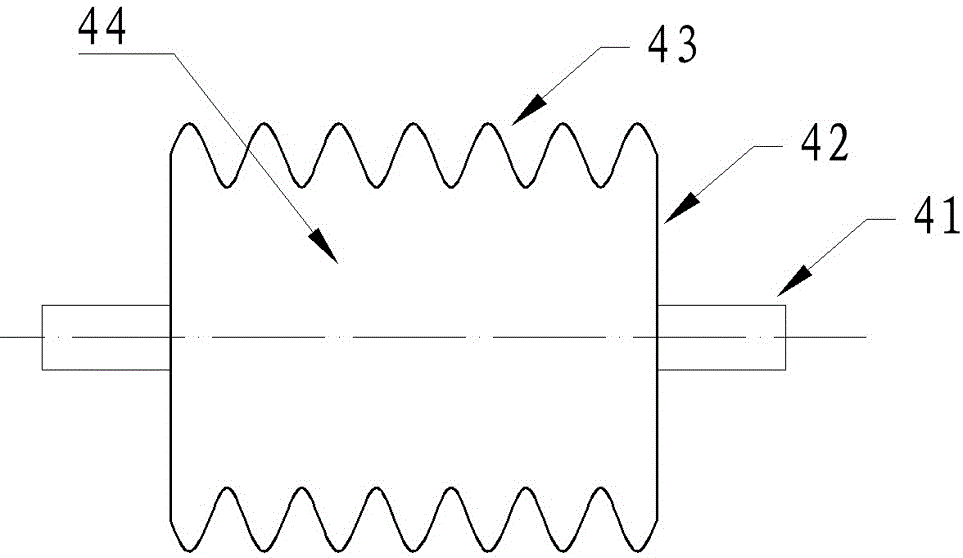

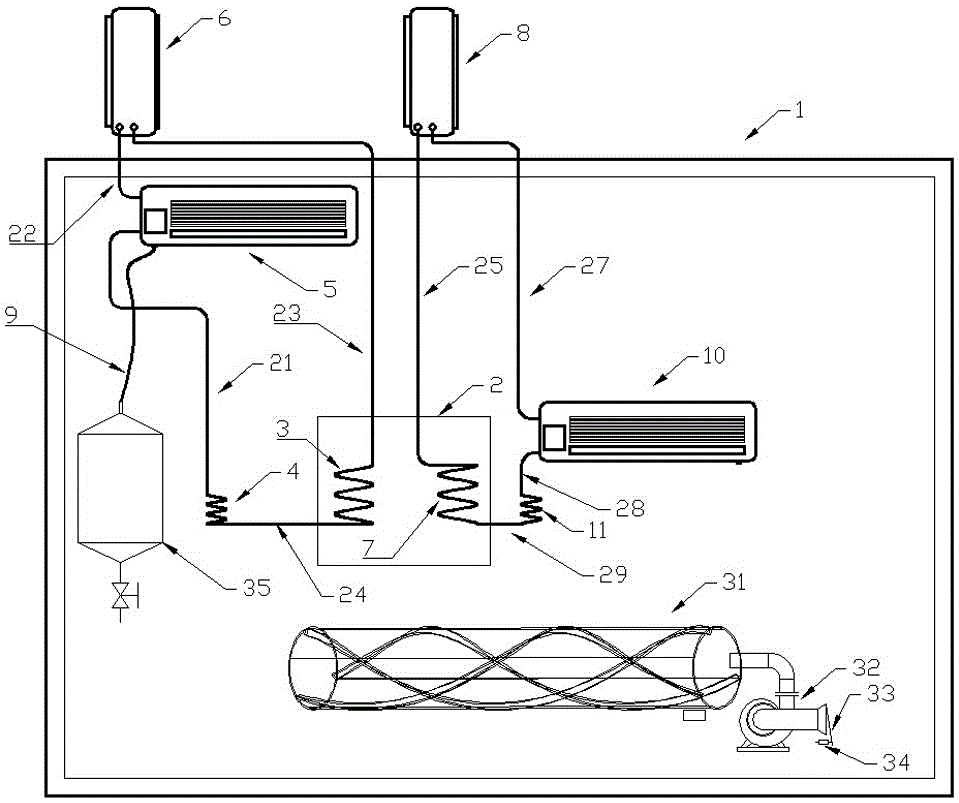

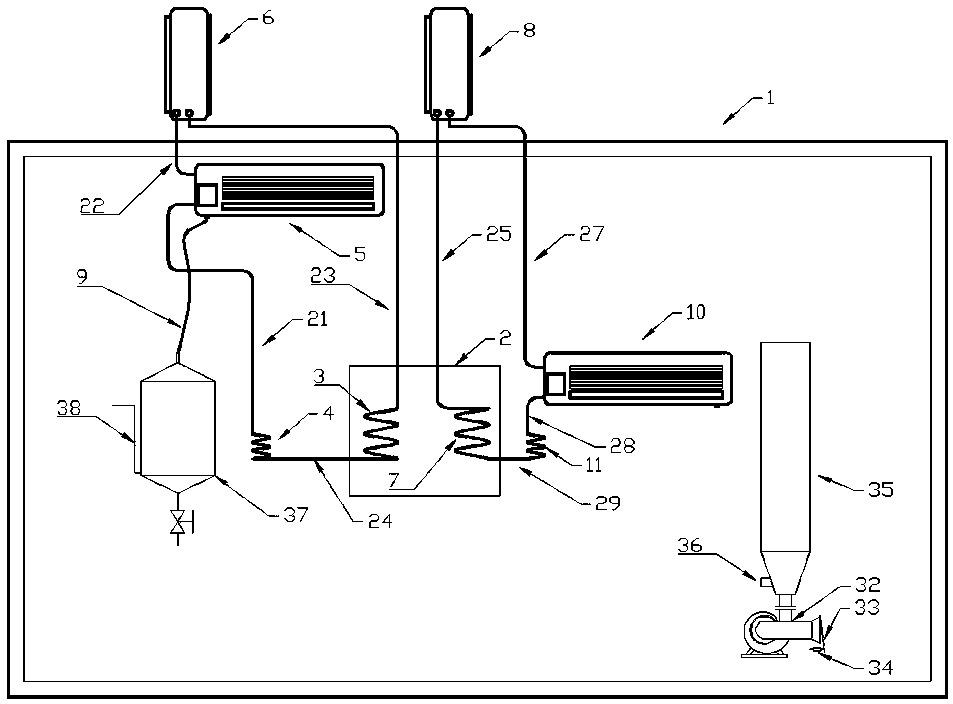

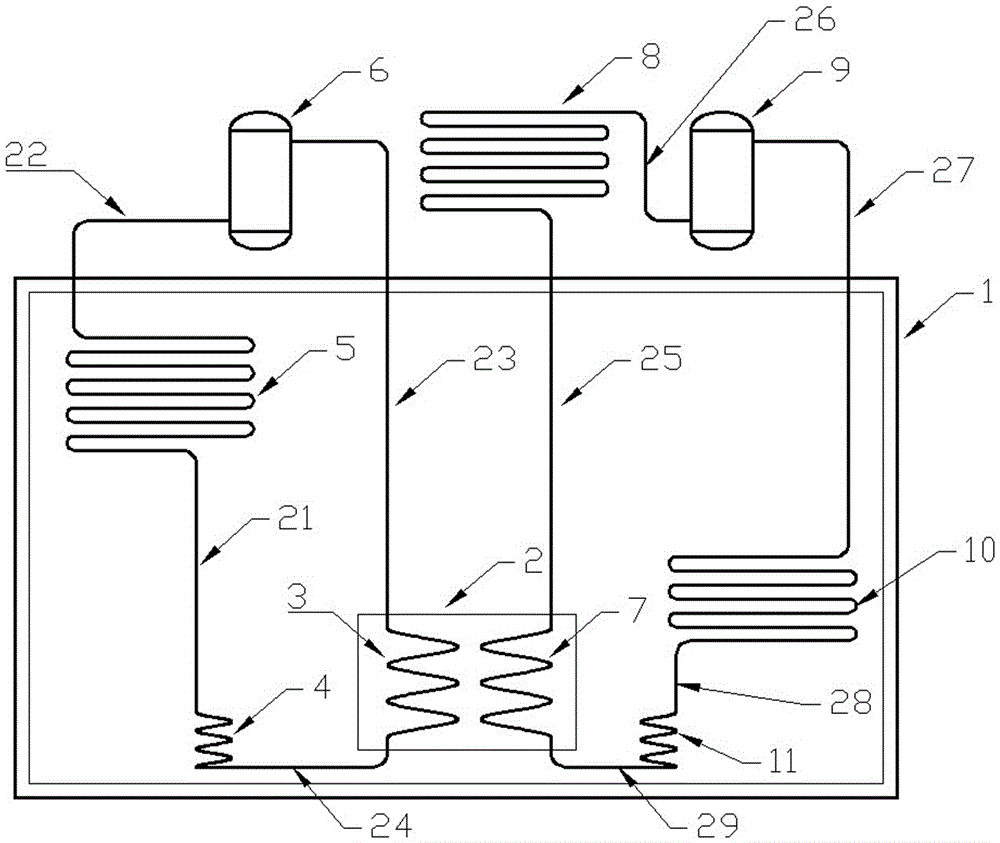

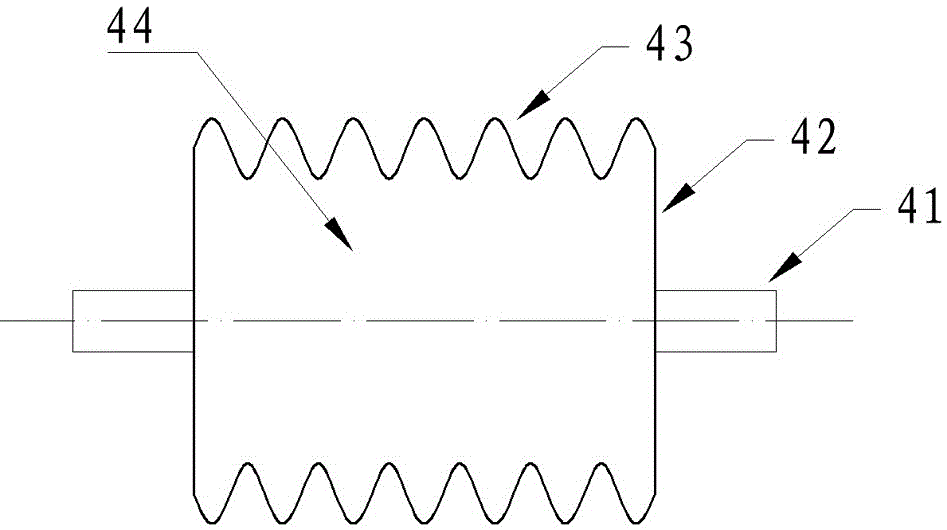

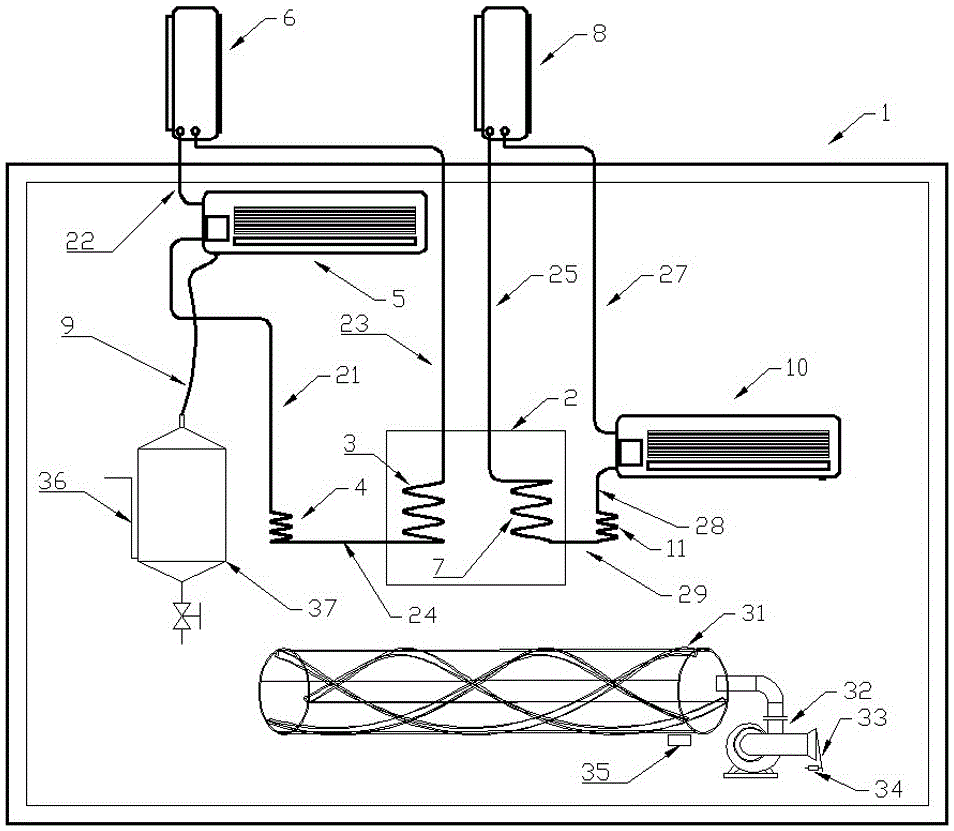

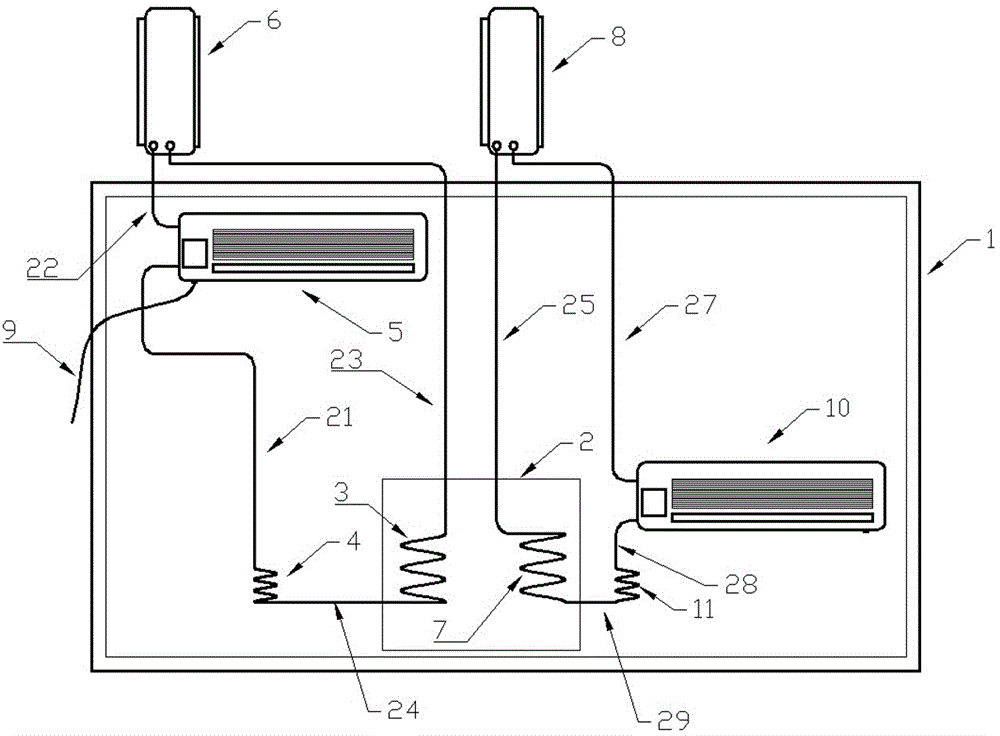

Helix ribbon type zero-discharge gardenia essential oil extracting device

InactiveCN106221918ARealize the collectionZero emissionEssential-oils/perfumesThermal insulationGardenia

The invention discloses a helix ribbon type zero-discharge gardenia essential oil extracting device. A spiral pipe (A) and a spiral pipe (B) are immersed in a water tank provided with thermal insulation enclosure. A compressor (A), the spiral pipe (A), a capillary (A), a refrigeration air conditioner inner machine, and related pipelines form a thermal pump circulation dehumidifying system (A). A heating air conditioner outer machine, a heating air conditioner inner machine, a capillary (B), the spiral pipe (B), and related pipelines form a thermal pump circulation heating system (B). The system (A) cools the environment in the enclosure and condenses and discharges vaporous water and essential oil. Moreover, the system (A) stores the heat energy released during the process of cooling and condensation of vaporous water and essential oil in the water tank. The system (B) heats the environment in the enclosure, gasifies water and essential oil of gardenia to introduce gasified water and essential oil into the enclosure, and absorbs the heat energy stored in the water tank by the system (A). The systems (A) and (B) works alternatively to evaporate, condense and discharge water and essential oil of gardenia, and stores and uses heat energy in the water tank. Compared with the prior art, the energy consumption is largely reduced, and the loss of gardenia essential oil is nearly zero.

Owner:HUNAN SHINEWAY ENTERPRISE

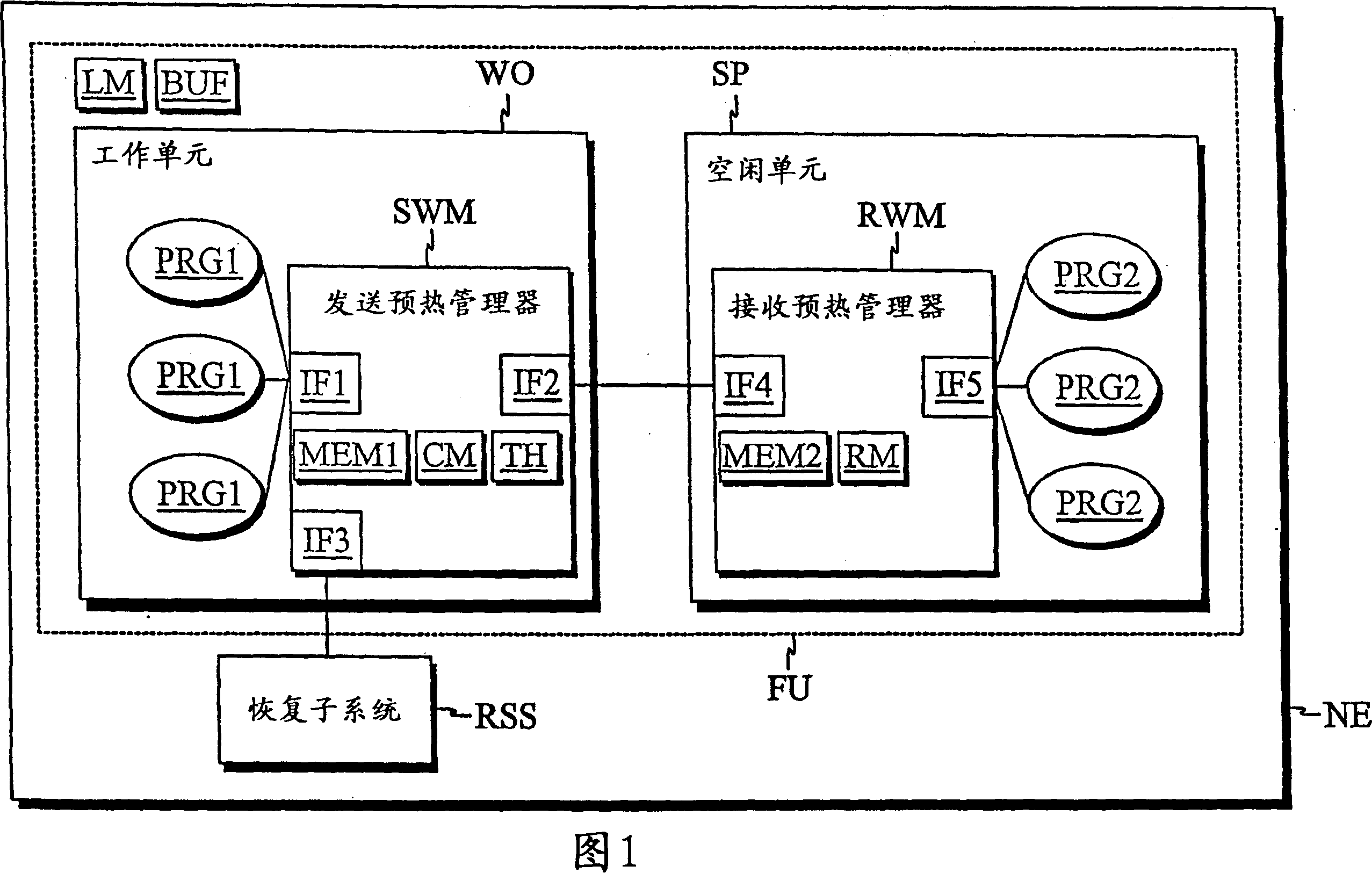

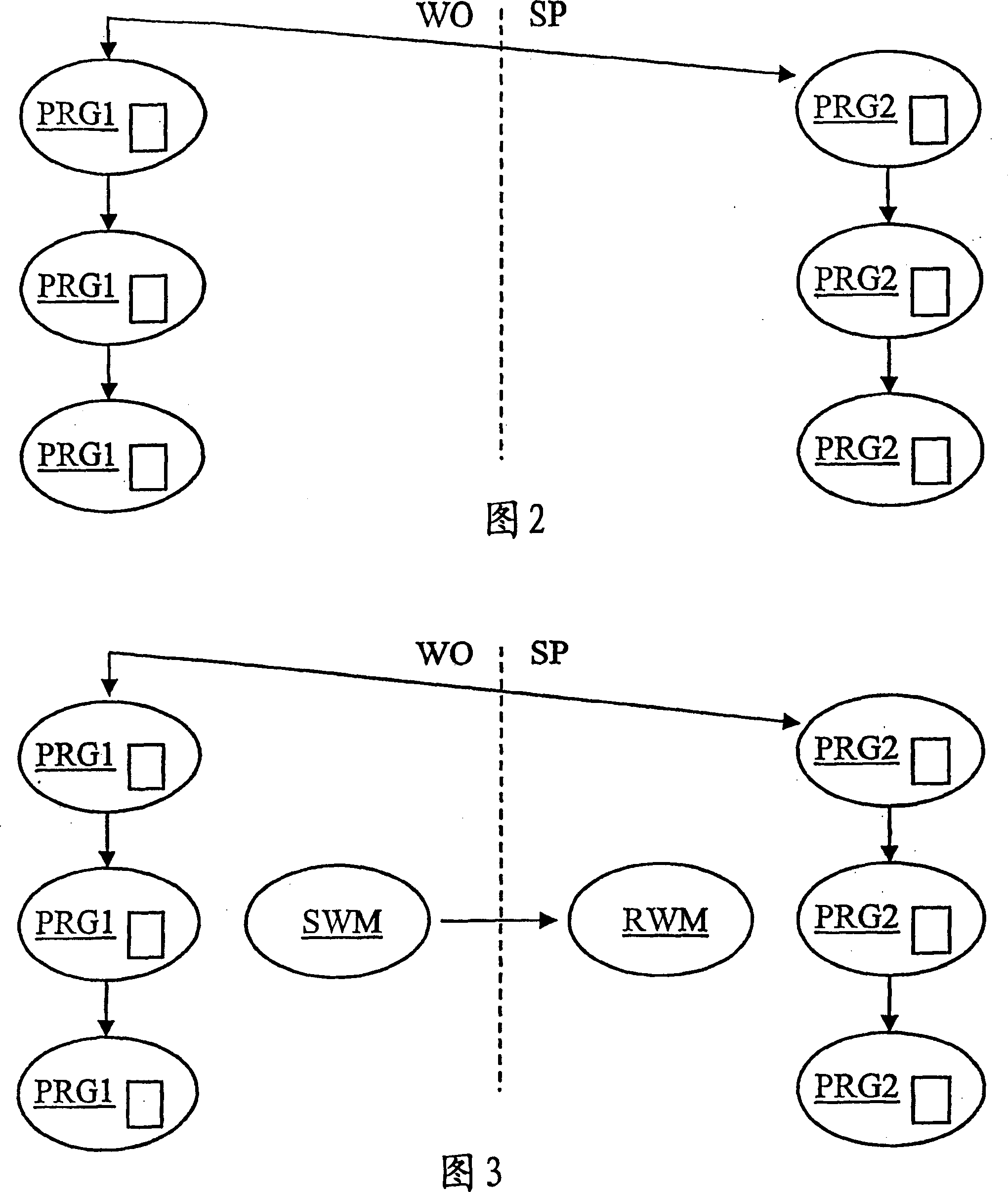

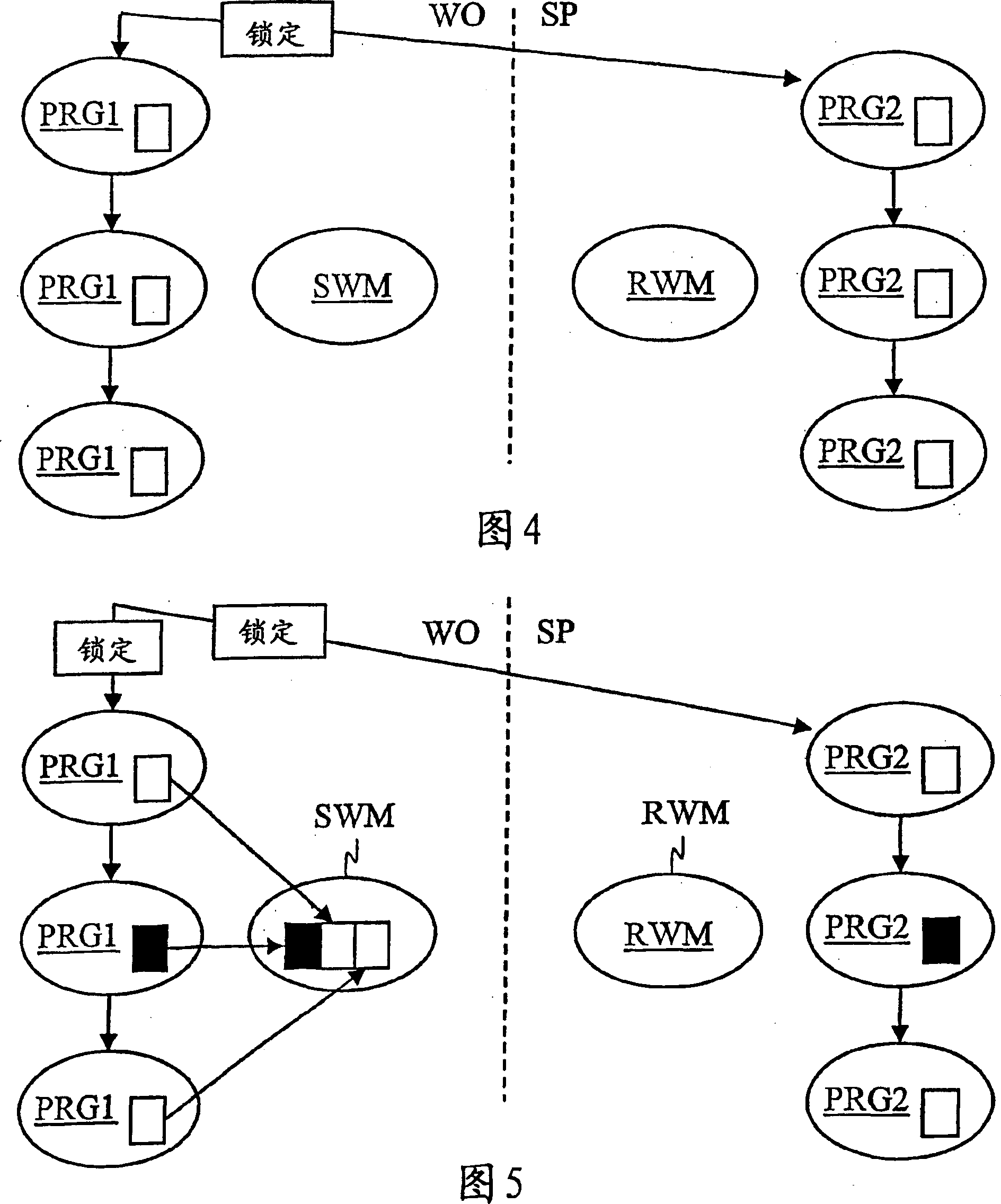

Warming large dynamic data in redundant functional unit

InactiveCN100363902CWarm up wellShorten the timeRedundant operation error correctionRedundant hardware error correctionWork unitDynamic data

Owner:NOKIA CORP

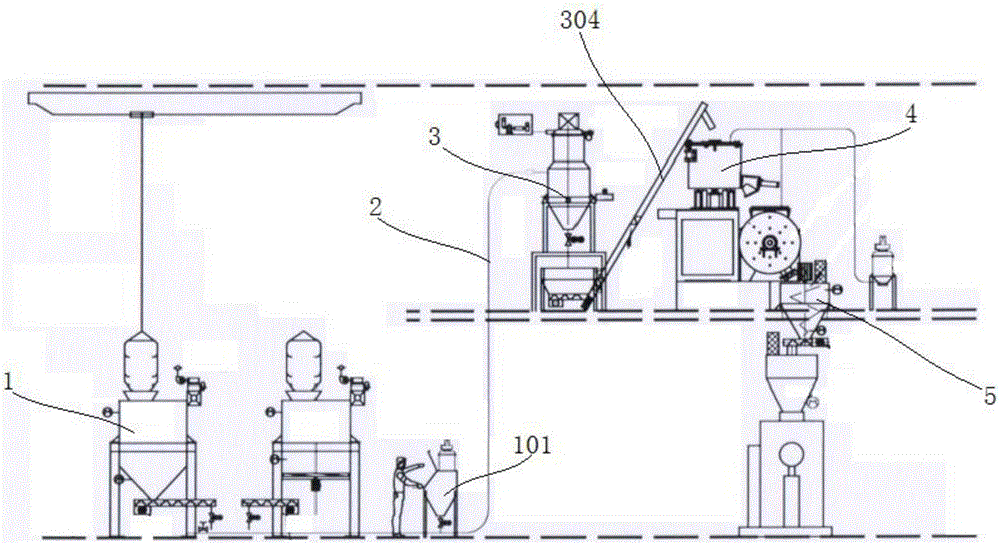

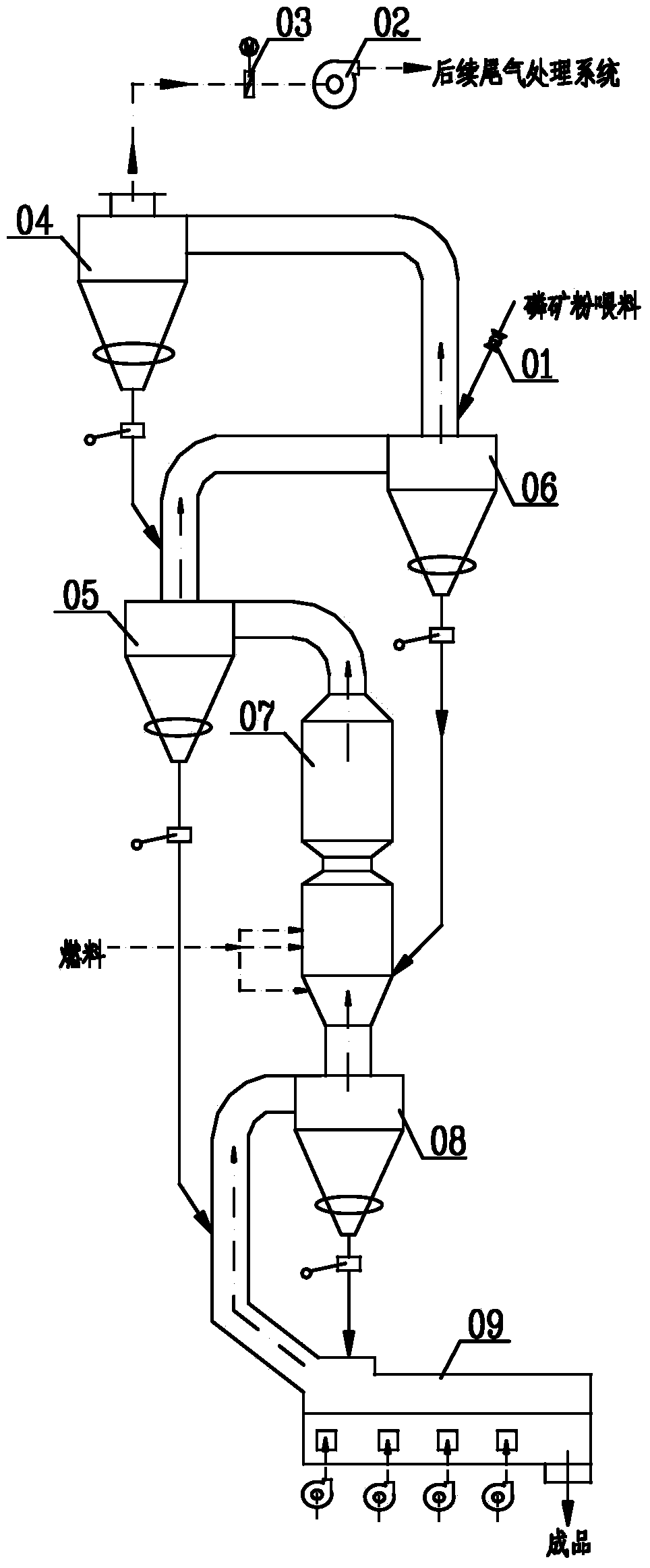

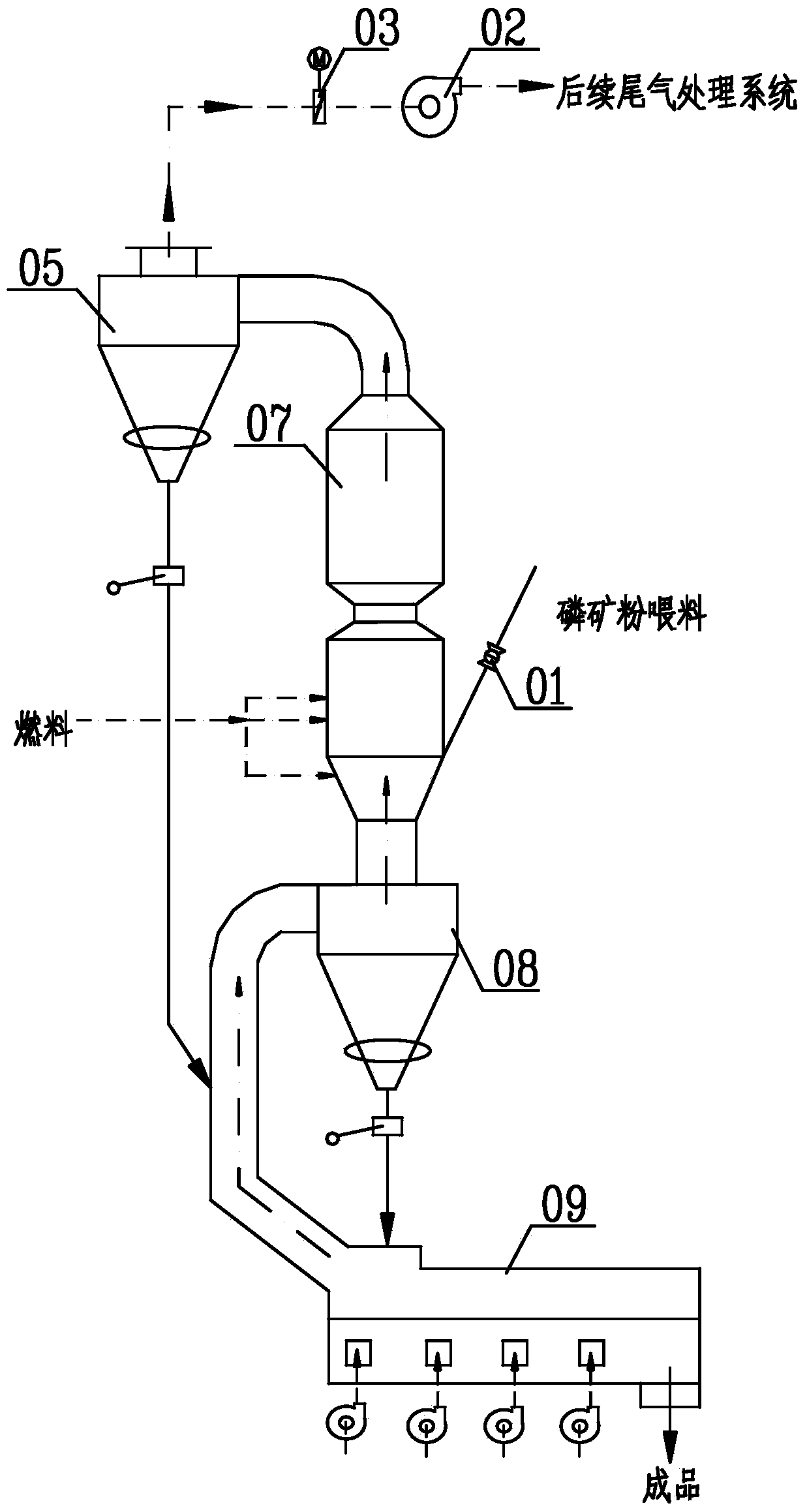

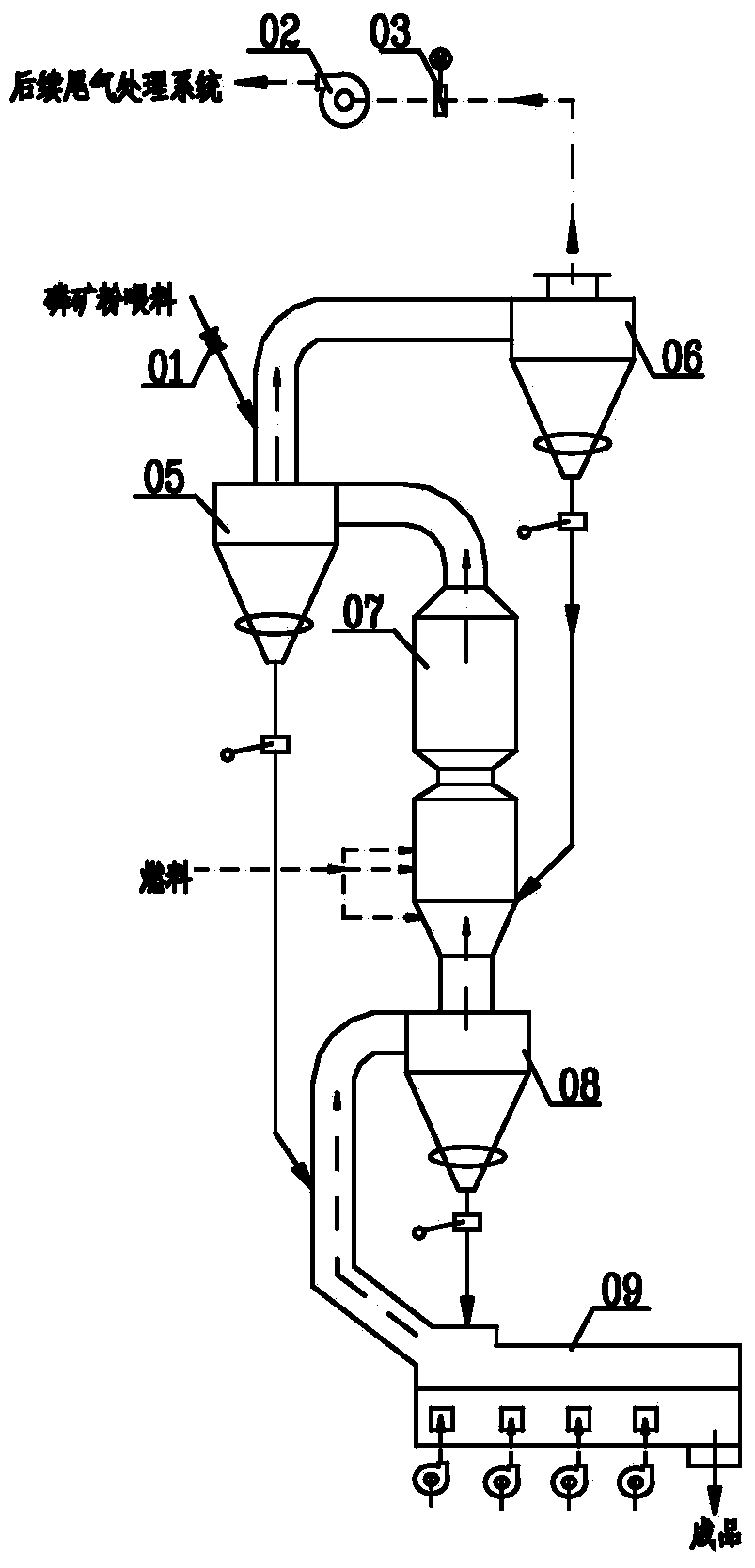

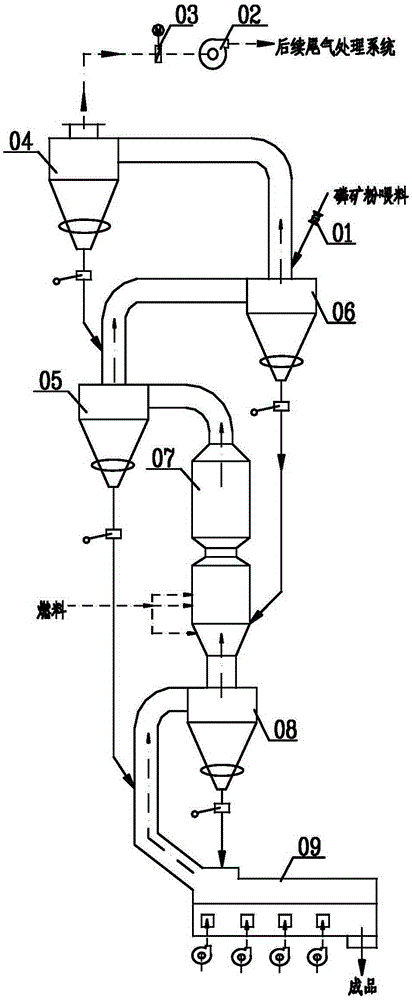

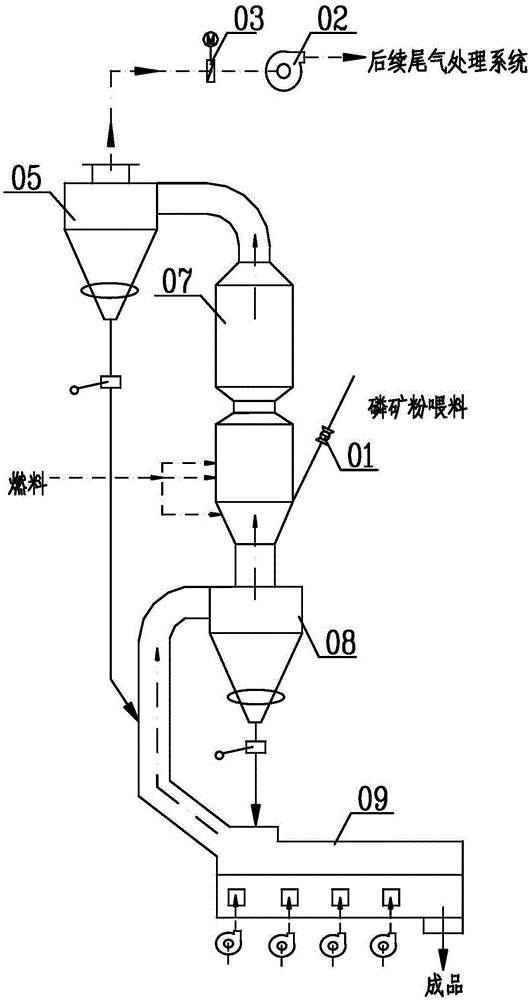

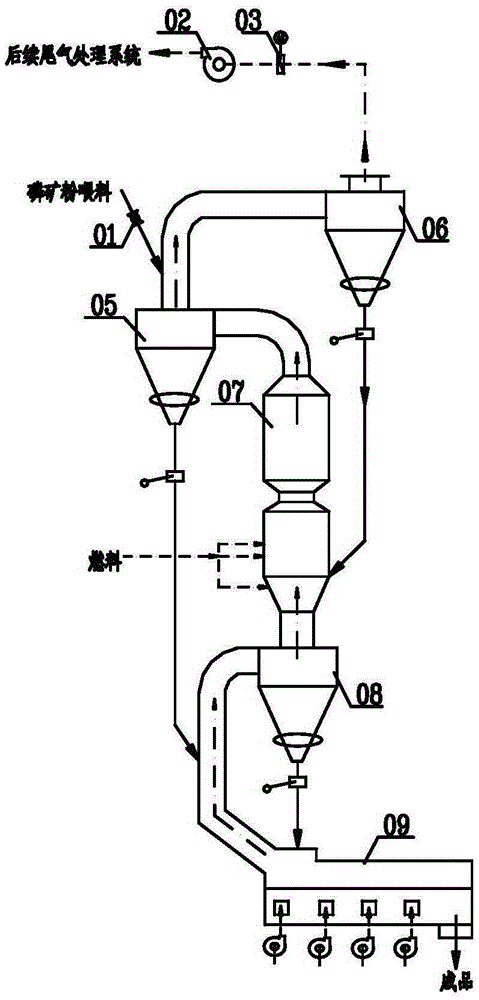

Phosphorite decarburization calcination device

The invention discloses a phosphorite decarburization calcination device and belongs to the field of phosphorite decarburization calcination. The phosphorite decarburization calcination device comprises a flue gas heat recovering and phosphorite powder preheating section, a phosphorite powder fluidized calcination decomposition section and a phosphorite clinker cooling and heat recovery section which are sequentially communicated, wherein the flue gas heat recovering and phosphorite powder preheating section comprises at least three stages of gas-solid separators which are communicated, the phosphorite powder fluidized calcination decomposition section is a material scattering and fluidized calcination device, and the phosphorite clinker cooling and heat recovery section comprises an air cooling device and at least one stage of gas-solid separator which are communicated. The phosphorite decarburization calcination device disclosed by the invention has the advantages that the carbonate decomposition rate is high, the phosphorus recovery rate of the subsequent process can be greatly improved and the effects of energy saving and consumption reduction are remarkably realized.

Owner:成都建筑材料工业设计研究院有限公司

Chinese chestnut acanthosphere drying and shelling device

InactiveCN106072710AReduce energy lossReduce drying energy consumptionFood processingClimate change adaptationHeating systemZero emission

The invention discloses a Chinese chestnut acanthosphere drying and shelling device. A water tank is arranged in a heat-preservation enclosure; water is injected into the water tank to immerse a spiral coiled pipe A and a spiral coiled pipe B; a heat pump circulating dehumidification system A is composed of a compressor A, the spiral coiled pipe A, a capillary tube A, a refrigeration air-conditioning indoor unit and related pipelines; a heat pump circulating heating system B is composed of a heating air-conditioning outdoor unit, a heating air-conditioning indoor unit, a capillary tube B, the spiral coiled pipe B and related pipelines; the system A and the system B alternately work to realize evaporation, condensation and emission of the moisture of Chinese chestnuts and the storage and utilization of heat in the water tank; the heat-preservation enclosure is internally provided with a sieve hole rotary barrel for storing Chinese chestnut involucres and the sieve hole rotary barrel is internally provided with a spiral band; a vibration conveyor is arranged below the sieve hole rotary barrel; a blanking hole of the vibration conveyor is connected with an air blower through an air blowing bucket. Compared with an existing gas-state dehumidifying and drying manner, the energy consumption is greatly reduced and zero emission of refrigeration and dehumidification heat can be realized; a shelling manner of the sieve hole rotary barrel internally provided with the spiral band is very simple and ingenious.

Owner:JISHOU UNIVERSITY

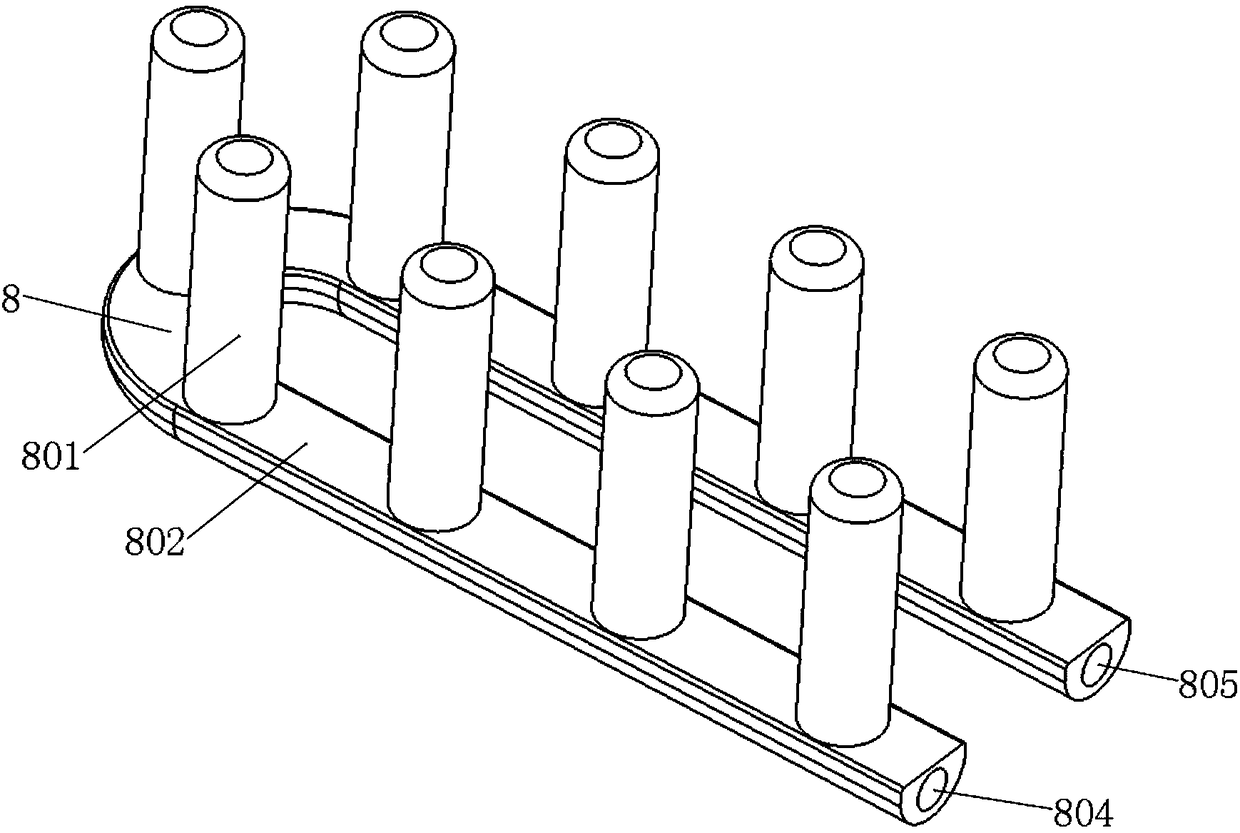

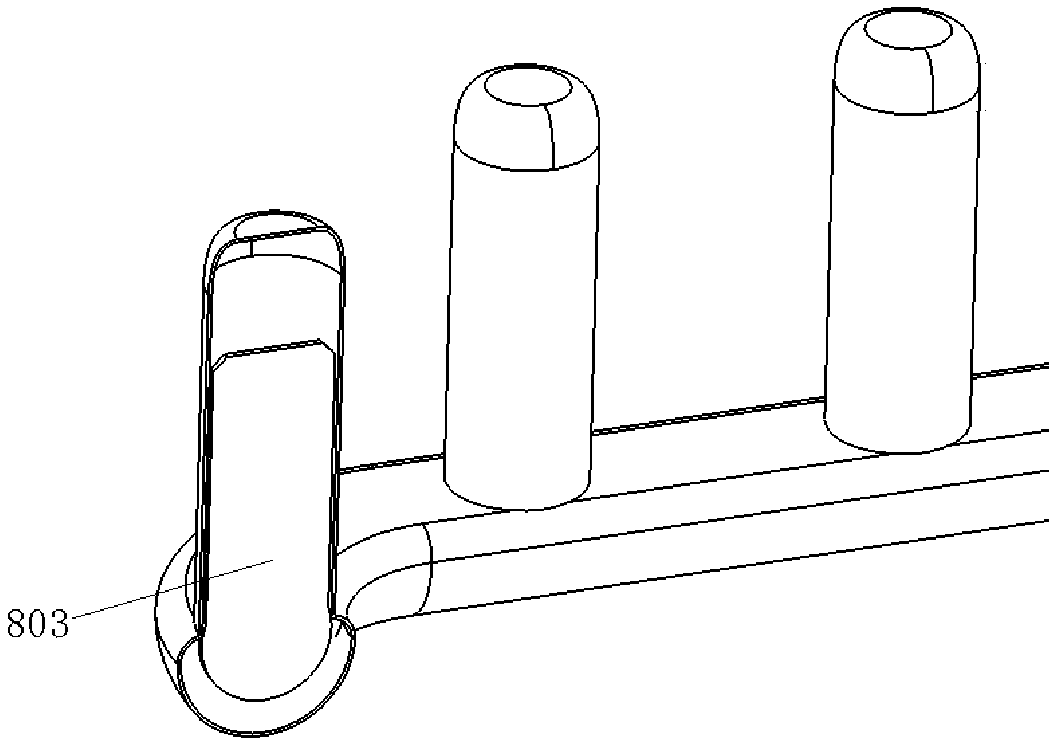

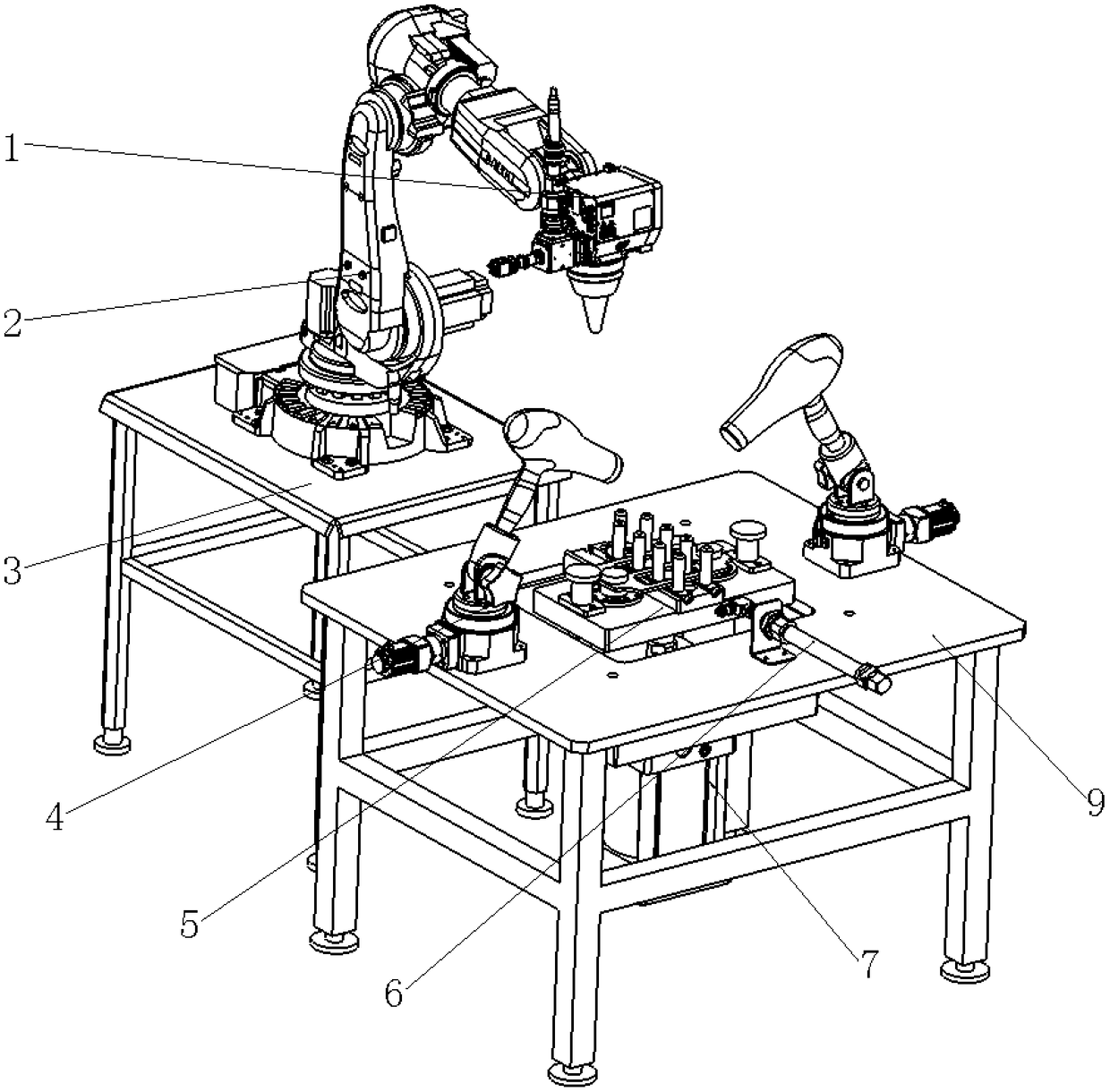

Laser welding and testing integrated method for condensation pipe

ActiveCN108581202AAchieve integrationImplement testLaser beam welding apparatusShielding gasEngineering

The invention provides a laser welding and testing integrated method for a condensation pipe. The method comprises the steps that a welded condensation pipe workpiece is assembled and is clamped and fixed, a U-shaped pipe is inflated with protective gas, and a laser machining head is moved to the joint position; a welding laser beam is output, a multi-freedom-degree mechanical arm is used for controlling the movement of the laser machining head, a focusing laser beam conducts one-circle scanning along the stand column pipe installing hole outline position, and an integral annular welding lineis formed; in the scanning process, the laser power is adjusted in real time, and a laser ring welding line is obtained; through an automatic lifting device, the condensation pipe workpiece obtained after welding is immersed in water, air tightness of the condensation pipe workpiece under the standard testing air pressure is tested, and when points of solder skips are found, welding is conducted again; or otherwise, hot air is adopted for blowing-dry after automatic elevating. According to the laser welding and testing integrated method for the condensation pipe, integrated and automatic laserwelding and testing and online welding defect repairing of the U-shaped condensation pipe are achieved, and the technical problems about automatic welding and online automatic welding line quality testing of the kind of components for a long term are solved.

Owner:常州市托耐多焊割科技有限公司

Automatic liquid separation fluidized bed type jasmine essential oil extraction device

The invention discloses an automatic liquid-separating boiling bed-type jasmine flower essential oil extraction apparatus. According to the essential oil extraction apparatus, a spiral coil A and a spiral coil B are immersed into a water tank of an insulated enclosure; a group A heat pump cycle dehumidifying system is formed by a compressor A, the spiral coil A, a capillary tube A, a refrigeration air conditioner internal unit and the relative pipelines; a group B heat pump cycle dehumidifying system is formed by a heating air conditioner external unit, a heating air conditioner internal unit, a capillary tube B, the spiral coil B and the relative pipelines; the A system realizes cooling in the insulated enclosure as well as condensation discharge of vaporous water and essential oil, and stores the heat released from cooling and condensation of the vaporous water and the essential oil in the water tank; the A system realizes heating in the insulated enclosure and gasification of moisture and essential oil in the jasmine flower to the insulated enclosure, and can absorb the heat stored in the water tank by the B system; the A system and the B system alternatively operate, so that evaporation of the moisture and the essential oil in the jasmine flower, condensation and discharge, and the storage and utilization of heat in the water tank can be realized, compared with the prior art, the energy consumption is greatly reduced, and the loss of the jasmine flower essential oil is almost zero.

Owner:湖南中茂生物科技有限公司

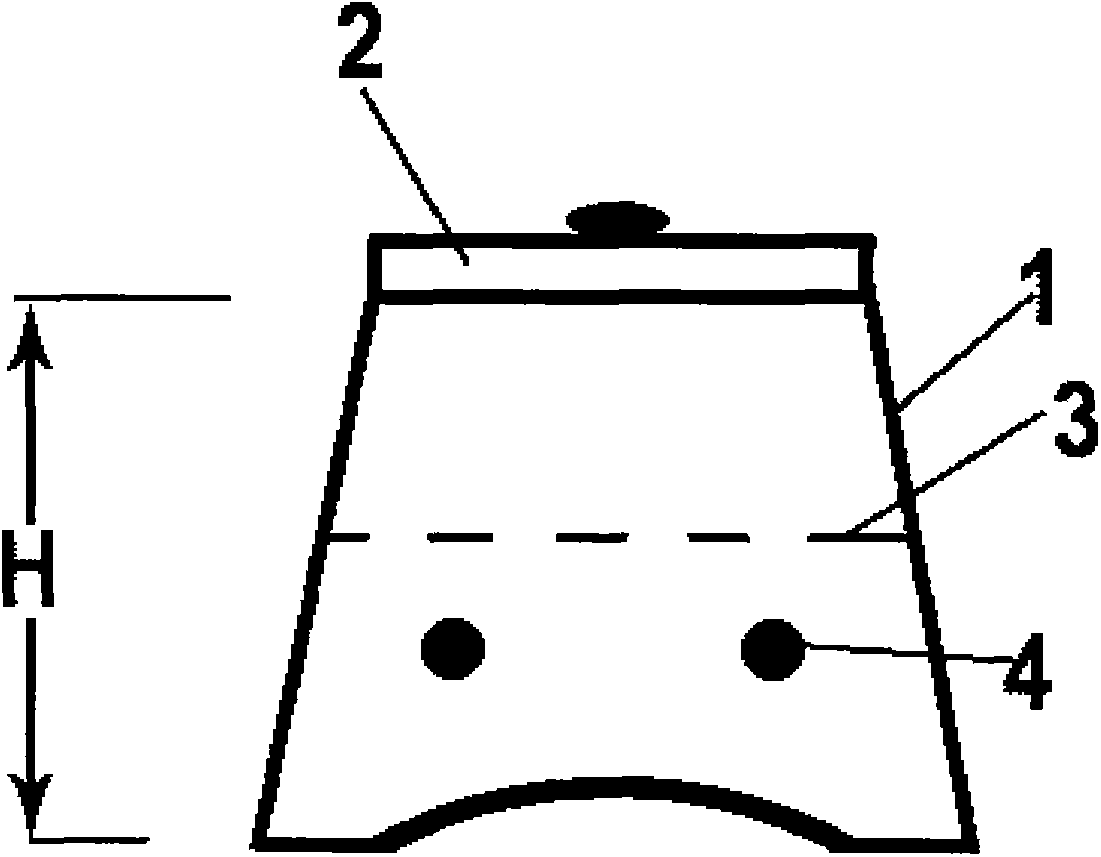

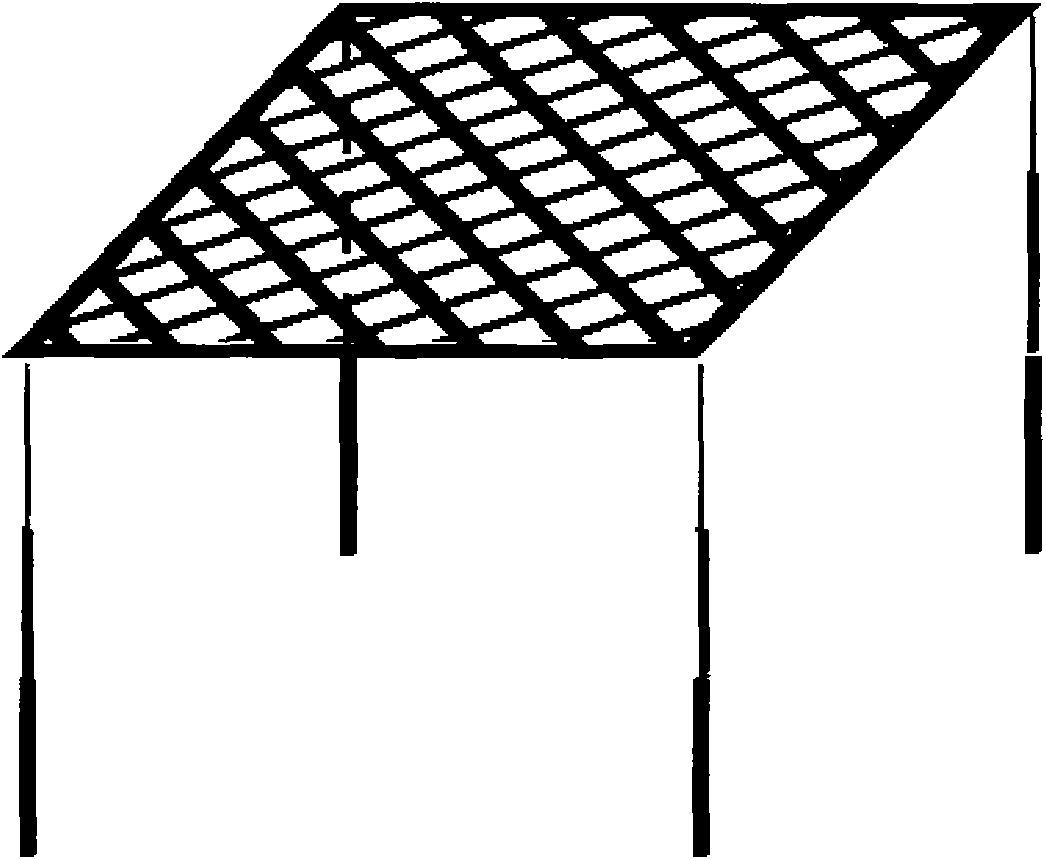

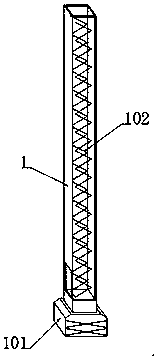

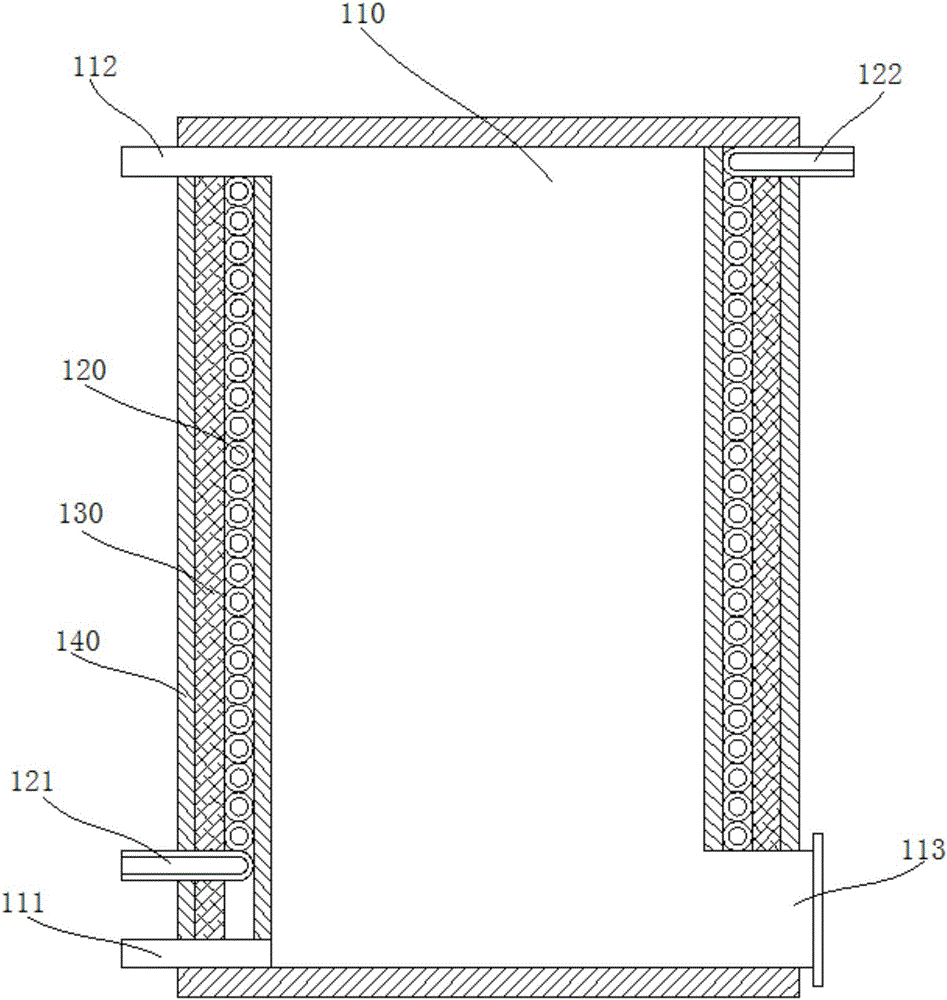

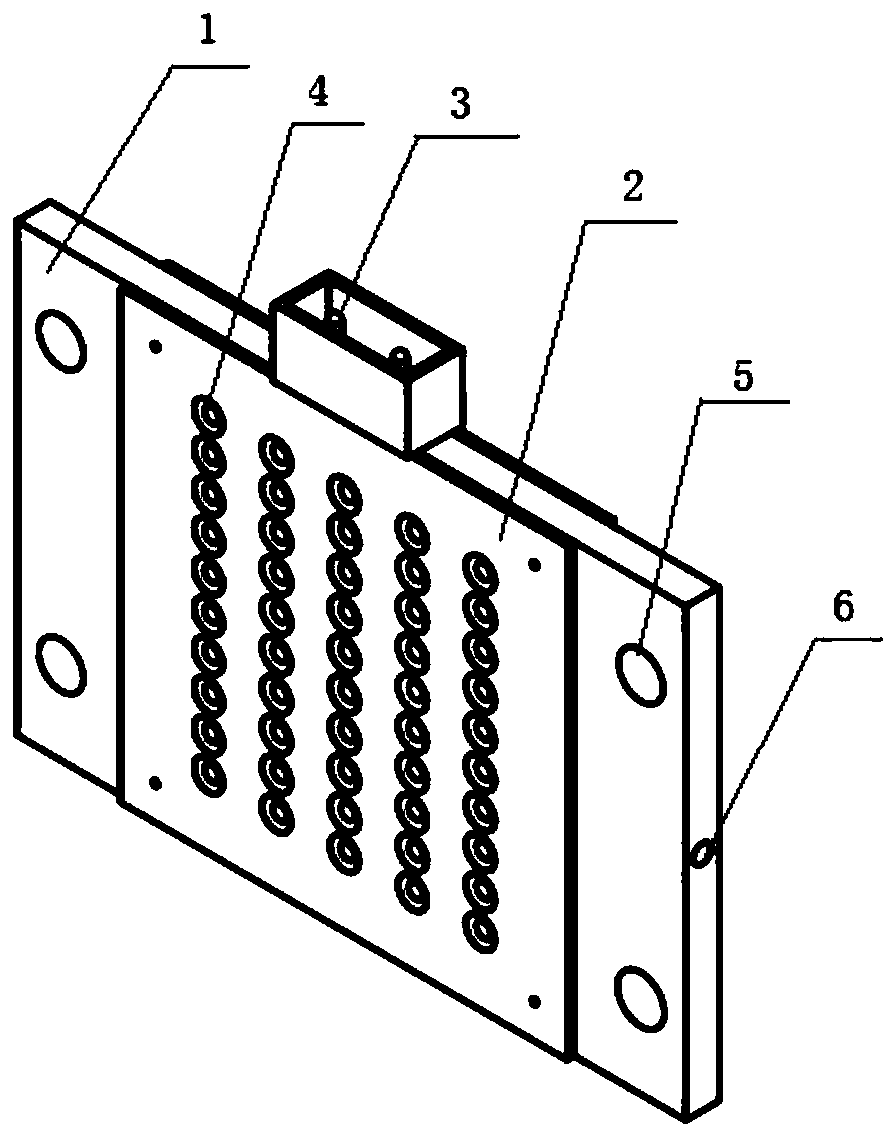

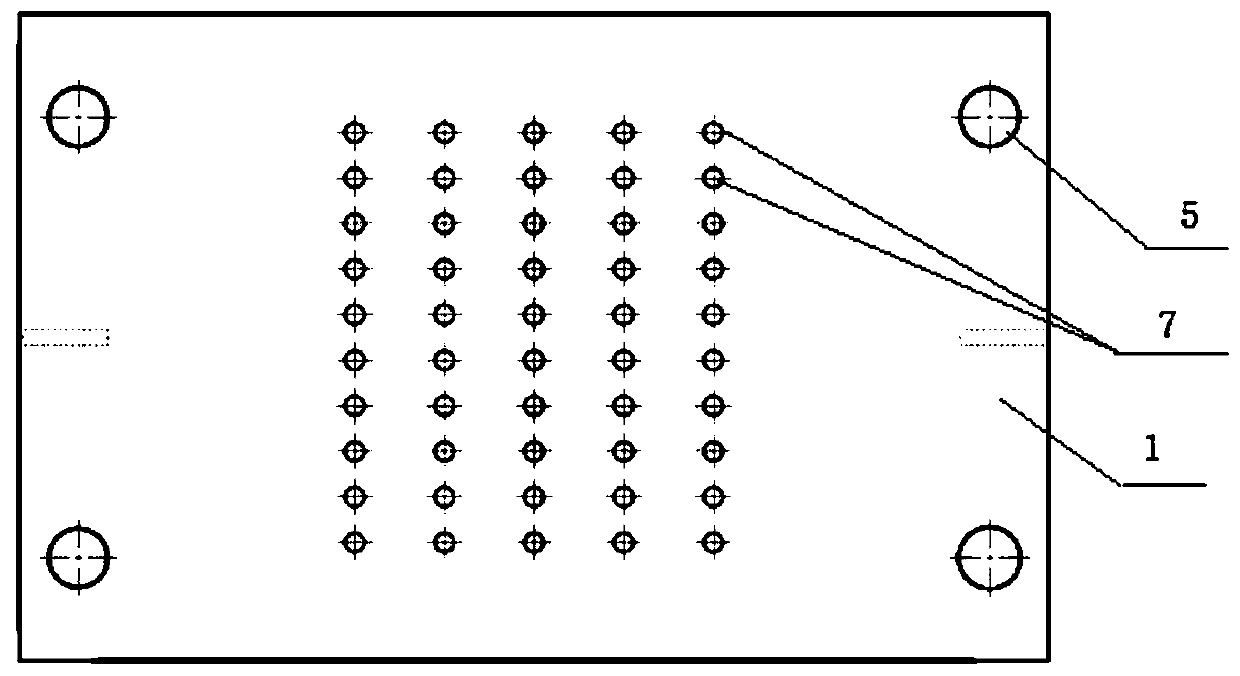

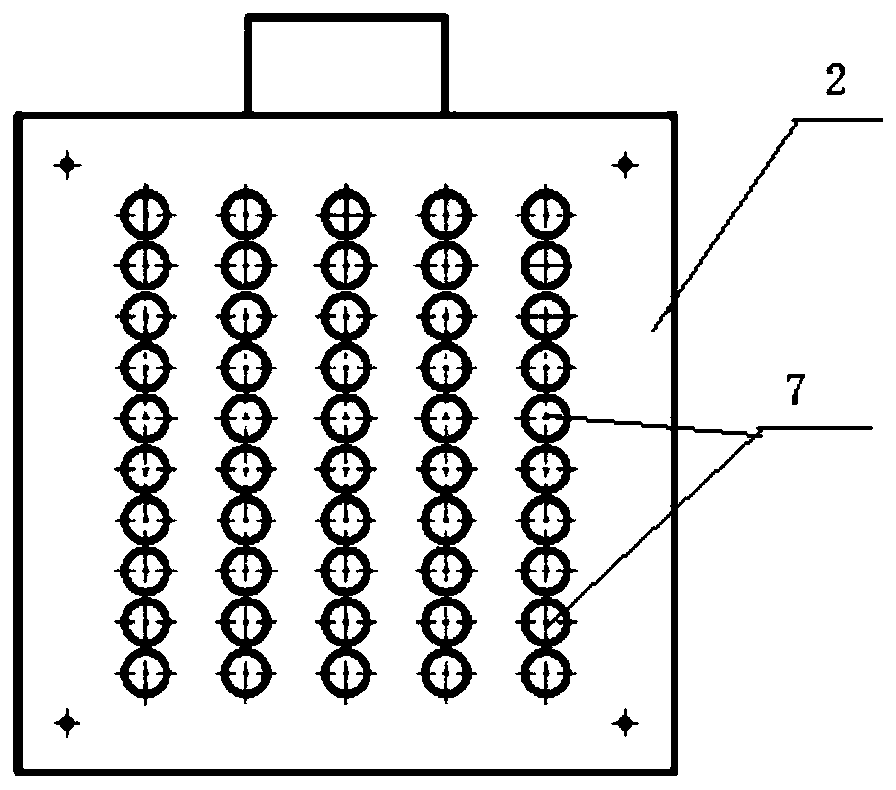

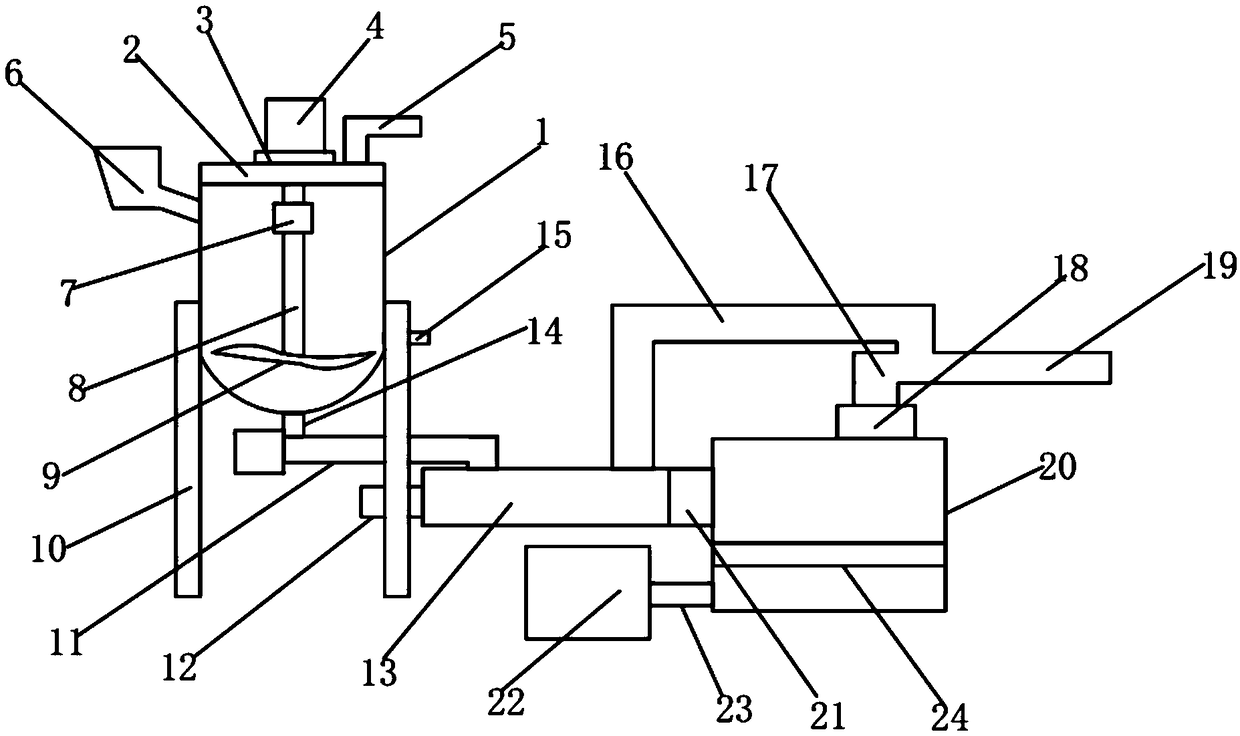

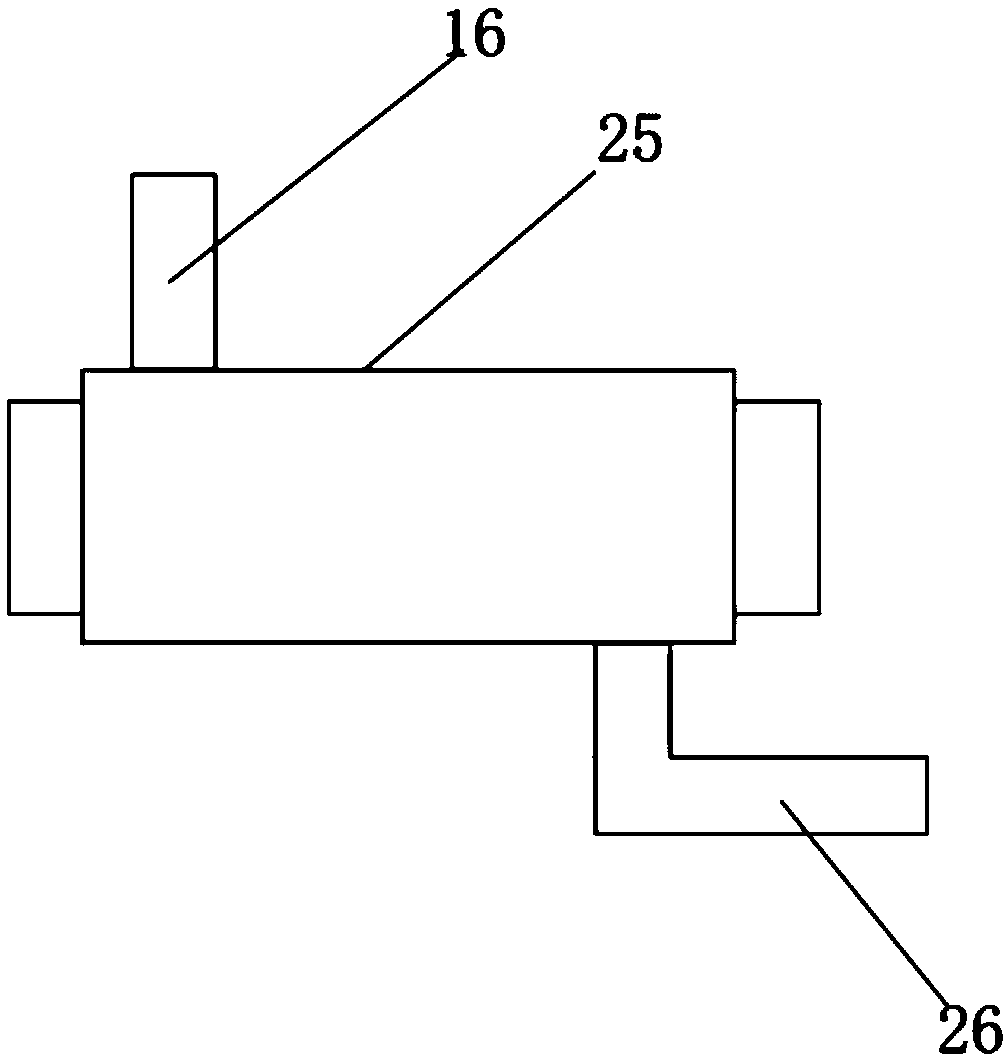

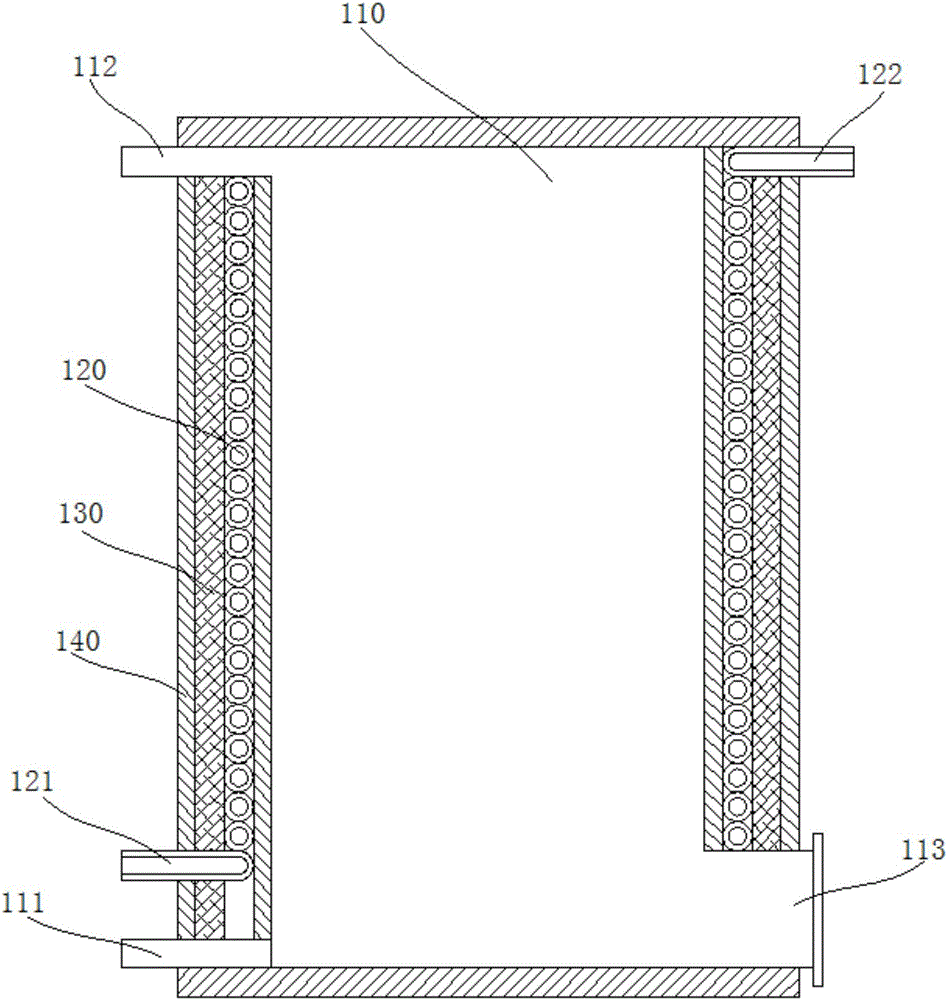

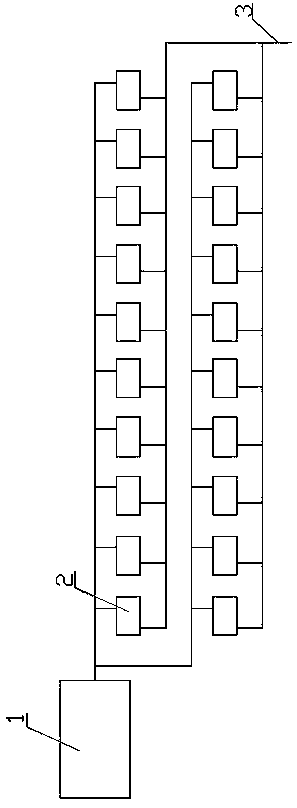

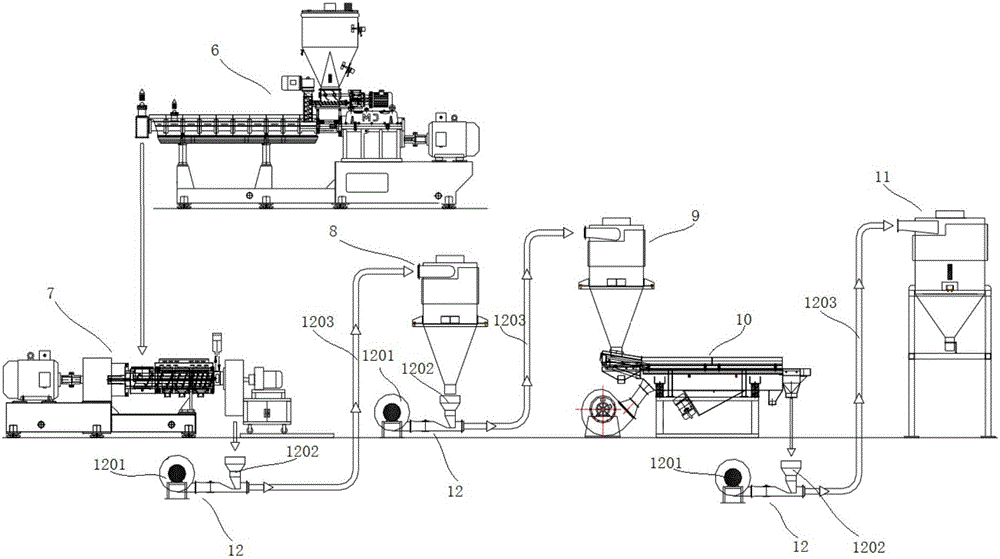

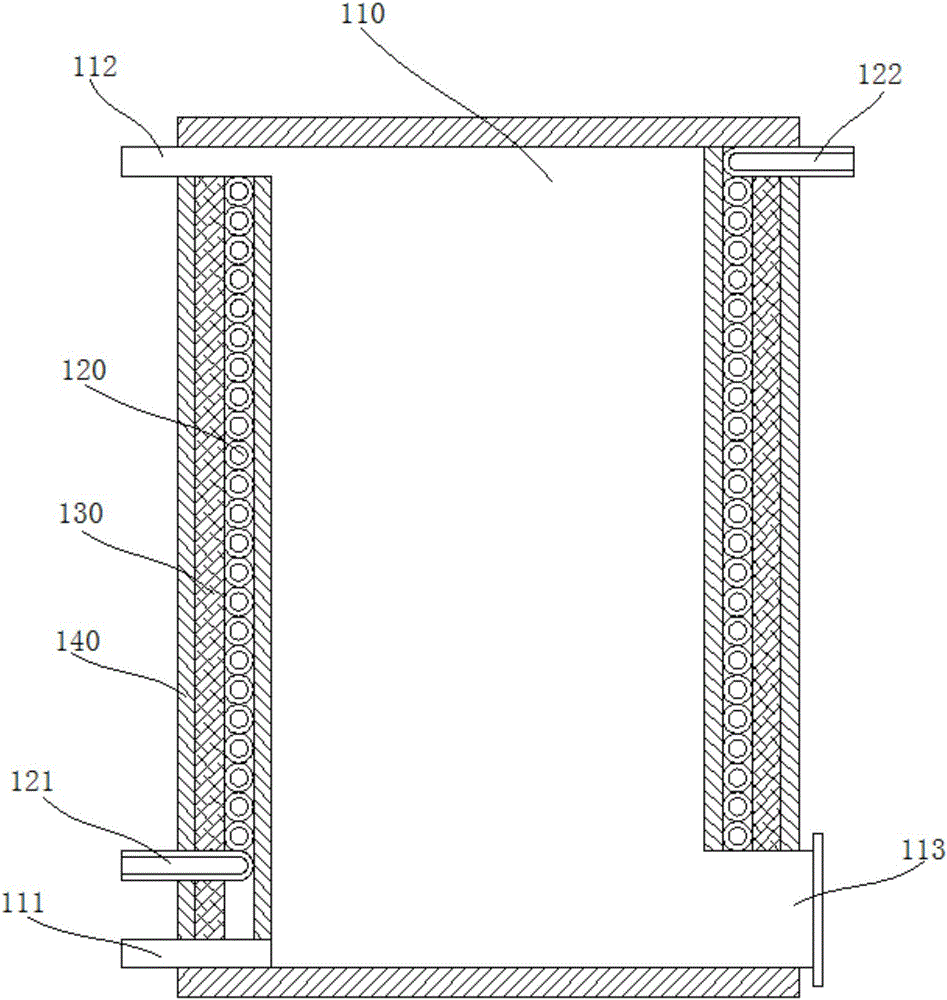

Fiber preheating device for pultrusion of composite material products and pultrusion preheating method thereof

The invention discloses a fiber preheating device for pultrusion of composite material products and a pultrusion method thereof. The fiber preheating device for pultrusion of the composite material products comprises a tetrafluoroethylene glue-extruding plate (1), an electrical heating aluminium plate (2) which is connected and fixed to the tetrafluoroethylene glue-extruding plate (1) through bolts and a power supply plug (3) connected with the upper portion of the electrical heating aluminum plate (2). Counter bores of the same number and size are formed in the tetrafluoroethylene glue-extruding plate (1) and the electrical heating aluminum plate (2) correspondingly. Little spouts (4) penetrate through the counter bores in the tetrafluoroethylene glue-extruding plate (1) and the electrical heating aluminum plate (2). Through holes (5) matched with pre-solidifying mold tools are formed in the outer periphery of the tetrafluoroethylene glue-extruding plate (1). Temperature measuring holes are formed in two side faces of the electrical heating aluminum plate (2) respectively. By means of the fiber preheating device for pultrusion of the composite material products, the pultrusion speed in the pultrusion production process can be effectively improved; the device has a great preheating effect on glass fiber pre-impregnated with resin; and meanwhile, the mechanical property of pultrusion composite material products can be improved, and efficiency and benefits of pultrusion production are improved.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

Chemical material crushing and pelletizing machine with tail gas treatment function

InactiveCN108745200AWarm up wellKeep warmGranulation by material expressionElectric machineryExhaust gas

The invention discloses a chemical material crushing and pelletizing machine with a tail gas treatment function. The chemical material crushing and pelletizing machine comprises a stirring tank body;the upper end of the stirring tank body is open; an upper cover is buckled at an opening position at the upper end of the stirring tank body; a motor base is welded to the upper cover; a motor is fixed on the motor base through screws; a center hole is formed in the center of the upper cover; a motor shaft of the motor is arranged vertically downwards; the motor shaft of the motor movably penetrates into the stirring tank body from the center hole in the upper cover. A material pipe can be preheated and be subjected to heat preservation well by utilizing high-temperature waste gas, and materials in the material pipe can be heated and also can be subjected to heat preservation at the moment; for cold regions, the whole equipment does not need to use additional heat-insulating equipment, sothat energy consumption is reduced, the phenomenon that the materials are frozen is avoided, and the entire extrusion process is smoother.

Owner:NANAN CHUANGPEI ELECTRONICS TECH CO LTD

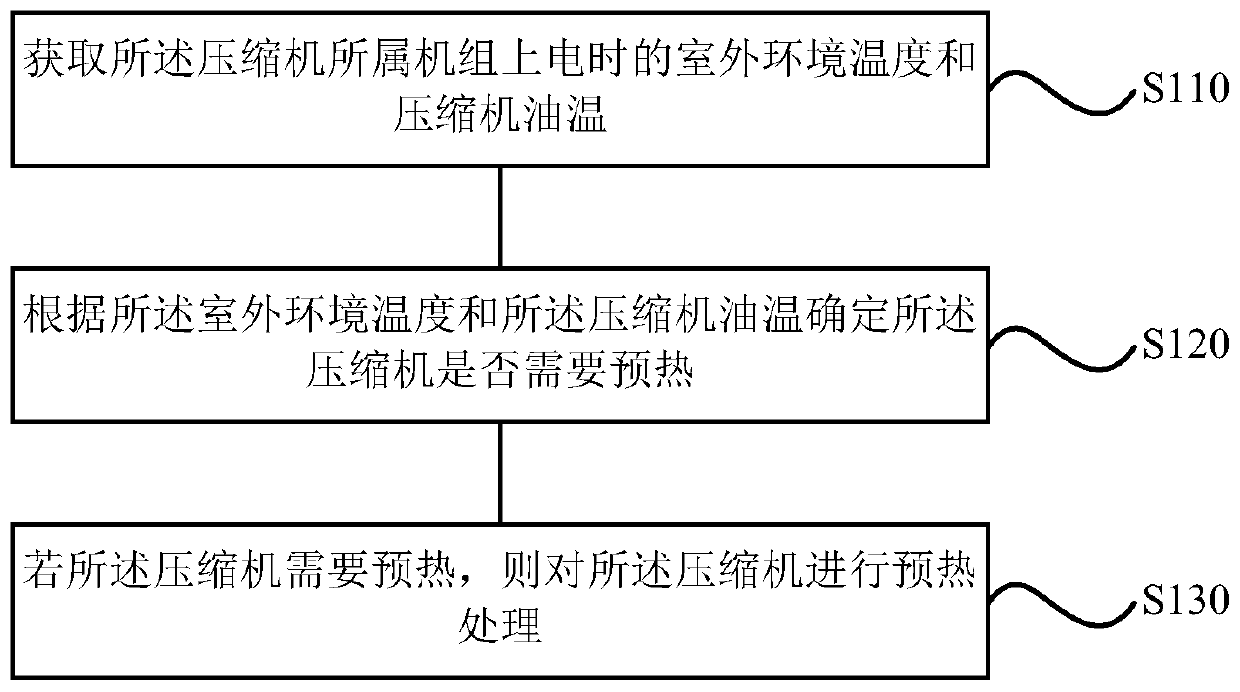

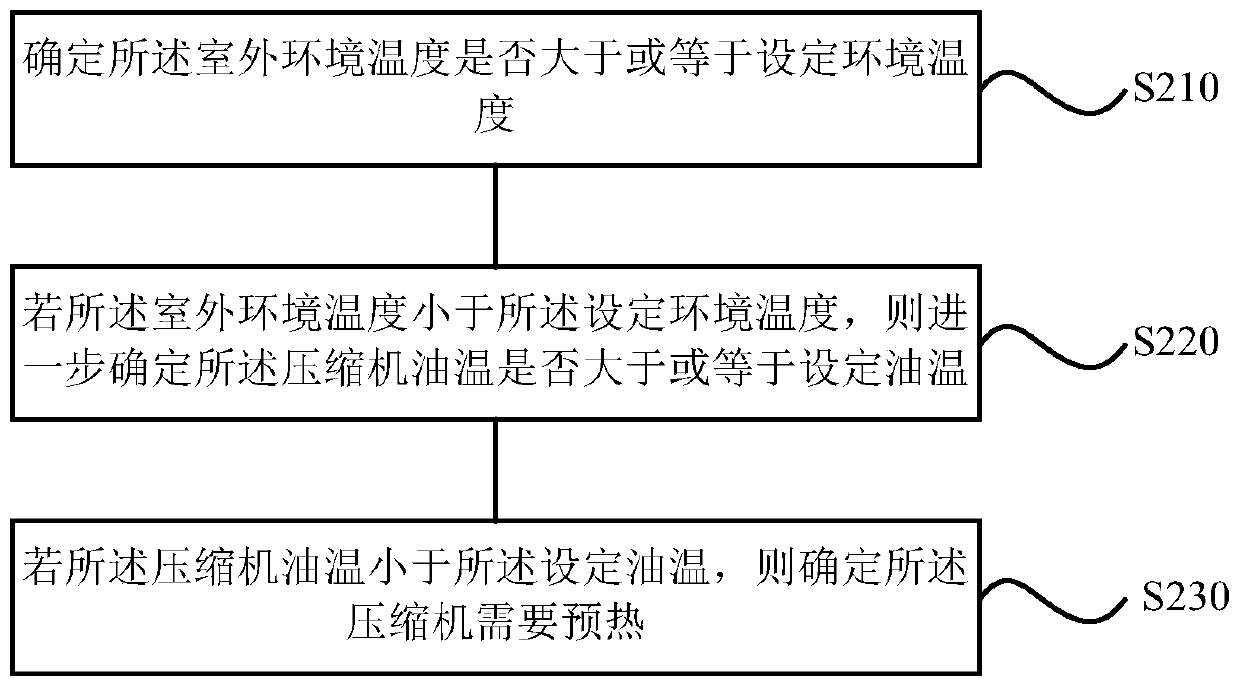

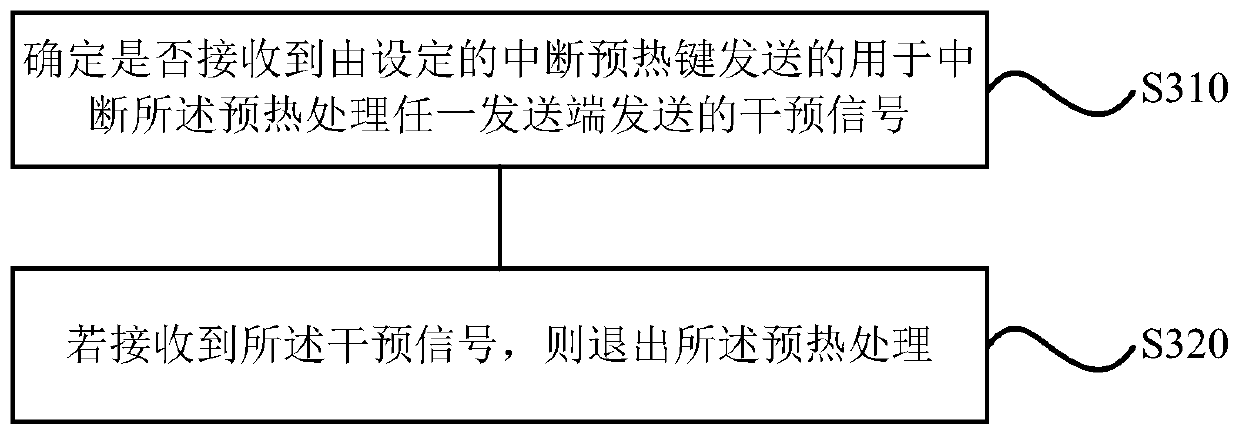

Compressor preheating control method, device, storage medium and air conditioner

ActiveCN109539465BAvoid irreversible damageImprove reliabilityMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsEngineering

The invention discloses a preheating control method and device for a compressor, a storage medium and an air conditioner. The method includes the steps that the outdoor environment temperature and thecompressor oil temperature are obtained when a unit which the compressor belongs to is electrified are obtained; whether the compressor needs to be preheated or not is determined according to the outdoor environment temperature and the compressor oil temperature; and if the compressor needs to be preheated, the compressor is preheated. By means of the scheme, the problem that when the compressorneeds to be preheated, unrecoverable damage will be caused to the unit when the unit is started immediately after being electrified can be solved, and the effect that the unit is not likely to be damaged is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

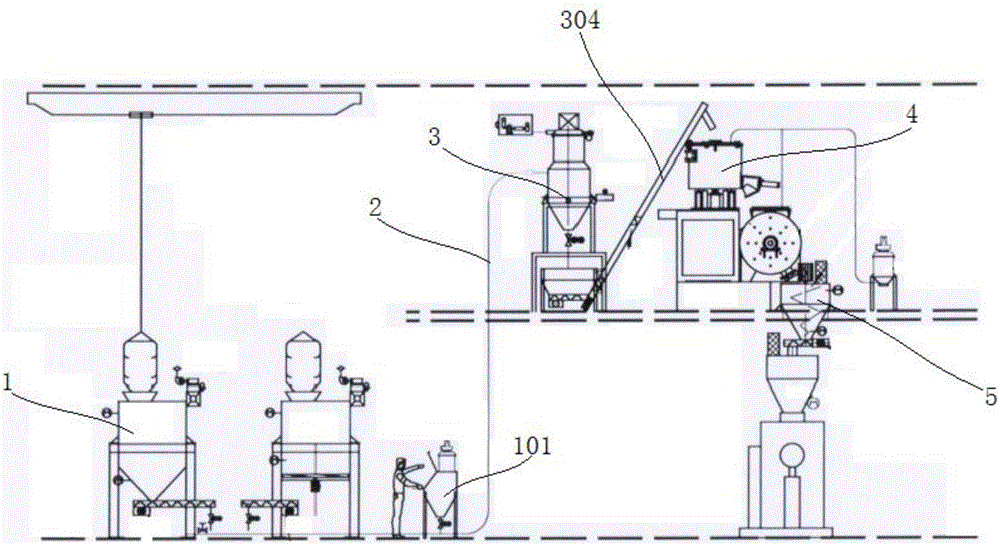

Low-noise plastic production device convenient for raw material preheating

InactiveCN105835255AImprove cooling effectJiagu Gas SeparationDirt cleaningSound producing devicesCycloneLow noise

The invention relates to the technical field of plastic processing equipment, and relates to a low-noise plastic production device convenient for raw material preheating. The low-noise plastic production device comprises a stock bin, a material conveying pipeline, a material weigher, a material mixer, a temporary stock bin, an extruder, a die surface hot-cutting granulator, a first cyclone separator, a second cyclone separator, a vibration sieve and a packaging machine which are sequentially connected, wherein pneumatic conveying systems are arranged among the die surface hot-cutting granulator, the first cyclone separator and the second cyclone separator, a pneumatic conveying system is also arranged between the vibration sieve and the packaging machine, and each pneumatic conveying system comprises a conveying fan, a connection tee and a conveying pipeline; a pipeline main body of the material conveying pipeline is constructed with a heating runner and a charge channel along an axial direction; a sound-isolation cover body is arranged at each conveying fan in a covering manner; and waste gas exhaust ports are arranged at the material mixer, the first cyclone separator and the second cyclone separator, and all the waste gas exhaust ports are connected with a spray tower. The low-noise plastic production device disclosed by the invention is convenient for conveying of plastic processing raw materials.

Owner:DEQING BAISHENG PLASTIC CO LTD

A fire prevention monitoring device for mountainous areas

ActiveCN111337084BPlay the role of fire isolationPlay a protective effectFouling preventionPrintersWind runEngineering

The invention discloses a fire prevention and monitoring device for mountainous areas, which belongs to the technical field of fire prevention and monitoring. A fire prevention and monitoring device for mountainous areas includes a monitoring tower and an operating room fixedly connected to the monitoring tower. A wind speed and direction sensor and a windmill are installed, and a lifting plate is fixedly connected to one side wall of the monitoring tower, and a tower body protection mechanism composed of a tower bottom fireproof cover and a fireproof isolation layer is set at the bottom of the monitoring tower. The bottom fire cover and the fire isolation layer have a certain fire isolation effect on the tower body. By connecting the exhaust pipe on the environmental monitoring box with the blower shield on the thermal imaging camera, the air derived from the environmental monitoring box is The inner wall of the blast shield is led out, coordinated with the diversion tube and the heating mechanism, and effectively dissipates heat from the end face of the lens of the thermal imaging camera through gas or removes the icing layer and frost on the end face of the lens. The camera plays a protective role.

Owner:天立泰科技股份有限公司

Heat pump type drying device

The invention discloses a heat pump type drying device. A water tank is arranged in a heat preserving enclosure; water is injected in the water tank to immerse a spiral coil pipe A and a spiral coil pipe B in the water tank; a compressor A, the spiral coil pipe A, a capillary pipe A, a coil pipe A and relevant pipelines form a heat pump cycle dehumidifying system A; a compressor B, a coil pipe B, a capillary pipe B, the spiral coil pipe B, an outer coil pipe and relevant pipelines form a heat pump cycle heating system B; the system A achieves cooling in the heat preserving enclosure and condensation drainage of vaporous water, and heat released during cooling and condensation of the vaporous water is stored in the water tank; the system B achieves temperature rising in the heat preserving enclosure and the operation of vaporizing water in materials into the heat preserving enclosure and absorbs the heat stored in the water tank by the system A; and the system A and the system B alternately work to achieve evaporation, condensation and drainage of the water in the materials in the heat preserving enclosure and storage and utilization of the heat in the water tank. Compared with an existing gaseous state dehumidifying and drying manner, energy consumption is greatly reduced, and zero emission of refrigerating and dehumidifying heat can be achieved.

Owner:湘西银湘农业科技有限责任公司 +1

Preparation method and application for solid beverage

ActiveCN103859547BAvoid volatile lossExtract maximumNatural extract food ingredientsFood ingredient functionsBiotechnologyMedicinal herbs

Owner:广东旗峰健康产业有限公司

Fluidized bed type zero-emission extraction device for neroli essential oil

ActiveCN106281696ARealize the collectionZero emissionEssential-oils/perfumesFluidized bedEvaporation

The invention discloses a fluidized bed type zero-emission extraction device for neroli essential oil, wherein a spiral pipe A and a spiral pipe B are immersed in a water tank of an insulated enclosure; a compressor A, the spiral pipe A, a capillary tube A, a refrigeration air conditioner internal unit and interrelated pipelines form a heat pump circulation dehumidification system A; a heating air conditioner external unit, a heating air conditioner internal unit, a capillary tube B, the spiral pipe B and interrelated pipelines form a heat pump circulation heating system B; according to the heat pump circulation dehumidification system A, cooling in the insulated enclosure and condensate discharge of vaporous water and essential oil are achieved, and heat released by cooling and condensation of the vaporous water and essential oil is stored in the water tank; according to the heat pump circulation heating system B, a temperature rise in the insulated enclosure and gasification of the moisture and essential oil in neroli into the insulated enclosure are achieved, and the heat which is stored in the water tank by the system A is absorbed; the system A and the system B work alternately, so evaporation, condensation and emission of the moisture and essential oil in the neroli are achieved, and storage and utilization of the heat in the water tank are also achieved. Compared with the prior art, energy consumption is greatly reduced, and the loss of the neroli essential oil is almost zero.

Owner:永顺县大丰生态农业开发有限公司

Beef slice dryer with magnetic vibration function

InactiveCN106091603AReduce lossZero emissionMechanical apparatusCondensate preventionEvaporationEngineering

The invention discloses a beef slice dryer with a magnetic vibration function. A water tank is arranged in a heat-preservation enclosure. Water is injected into the water tank for submerging a spiral coil A and a spiral coil B in the water tank. A compressor A, the spiral coil A, a capillary tube A, an indoor unit of a refrigerating air conditioner and relevant pipelines form a heat pump circulating dehumidifying system set A. An outdoor unit of a heating air conditioner, an indoor unit of the heating air conditioner, a capillary tube B, the spiral coil B and relevant pipelines form a heat pump circulating heating system set B. The system A and the system B work alternately for achieving evaporation, condensation and discharging of moistures of beef slices in the heat-preservation enclosure and storage and utilization of heat in the water tank. The heat-preservation enclosure is further internally provided with a magnetism driven screen differential motion and impulse type vibration device and convection fans. Compared with an existing gas-state dehumidifying and drying method, the energy consumption is greatly lowered, and refrigerating and dehumidifying can be achieved with zero heat discharge; and screen vertical differential motion and impulse type vibration are alternately driven by magnetic force, beef slice stirring is particularly facilitated, hardening of the beef slices is prevented, and airflow can penetrate through the beef slices easily for drying the beef slices.

Owner:JISHOU UNIVERSITY

Automatic liquid distribution type zero-release rose essence oil extracting device

ActiveCN106281697ARealize the collectionZero emissionEssential-oils/perfumesThermal insulationEvaporation

The invention discloses an automatic liquid distribution type zero-release rose essence oil extracting device. A spiral coil pipe A and a spiral coil pipe B are immersed in water in a water tank with a thermal-insulation containment; a compressor A, the spiral coil pipe A, a capillary tube A, a refrigeration air conditioner internal unit and relevant pipelines form an A-group heat pump cycle dehumidification system; a heating air conditioner external unit, a heating air conditioner internal unit, a capillary tube B, the spiral coil pipe B and relevant pipelines form a B-group heat pump cycle heating system; the system A is used for realizing the cooling in the thermal-insulation containment and the condensation release of vaporous water and essence oil and storing the heat released during the cooling and the condensation release of the vaporous water and the essence oil into the water tank; the system B is used for realizing the heating in the thermal-insulation containment, gasifying moisture and essence oil in the rose into the thermal-insulation containment and absorbing the heat stored in the water tank by the system A; and the system A and the system B alternately work to realize the evaporation, condensation, discharging of the moisture and essence oil in the rose and store and utilize the heat in the water tank. Compared with the prior art, the automatic liquid distribution type zero-release rose essence oil extracting device has the advantages that the energy consumption is greatly reduced, and the loss of the rose essence oil is almost zero.

Owner:永顺县大丰生态农业开发有限公司

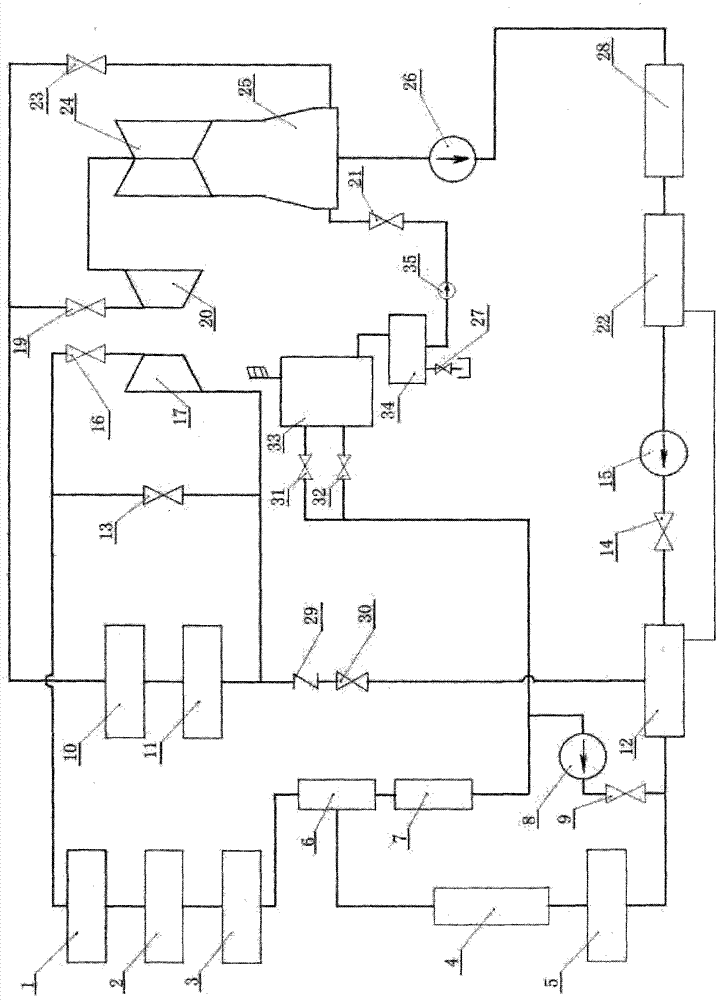

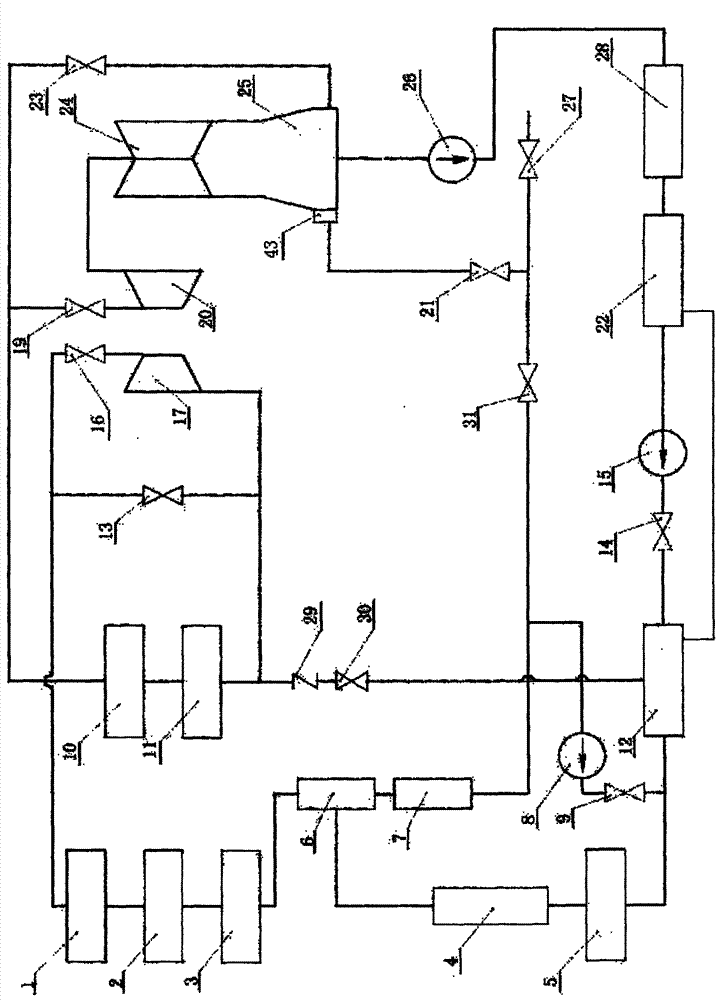

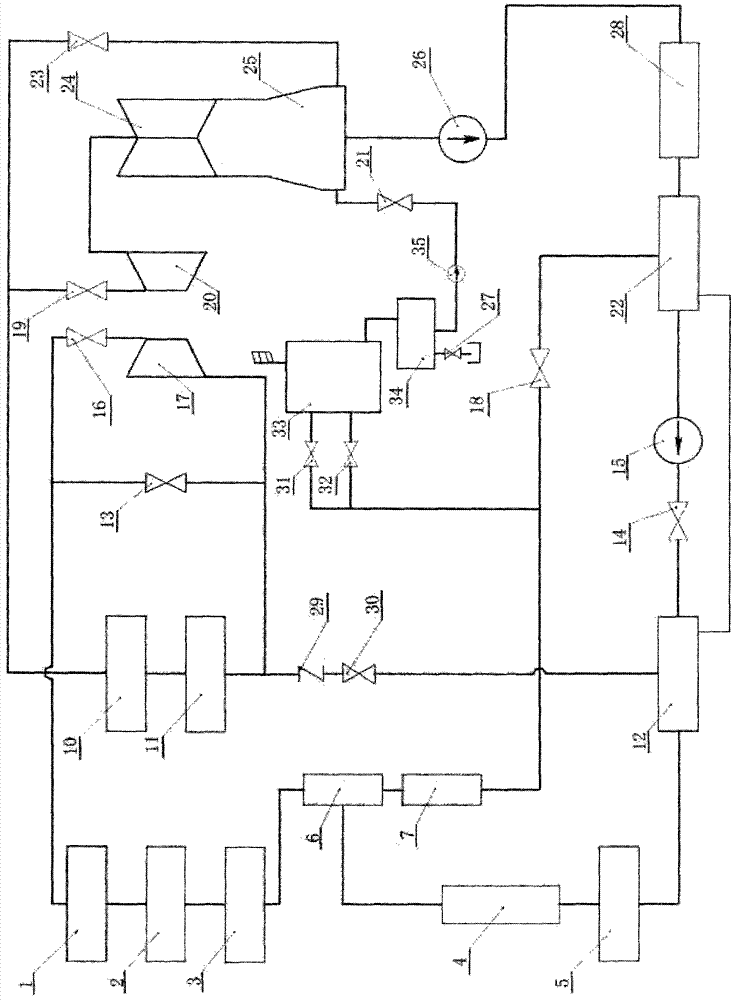

Pump-free direct current furnace starting system capable of recycling working medium and heat comprehensively

ActiveCN102175021BWarm up wellAchieve recyclabilityFeed water supplySteam boilersSpecial designWater circulation

The invention relates to a pump-free direct current furnace starting system capable of recycling a working medium and heat comprehensively, and provides a direct current furnace starting system which is used for a supercritical direct current furnace without a starting furnace water circulation pump at a power station and can recycle the working medium and heat comprehensively. According to the invention, during the starting period of the direct current furnace, three high-pressure heaters at the side of a turbine are utilized as a water heat exchanger, heat is emitted in echelon by the starting of the drainage with high enthalpy, pressure is reduced, thus the enthalpy is reduced to be suitable for the safe recovery by a deaerator; double control logic of the high-pressure heater by a machine set DCS (data conversion system) with special design ensures each high-pressure heater to complete the starting whole process of the direct current furnace and a heat regenerative system working pattern safely and economically under two different working patterns; the working medium and heat can be recycled comprehensively by each starting working condition and starting whole process, and therecycled effect is superior to the direct current furnace starting system with a starting furnace water circulation pump; and the maintaining expense of the infrastructural construction investment and operation can be reduced greatly by the starting furnace-free circulation pump and a subsystem thereof.

Owner:章礼道

A kind of phosphate rock decarburization calcining method

The invention discloses a phosphate rock decarbonization and calcination device, which belongs to the field of phosphate rock decarbonization and calcination, and includes a flue gas heat recovery, a phosphate rock powder preheating section, a phosphate rock powder fluidized calcination decomposition section and a phosphate rock clinker connected in sequence Cooling and heat recovery section, the flue gas heat recovery and phosphate rock powder preheating section includes at least three-stage gas-solid separators connected to each other, the phosphate rock powder fluidized calcination decomposition section is a material dispersion fluidized calcination device, The phosphate rock clinker cooling and heat recovery section includes a connected air cooling device and at least one gas-solid separator; the present invention has a high carbonate decomposition rate, which can greatly improve the phosphorus recovery rate of subsequent processes, And significantly realize the phosphate rock pre-calcination device that saves energy and reduces consumption.

Owner:成都建筑材料工业设计研究院有限公司

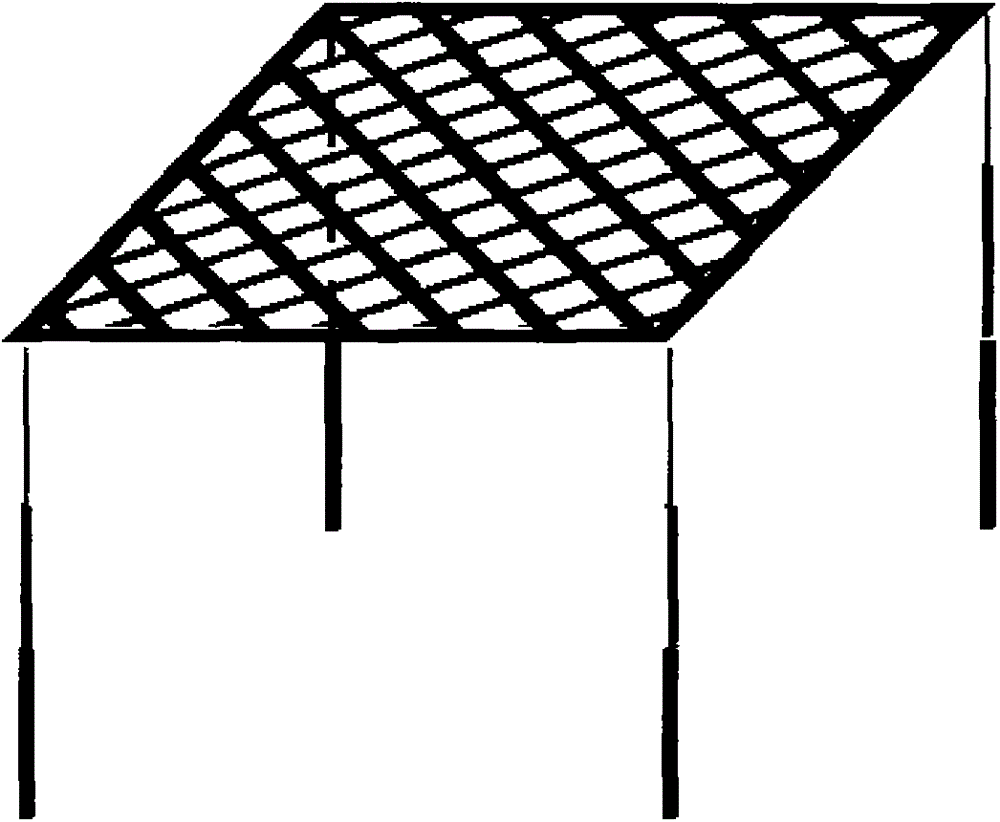

Hot-air drying equipment for dehydrated vegetables

InactiveCN103478861ATake advantage ofIncrease productionFood processingDrying gas arrangementsThermal energyThree stage

The invention belongs to the technical field of dehydrated vegetable production equipment, particularly relates to hot-air drying equipment for dehydrated vegetables, and solves the problem of insufficient energy utilization of conventional hot-air drying equipment of the dehydrated vegetables. The hot-air drying equipment comprises a boiler and hot-air drying ovens, the hot-air drying ovens include a plurality of first hot-air drying ovens and a plurality of second hot-air drying ovens, the boiler is connected with water inlets of the first hot-air drying ovens through a water pipe, water outlets of the first hot-air drying ovens are connected with water inlets of the second hot-air drying ovens, and water outlets of the second hot-air drying ovens are connected with a drain pipe. The heat sources are fully utilized since the heat sources provided by the boiler are utilized in a multistage manner and the hot-air drying ovens are divided into three stages to have the dehydrated vegetables dried.

Owner:SHANXI SHUYAN FOOD

Plastic production device with raw material preheating pipeline

The invention relates to the technical field of plastic processing equipment, and relates to a plastic production device provided with a raw material preheating pipeline. It includes sequentially connected silos, feeding pipelines, weighing machines, mixers, temporary silos, extruders, die surface eager cutting granulators, first cyclone separators, second cyclone separators, vibrating screens and Packaging machine; the feeding pipeline includes a pipeline body, the pipeline body includes a columnar pipeline body, the middle part of the pipeline body is configured with a heating flow channel for entering high-temperature medium in the axial direction, and the inside of the pipeline body is structured around the heating flow channel in the axial direction There is at least one feed channel for feeding materials; the mixer, the first cyclone separator and the second cyclone separator are all provided with waste gas outlets, and all the waste gas outlets are connected with a spray tower. The invention can preferably preheat the transported plastic processing raw materials.

Owner:DEQING BAISHENG PLASTIC CO LTD

Screen body magnetic vibration air conditioning type drying device

InactiveCN106091604AReduce lossZero emissionMechanical apparatusCondensate preventionEvaporationEngineering

The invention discloses a screen body magnetic vibration air conditioning type drying device. A water tank is arranged in a heat insulation enclosure. Water is poured into the water tank to immerse a spiral coil A and a spiral coil B which are located in the water tank. A heat pump circulating dehumidifying system A is formed by a compressor A, the spiral coil A, a capillary tube A, a refrigerating air conditioning internal machine and relevant pipelines. A heat pump circulating heating system B is formed by a heating air conditioning external machine, a heating air conditioning internal machine, a capillary tube B, the spiral coil B and relevant pipelines. Evaporation, condensation and discharge of moisture of materials in the heat insulation enclosure and storage and utilization of heat in the water tank are achieved through alternate working of the system A and the system B. A device used for driving a screen body to conduct differential and impulse type vibration in a magnetic mode is further arranged in the heat insulation enclosure. Compared with an existing gas state dehumidifying drying mode, energy consumption is greatly reduced, and refrigerating and dehumidifying heat zero emission can be achieved; and the screen body is driven to conduct differential and impulse type vibration up and down through alternate magnetic force, material stirring is particularly facilitated, material hardening is avoided, and airflow through drying is promoted.

Owner:湘西银湘农业科技有限责任公司 +1

Plastic production system with raw material preheating pipeline

InactiveCN105757388AEasy to transportEasy to implementThermal insulationPipe heating/coolingCycloneEngineering

The invention relates to the technical field of plastic processing equipment, in particular to a plastic production system with a raw material preheating pipeline.The plastic production system comprises a stock bin, a material conveying pipeline, a material weigher, a material mixer, a temporary stock bin, an extruder, a modular surface hot-cutting granulator, a first cyclone separator, a second cyclone separator, a vibrating screen and a packager which are sequentially connected; the material conveying pipeline comprises a pipeline body, the pipeline body comprises a pipeline main body shaped like a column, the middle of the pipeline main body is provided with a heating runner used for introducing a high-temperature medium in the axial direction, and at least one feeding channel used for introducing materials is formed in the pipeline main body in the axial direction in the mode of surrounding the heating runner.The plastic production system with the raw material preheating pipeline can well preheat the production raw materials.

Owner:DEQING BAISHENG PLASTIC CO LTD

Air-conditioning type drying device

The invention discloses an air-conditioning type drying device. A water tank is arranged in a heat-insulating enclosure, water is injected into the water tank to immerse a spiral coil A and a spiral coil B in the water tank. A compressor A, the spiral coil A, a capillary tube A and a refrigerating air conditioner internal unit and relevant pipes form a heat pump circulating humidification system A. A heating air conditioner external unit, a heating air conditioner internal unit, a capillary tube B and relevant pipes form a heat pump circulating heating system B. The system A achieves temperature reduction in the heat-insulating enclosure and condensation and discharge of vaporous water and stores heat released through temperature reduction and vaporous water condensation. The system B achieves temperature rise in the heat-insulating enclosure and material moisture vaporization to the heat-insulating enclosure and absorbs the heat stored in the water tank by the system A. The system A and the system B alternatively work to achieve evaporation, condensation and discharge of material moisture in the heat-insulating enclosure and storage and utilization of the heat in the water tank. Compared with an existing gaseous humidification and drying mode, the energy consumption is greatly reduced, and refrigeration, dehumidification and zero heat discharge can be achieved.

Owner:湘西银湘农业科技有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com