Low-noise plastic production device capable of achieving efficient feeding

A production device and feeding technology, applied in the direction of coating, etc., can solve problems such as affecting production efficiency, lack of conveying system, inability to extract or convey well, etc., to achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

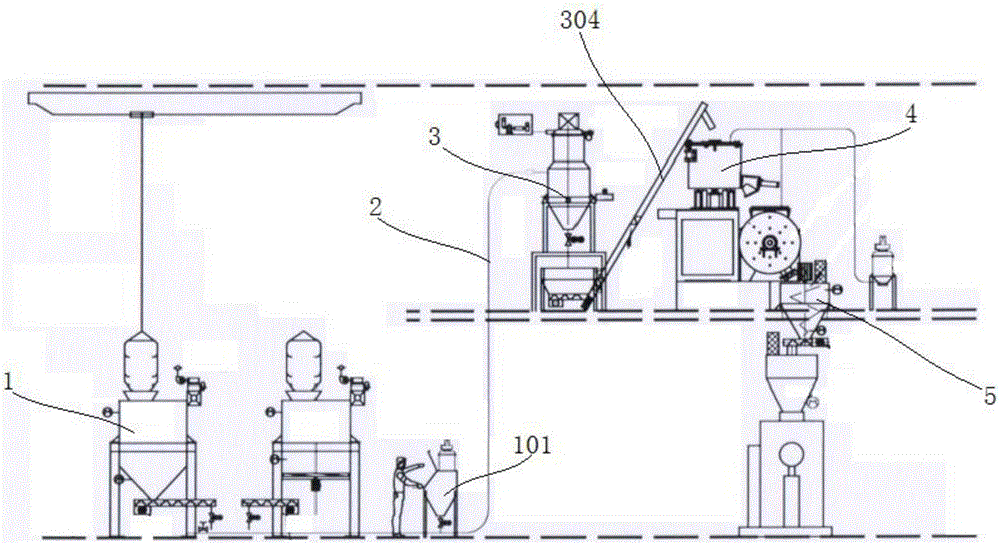

[0073] This embodiment provides a plastic production system, which includes a silo 1, a small material feeding silo 101, a feeding system and a processing system, which can preferably recycle the heat generated in the production process, have low noise and can The waste gas is preferably treated.

[0074] like figure 1 As shown, the feeding system includes a weighing machine 3, a mixing machine 4 and a temporary silo 5 connected in sequence, and the silo 1 and the small material feeding bin 101 are connected to the weighing machine 3 through the feeding pipeline 2, and the weighing machine 3 and the mixer 4 are provided with a screw feeder 304.

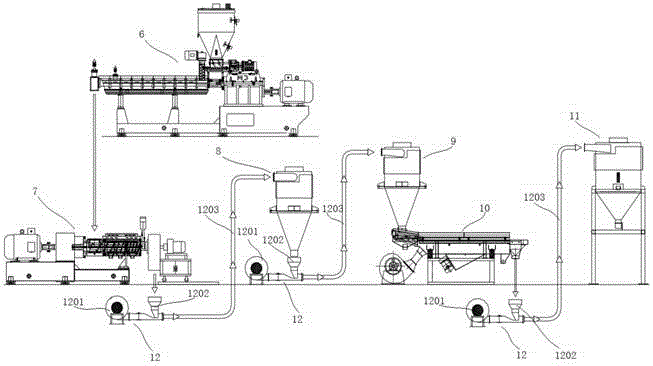

[0075] like figure 2 As shown, the processing system includes an extruder 6, a die face hot cutting granulator 7, a first cyclone separator 8, a second cyclone separator 9, a vibrating screen 10 and a packaging machine 11 connected in sequence, and the extruder 6 is connected with a temporary Silo 5 is connected. A wind power con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com