Laser welding and testing integrated method for condensation pipe

A technology of laser welding and condensation pipes, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that the online automatic test of weld quality has not been realized, it is difficult to realize the automation of welding process, and it is difficult to ensure the sealing of condensation pipes, etc. , to achieve the effect of realizing online testing, reducing temperature inhomogeneity and ensuring metallurgical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

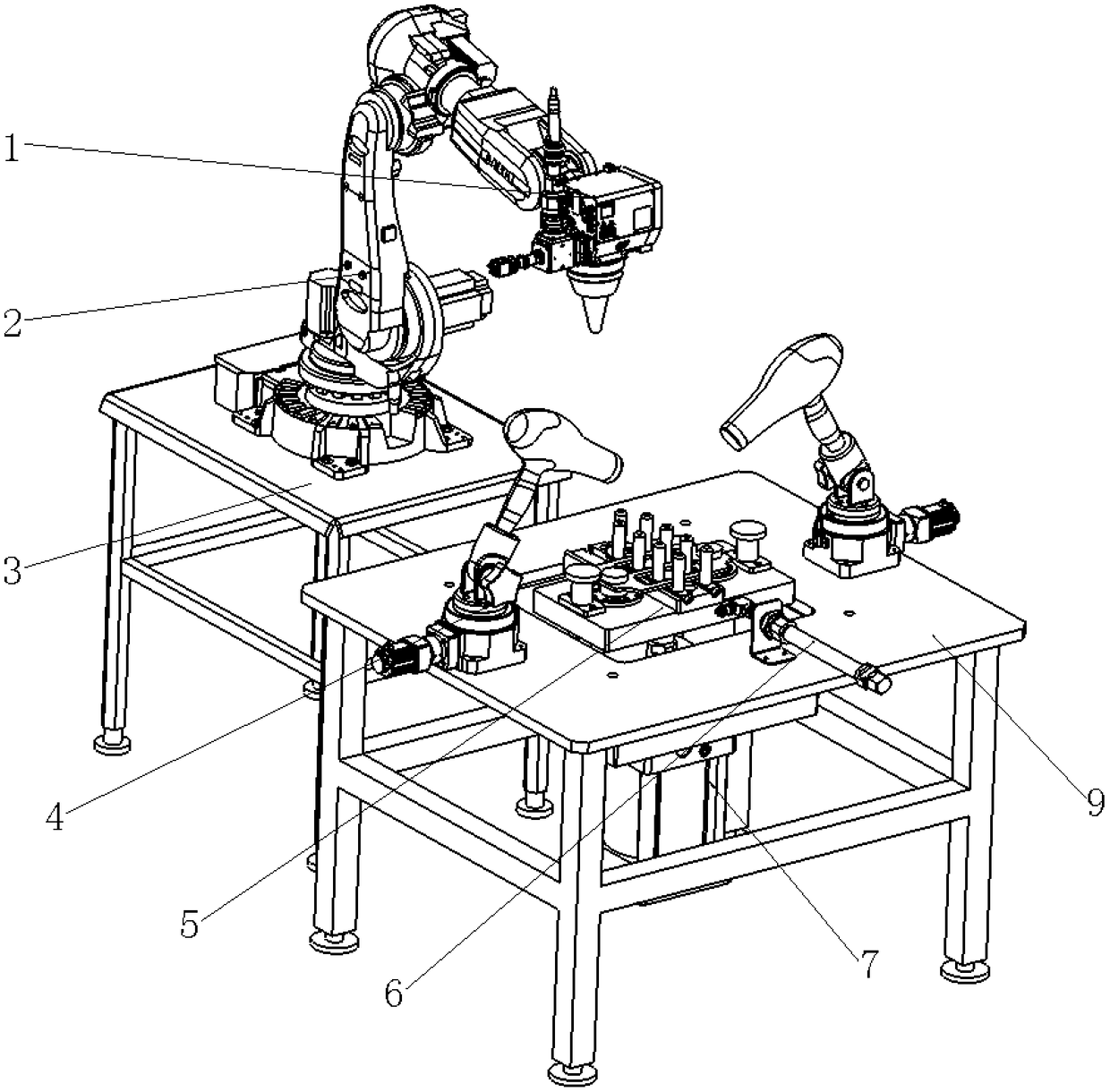

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

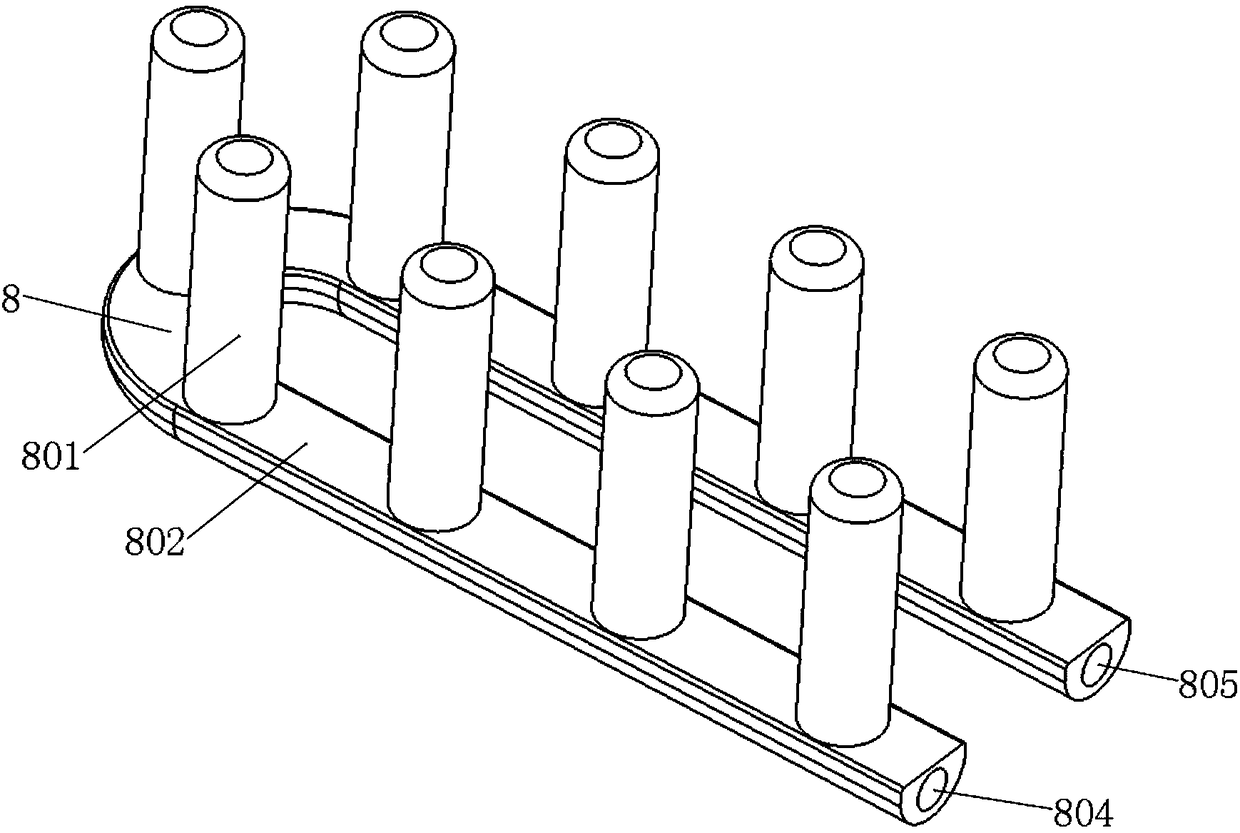

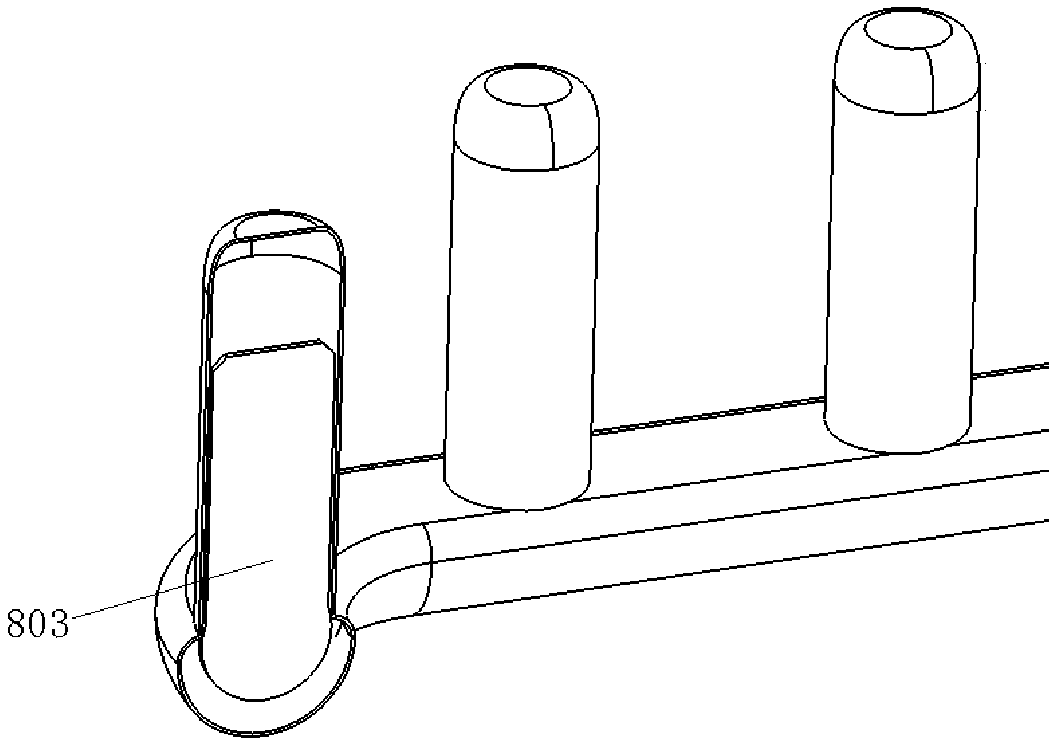

[0039] Such as Figure 1-13 As shown, the condenser tube 8 of the present invention is composed of a U-shaped tube 802 and a plurality of column tubes 801; the column tube 801 is a cylindrical structure with a hollow inside, one end closed, and the other end open, and the wall thickness of the cylinder is 0.2 mm ~ 2mm, a separator 803 is arranged in the middle of the column tube 801, thereby dividing the internal space of the column tube 801 into two parts; mm~0.05mm, that is, when the length direction of the separator 803 is assembled along the axial direction of the column tube 801 (that is, the width direction of the separator 803 is parallel to the radial direction of the column tube 801), the two sides of the length direction are aligned with the column tube 801 The wall of the tube is a tight interference fit; there is a gap for gas or li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com