Carrier particle with porous structure and its preparation method and application

A technology of carrier particles and porous structure, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc. Accuracy and other issues, to achieve the effect of improving atomization and transfer performance, simple operation, and good controllability of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

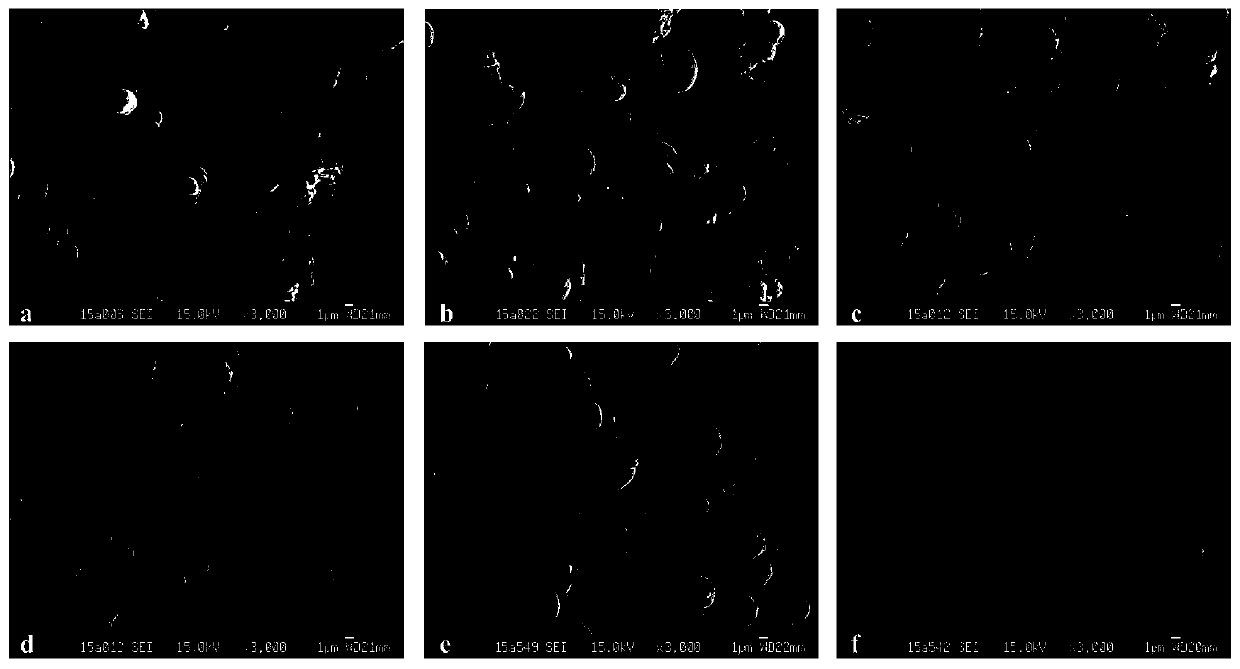

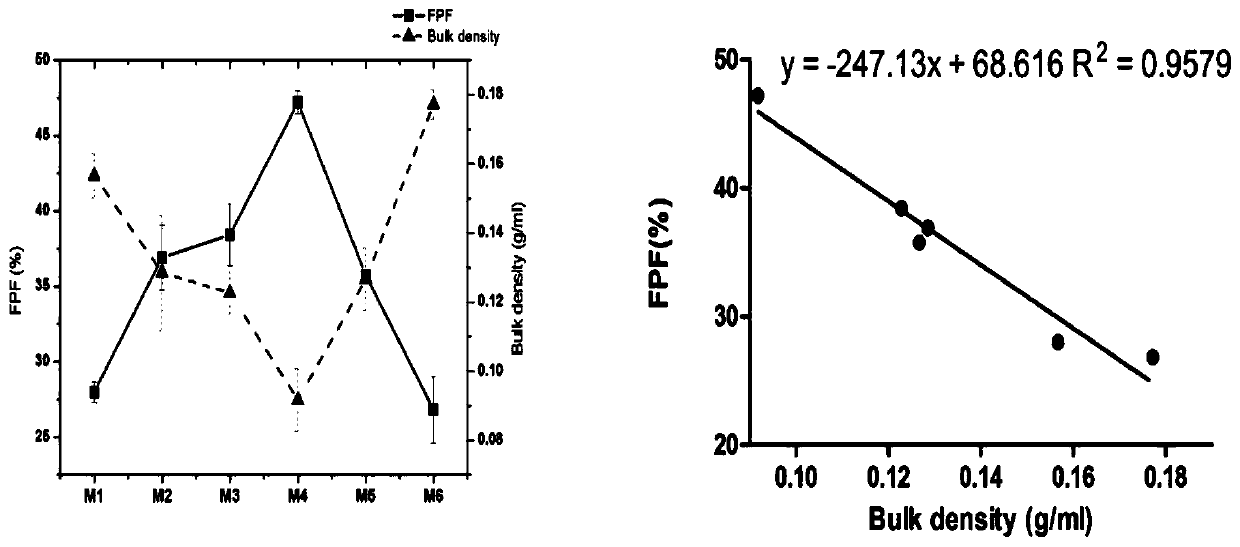

[0056] Dissolve mannitol and ammonium carbonate in different mass ratios (1:1, 2:1, 3:1, 4:1, 5:1, 7:1) or separate mannitol in water, and prepare a concentration of 25mg respectively / ml (the total concentration of mannitol and ammonium carbonate), and then adopt a spray dryer to spray dry the above solution to prepare carrier particles. The conditions of spray drying are as follows: the inlet air temperature is 130°C, and the outlet air temperature is 75°C. The liquid rate is 10ml / min, the nozzle diameter is 0.71mm, the atomization pressure is 90Kpa, and the air flow rate is 0.60m 3 / h. The mannitol carrier particles obtained under these conditions were evaluated or characterized as follows.

[0057] (1) Density measurement, the specific method is: take an appropriate amount of carrier mg and place it in a 1ml precision syringe, and record the initial volume V of the carrier. 0 , then the bulk density of the carrier is ρ b =m / V 0 ;Tap the syringe until the volume of the ...

Embodiment 2

[0069] Dissolve small molecule sugar alcohols (lactose, mannitol or trehalose) and ammonium carbonate in water at a mass ratio of 3:1, and prepare solutions with a concentration of 25 mg / ml (the total concentration of small molecule sugar alcohols and ammonium carbonate) , and then use a spray dryer to spray-dry the above solution to prepare porous carrier particles. The spray-drying conditions are as follows: the inlet air temperature is 130°C, the outlet air temperature is 75°C, the pump liquid rate is 10ml / min, and the nozzle diameter is 0.71mm, atomization pressure is 90Kpa, air flow is 0.60m 3 / h.

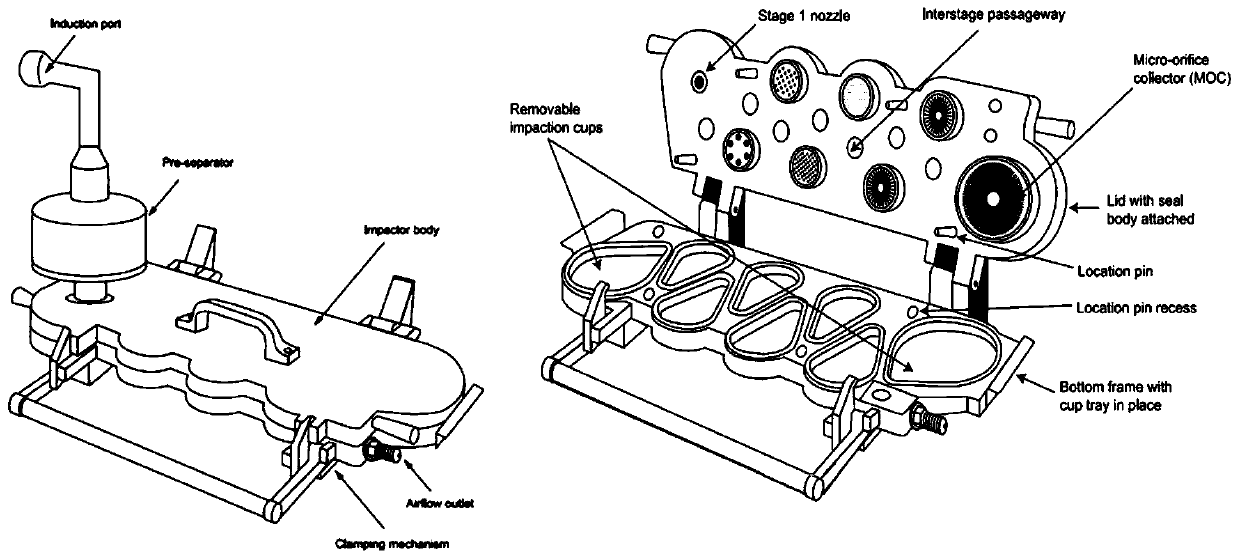

[0070]Mix the spray-dried porous carrier particles with micronized ciprofloxacin hydrochloride drug particles and budesonide drug particles at a mass ratio of 30:1, and pack them into No. 3 capsules (10±0.5mg / capsule) , that is, ciprofloxacin hydrochloride dry powder inhaler or budesonide dry powder inhaler, and a new generation of pharmaceutical impactor (NGI) was used to ev...

Embodiment 3

[0079] Dissolve mannitol and porogen (ammonium carbonate or ammonium bicarbonate) in water at a mass ratio of 3:1, and prepare solutions with a concentration of 25 mg / ml (the total concentration of mannitol and porogen) respectively, and then use a spray dryer to The above solution is spray-dried to prepare carrier particles with a porous structure. The spray-drying conditions are as follows: the inlet air temperature is 130°C, the outlet air temperature is 75°C, the pump liquid rate is 10ml / min, the nozzle diameter is 0.71mm, and the atomization pressure 90Kpa, airflow 0.60m 3 / h. See Table 4 for the median diameter, bulk density and bulk density of the carrier particles with porous structure after spray drying. The results show that: the carrier particles with porous structure prepared by using ammonium carbonate as thermal decomposition type porogen have little difference between the median particle diameter and the median particle diameter when ammonium bicarbonate is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com