Assembled structure of brake release knob

A button and structure technology, which is applied in the field of brake release button assembly structure, can solve the problems of button breakage, difficulty in confirming the brake release button, and failure to obtain the specified installation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

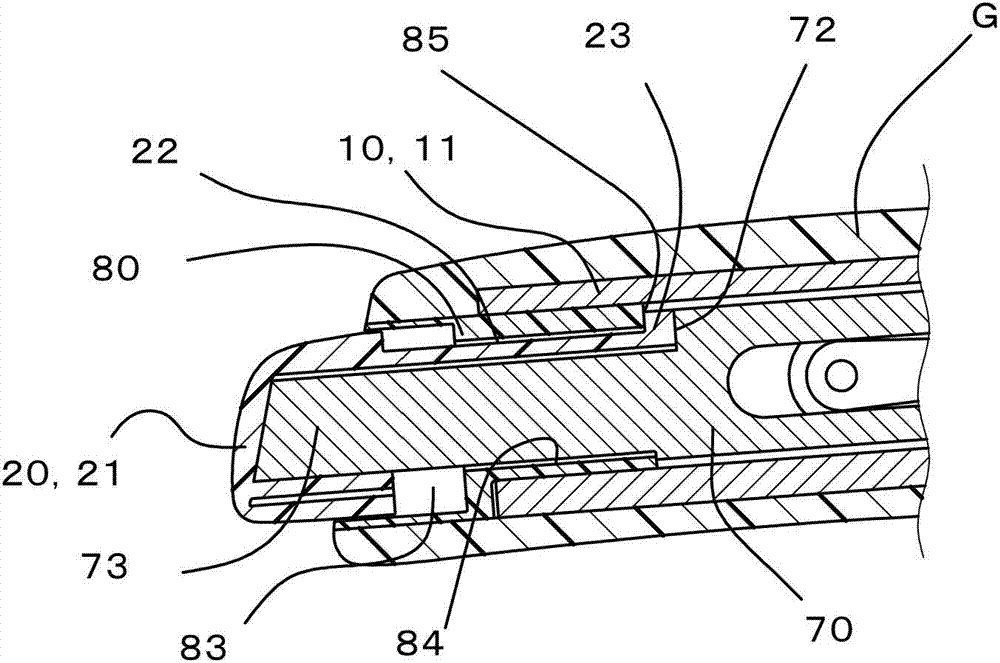

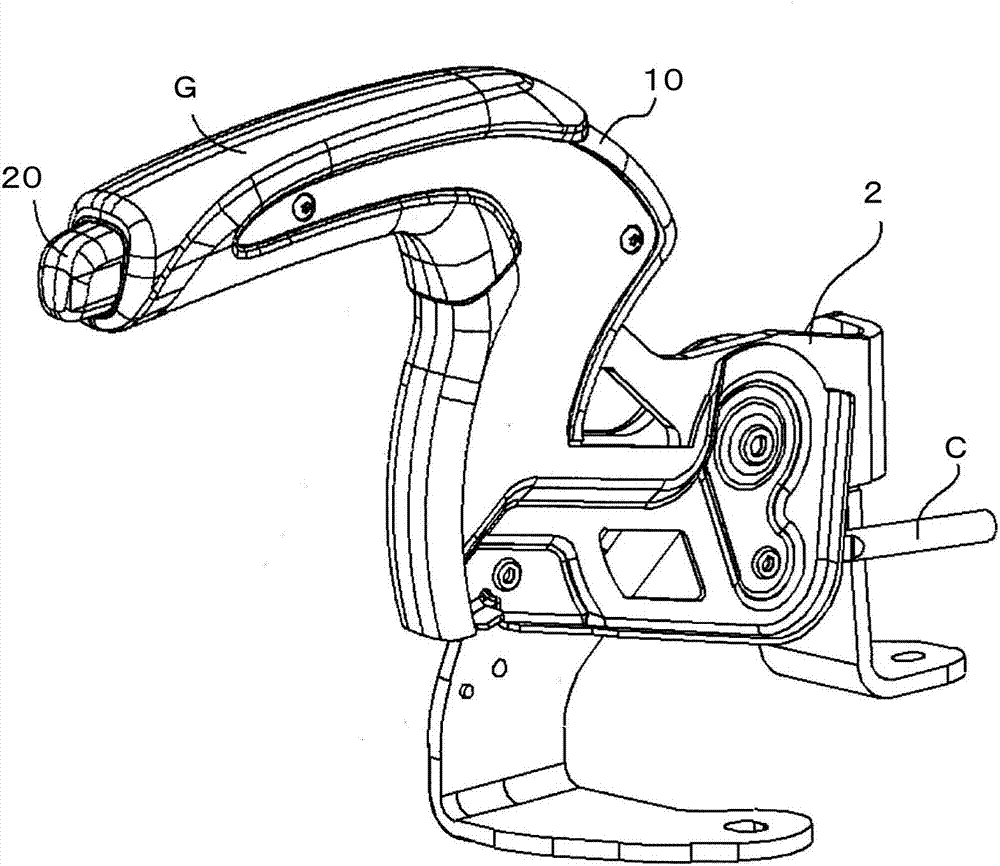

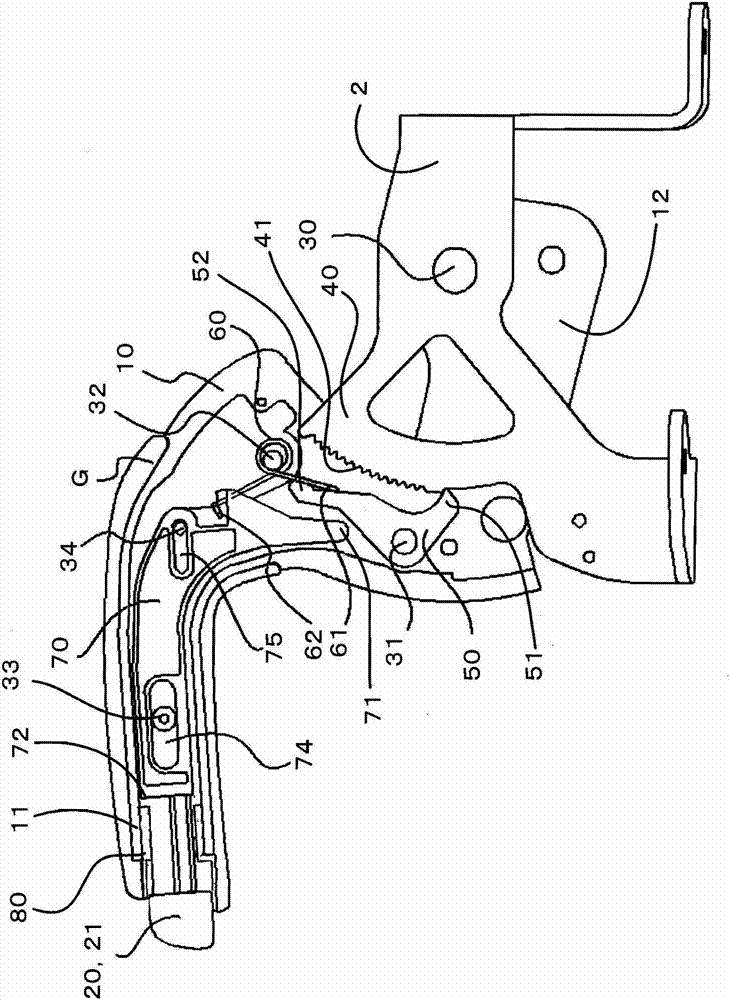

[0032] Hereinafter, a preferred embodiment of the present invention will be described with reference to the drawings.

[0033] Each drawing shows an embodiment of the present invention.

[0034] Such as Figures 1 to 3 As shown, in terms of the parking brake 1 of the present invention, the brake lever 10 is pivotally supported on the base member 2 fixed on the side of the vehicle body in a manner that can be pulled up and down. The moving lever 10 transmits force to the brake part via a cable not shown to generate a braking force. When releasing the braking state of the brake, the brake release button 20 arranged on the front end portion 11 of the brake lever is pressed. Insert the brake lever 10 into the brake lever 10 while laying down the brake lever 10. For the brake lever 10 , in order to improve the feeling of use during operation, the handle G is used to cover the part that is held by hand during operation.

[0035] A base end portion 12 of the brake lever 10 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com