Glass substrate position correcting device and method

A glass substrate and calibration device technology, applied in conveyor control devices, transportation and packaging, furnaces, etc., can solve the problems of glass substrate damage, product yield decline, affecting production efficiency, etc., to prevent damage and reduce defective rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0040] The invention provides a glass substrate correction device used on the roller transmission path, which is used for

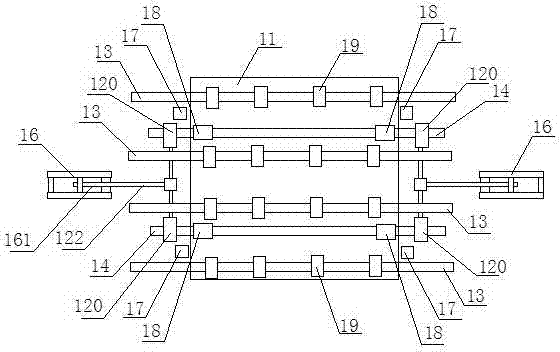

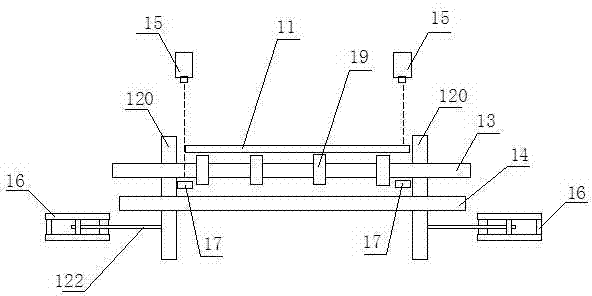

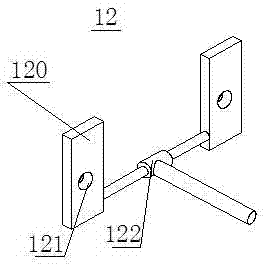

[0041] Such as Figure 1 to Figure 3 As shown, a glass substrate position correction device of the present invention is shown, the glass substrate position correction device is used for correcting the position of the glass substrate being transported, especially for the correction of the glass substrate at the junction of the roller transport. It includes:

[0042] Roller sets 19 arranged on multiple rollers 13 can be used to transport glass substrates 11 through the rotation of said roller sets 19 in the same direction, wherein a plurality of rollers 13 are arranged at intervals, and the upper surface of said roller sets 19 Being on the same plane, the glass substrate 11 moves on the plane;

[0043] At least two guide shafts 14,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com