A hanger with adjustable leverage ratio

An adjustable and leverage ratio technology, applied in the field of hangers, can solve the problems of plastically deformed bent shafts, scrapped bent shafts, scrapped, etc., and achieve the effect of reducing stress values and avoiding additional stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

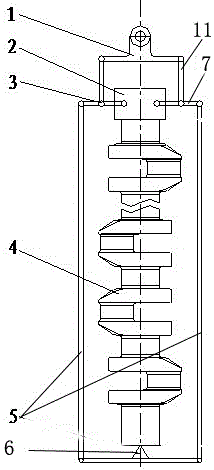

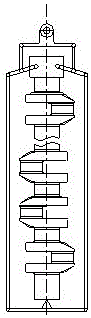

[0015] Example: such as figure 1 As shown, a kind of leverage ratio adjustable hanger includes a hanger 1, a hook 2, a tray frame 5, a tray 6 and two adjustable rods 7, and the tray frame 5 is composed of two vertical bars parallel to each other, each The lower ends of the vertical rods are respectively fixedly connected to the tray 6, and the upper ends are respectively connected to the ends of an adjustable rod 7. The two adjustable rods 7 are provided with a number of suspension holes 3 and the other ends are symmetrically connected to each other. On the hook 2, the lower part of the hanger 1 is two hanging rods 11, and the lower end of each hanging rod 11 is connected to one of the hanging holes 3 on an adjustable rod 7 through a pin rotation.

[0016] The top of the hanger 1 is provided with a hanging hole.

[0017] When the bent shaft 4 is hung on the present invention, since the lever structure where the hanging hole 3 is located distributes the gravity in proportion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com