A multi-directional restraint device for ballasted track bed

A restraining device and track technology, applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of insufficient structural constraints of the ballast bed, insufficient longitudinal and lateral resistance, etc., to reduce the number of maintenance, improve the average force, increase the area and effect of depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

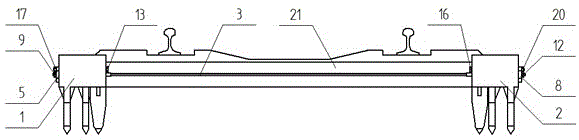

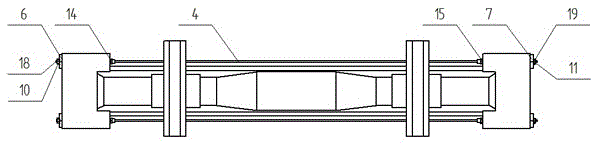

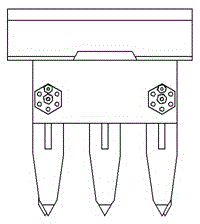

[0040] Example 1: Such as Figure 1-9 As shown, a multi-directional restraint device for a ballasted track bed includes a reinforced concrete block on the left side of the line 1, a reinforced concrete block on the right side of the line 2, a screw rod I3, a screw rod II4, an internal thread fastening sleeve I5, and an internal thread fastening sleeve Cylinder Ⅱ6, internal thread fastening sleeve Ⅲ7, internal thread fastening sleeve Ⅳ8, lock nut Ⅰ9, lock nut Ⅱ10, lock nut Ⅲ11, lock nut Ⅳ12, stop bolt Ⅰ13, stop bolt Ⅱ14, stop Moving bolt Ⅲ15, stop bolt Ⅳ16, nut Ⅰ17, nut Ⅱ18, nut Ⅲ19, nut Ⅳ20, sleeper 21;

[0041] The reinforced concrete block 1 on the left side of the line is placed on the left side of the sleeper 21, and the reinforced concrete block 2 on the right side of the line is placed on the right side of the sleeper 21;

[0042] Screw Ⅰ3 passes through the left reinforced concrete block 1, the right reinforced concrete block 2 of the line and two large holes on the front s...

Embodiment 2

[0063] Example 2: Such as Figure 1-9 As shown, a multi-directional restraint device for a ballasted track bed includes a reinforced concrete block on the left side of the line 1, a reinforced concrete block on the right side of the line 2, a screw rod I3, a screw rod II4, an internal thread fastening sleeve I5, and an internal thread fastening sleeve Cylinder Ⅱ6, internal thread fastening sleeve Ⅲ7, internal thread fastening sleeve Ⅳ8, lock nut Ⅰ9, lock nut Ⅱ10, lock nut Ⅲ11, lock nut Ⅳ12, stop bolt Ⅰ13, stop bolt Ⅱ14, stop Moving bolt Ⅲ15, stop bolt Ⅳ16, nut Ⅰ17, nut Ⅱ18, nut Ⅲ19, nut Ⅳ20, sleeper 21;

[0064] The reinforced concrete block 1 on the left side of the line is placed on the left side of the sleeper 21, and the reinforced concrete block 2 on the right side of the line is placed on the right side of the sleeper 21;

[0065] Screw Ⅰ3 passes through the left reinforced concrete block 1, the right reinforced concrete block 2 of the line and two large holes on the front s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com