Textile fabric magnetization dyeing and finishing device

A technology of textile fabrics and magnetizers, which is applied in the processing of textile materials, liquid/gas/steam textile materials, textiles and papermaking, etc. It can solve the problem of destroying association water molecule groups, unsatisfactory magnetization effects, and poor magnetization effects. Good and other problems, to achieve greater water solubility, save dyes, and improve the effect of magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below through specific embodiments.

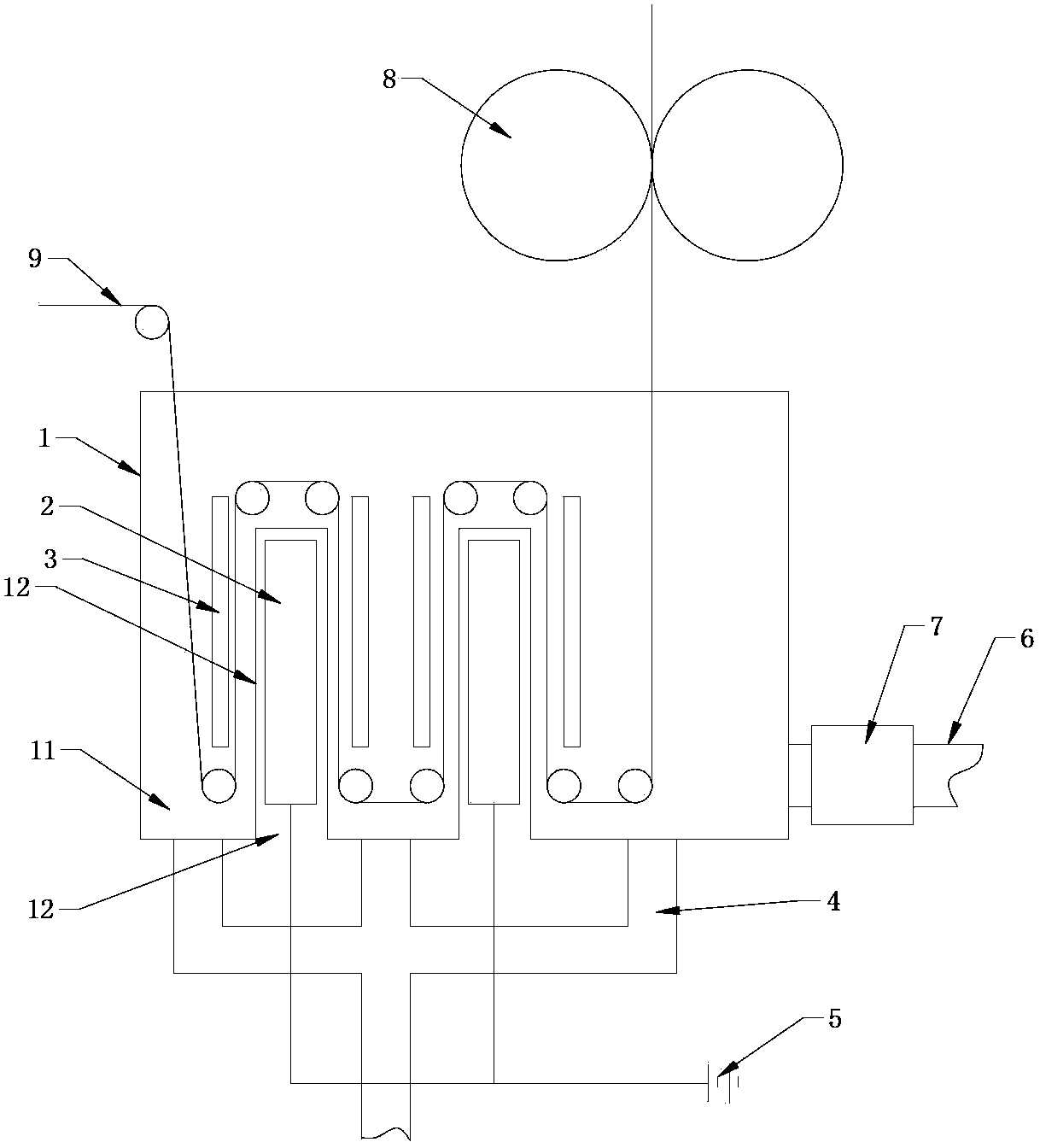

[0014] Such as figure 1 As shown, a textile fabric magnetized printing and dyeing device includes a printing and dyeing tank 1 provided with an inlet. The bottom of the printing and dyeing tank 1 is recessed to form a number of strip-shaped protrusions. From the inside of the printing and dyeing tank 1, these strips The printing and dyeing tank 1 is divided into several printing and dyeing cavities connected at the upper end by the shaped protrusions. When viewed from the bottom of the printing and dyeing tank 1, a number of concave cavities are formed on the bottom. The printing and dyeing tank 1 is provided with several guide rollers. And several guide rollers pass through the printing and dyeing chamber in turn, and then lead out, each printing and dyeing chamber is fixedly installed with a soft magnetic material plate 3, and an electromagnet 2 is provided in the concave cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com