Blade top air injection stability controller for axial flow compression system

A technology of stability control and blade tip injection, which is applied to jet propulsion devices, machines/engines, etc., and can solve problems such as short time and difficult control systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

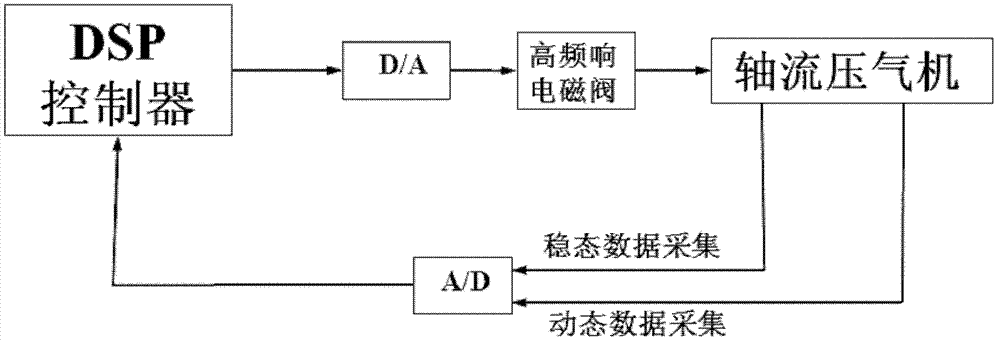

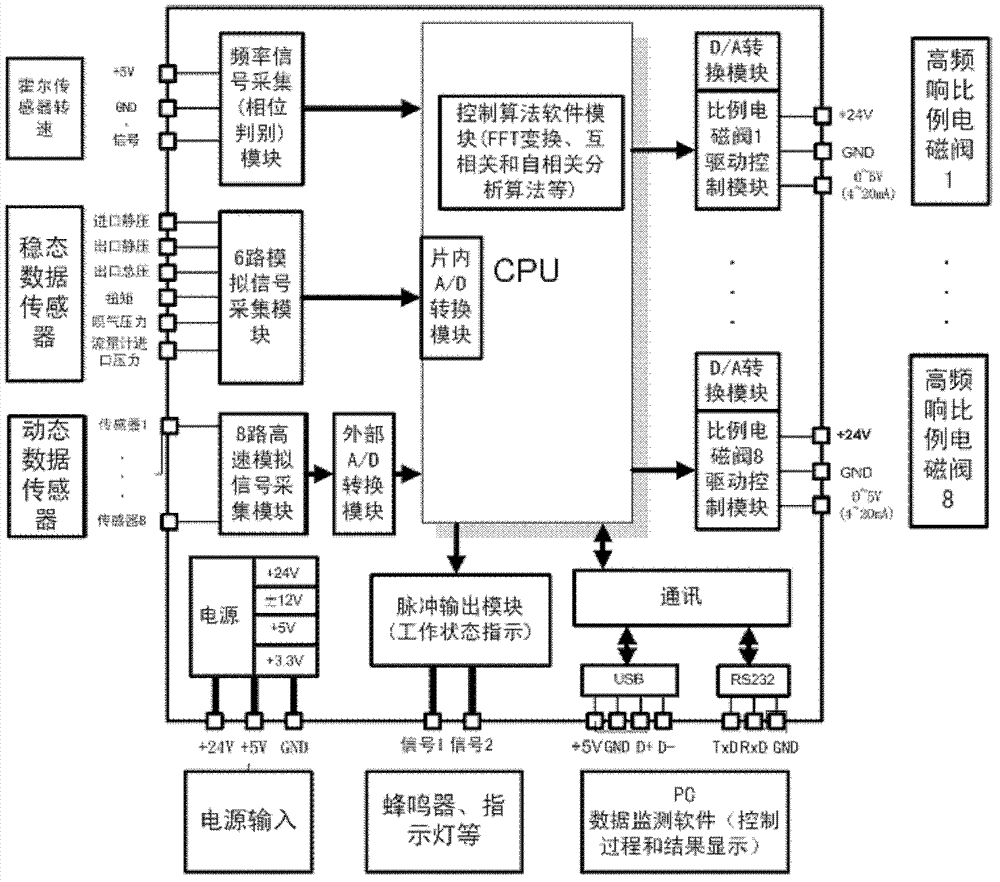

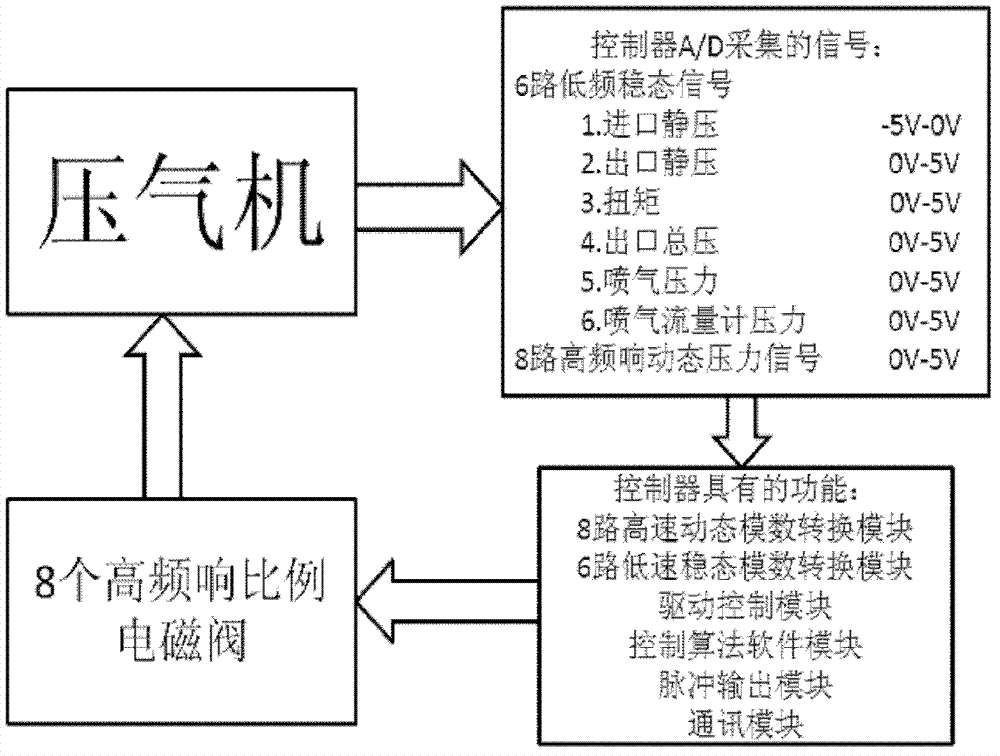

[0043] A controller of the present invention for blade tip jet stability of an axial flow compression system, comprising a processor, eight-way high-speed analog signal acquisition module, six-way analog signal acquisition module, frequency signal acquisition module, communication module, pulse output module, eight-way High-response proportional solenoid valve drive module and power module; multiple steady-state pressure sensors are evenly distributed on the inlet and outlet walls of the axial flow compression system, and multiple dynamic pressure sensors are evenly distributed on the wall circumference of the casing wall on the top of the moving blade of the compression system The sensor, the steady-state pressure sensor is electrically connected to the six-way analog signal acquisition module, and the dynamic pressure sensor is electrically connected to the eight-way high-speed analog signal acquisition module. The two data acquisition modules are controlled by the on-chip A / D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com