Lamp panel technology of LED (Light Emitting Diode) lamp

A technology for LED lamps and light boards, which is applied in electrical components, electric solid state devices, circuits, etc., can solve problems such as the increase in the volume of light boards and the problems of quality control in the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

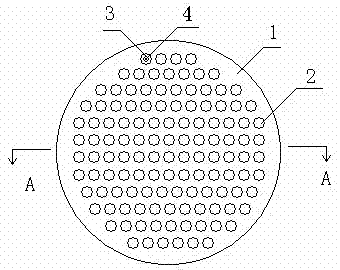

[0016] Such as figure 1 As shown, a lamp panel and process of an LED lamp, including: insulating material and metal wires, the metal wires are evenly distributed in a circular body or a square body formed by the insulating material and formed.

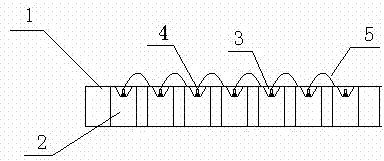

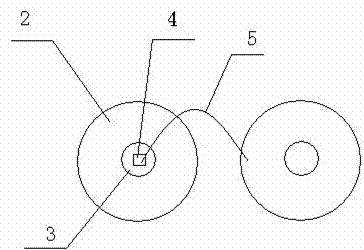

[0017] Such as figure 2 and image 3 As shown, the circular body or square body is cut into an insulating substrate 1, and the metal wires in the insulating substrate 1 are segmented to form a heat dissipation conductor 2. The center of the heat dissipation conductor 2 is stamped to form an LED lamp cup 3, and an electrode of the wafer 4 is passed through a conductive glue. Fixed in the lamp cup 3, the other electrode of the wafer 4 is connected to the second wafer through the bonding wire 5, and the surface of the lamp board on which the LED wafer is placed is sealed with a transparent resin or blue-white light process.

[0018] The metal wires are distributed at intervals of the insulating material, and the interval is between 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com