A soft pack lithium-ion battery module

A lithium-ion battery, ion battery technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of complex heat dissipation structure, high manufacturing cost, unfavorable battery life, etc., and achieve high energy density and compact structure. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

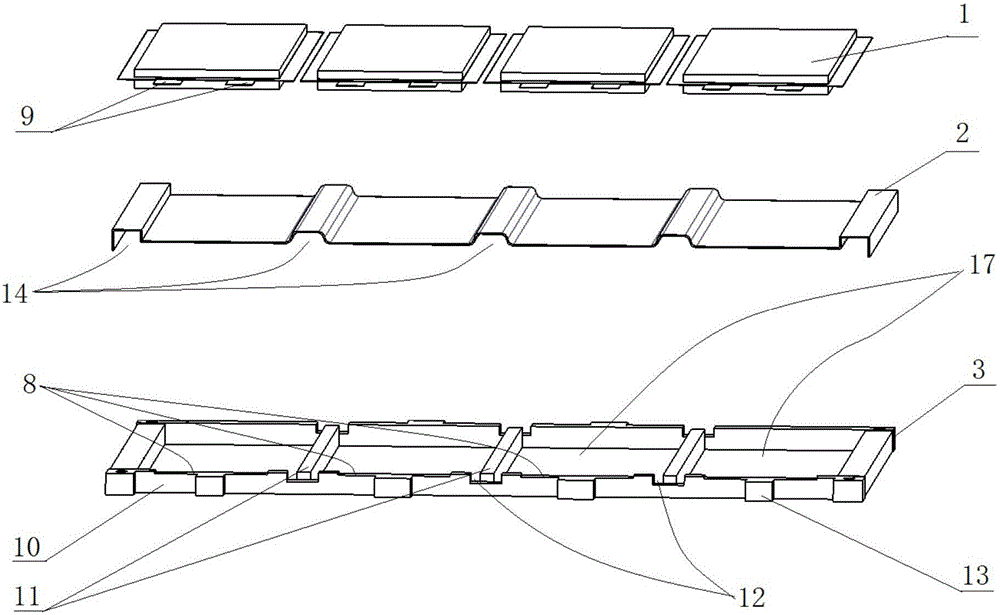

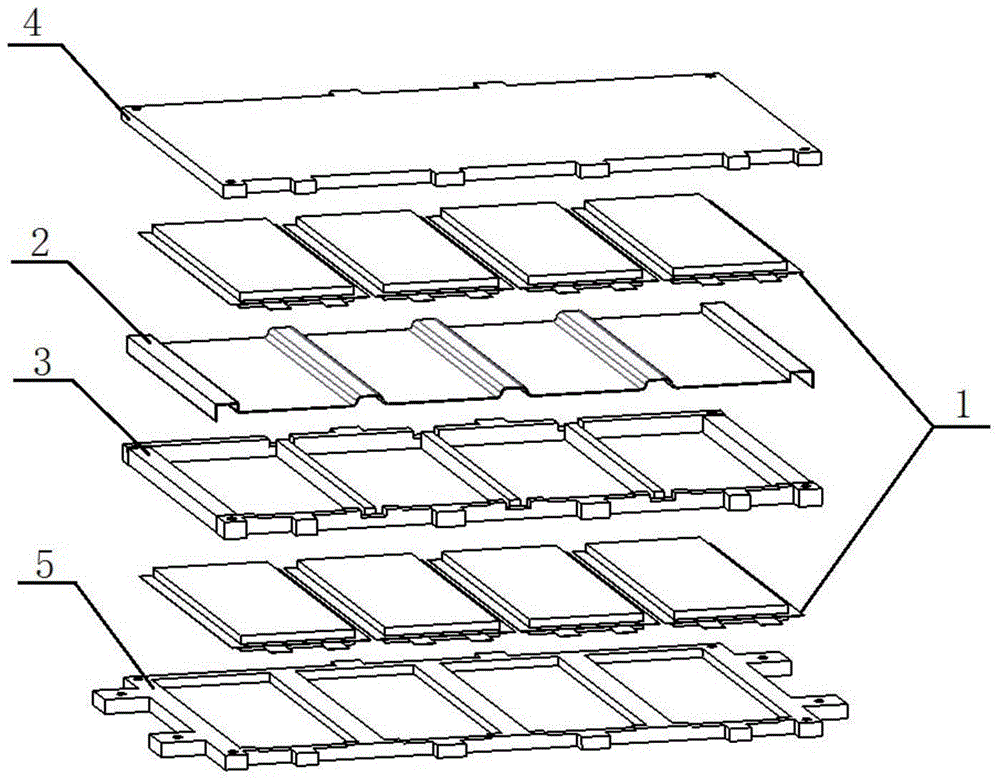

[0042] See attached figure 1 , 2 , 3, 4, 5, 6, a soft pack lithium ion battery module of the present invention, the module includes a soft pack lithium ion battery layer unit, a bottom plate 5, an upper cover 4, and fastening bolts; the soft pack lithium ion battery The layer unit includes a soft-packed lithium-ion battery 1, a frame 3, and a heat dissipation plate 2. The frame 3 is a rectangular structure composed of four rectangular cavities 17. The heat dissipation plate 2 is provided with the same shape and number as the frame 3. Rectangular cavity 17 has the same number of pits, the heat dissipation plate 2 is clamped in the frame 3, and the pits on the heat dissipation plate 2 sink into the rectangular cavity 17 of the frame 3; the soft pack lithium ion battery 1 is set In the pit of the heat dissipation plate 2, a soft-packed lithium-ion battery layer unit is formed as a whole;

[0043] Four soft-pack lithium-ion battery layer units are stacked along the thickness dir...

Embodiment 2

[0056] See attached Figure 7 , the 4×20 module prepared by the present invention constitutes a 72V40Ah soft-pack lithium-ion battery module;

[0057] The difference between Embodiment 2 and Embodiment 1 is that the soft-packed lithium-ion battery module of this embodiment is composed of 20 layers of soft-packed lithium-ion battery layer units, and there are 4 soft-packed lithium-ion battery layer units in each layer. For lithium-ion batteries, every four layers of soft-packed lithium-ion battery layer units are connected in series through the end conductive sheet 6 and the middle conductive sheet 7 to form a battery layer unit group. There are 5 layer unit groups stacked. The terminal conductive sheet 6a is connected in series to finally form a 72V40Ah soft-pack lithium-ion battery module;

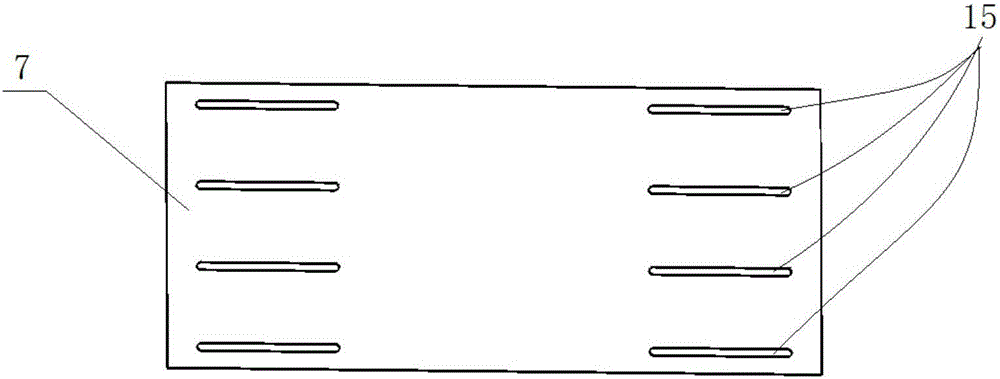

[0058] The middle conductive sheet 7 is rectangular, on which two groups of through grooves are symmetrically distributed along the rectangular axis, and each group of through grooves ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com