Conjoined frame

A frame, conjoined technology, applied in the direction of electrical components, electrical switches, coupling devices, etc., can solve the problems of weak structure, complex structure, difficult to assemble, etc., and achieve the effect of stable and reliable structure, simple structure and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

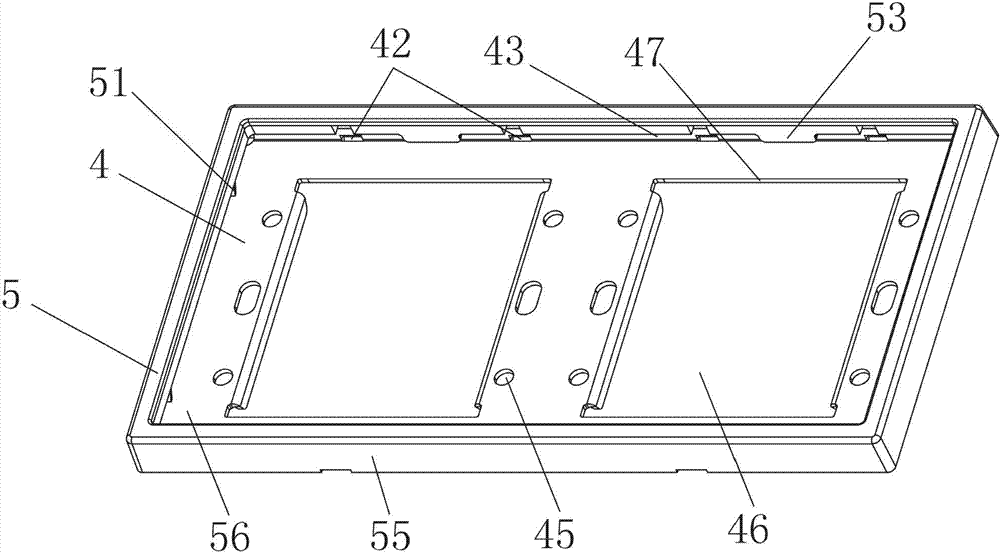

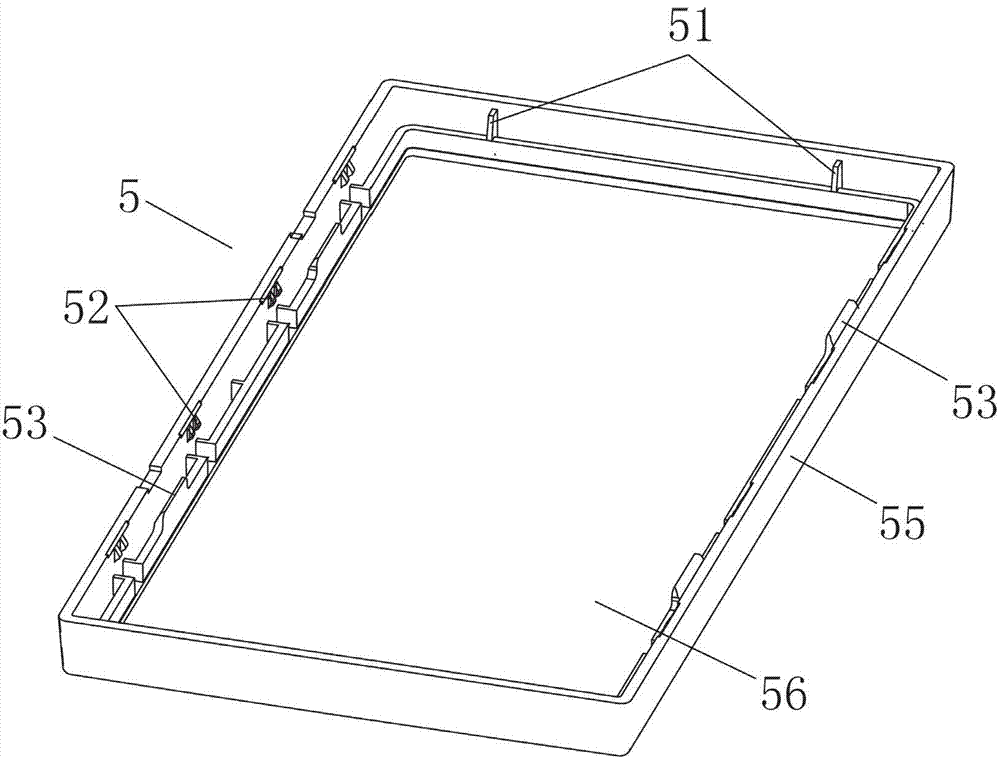

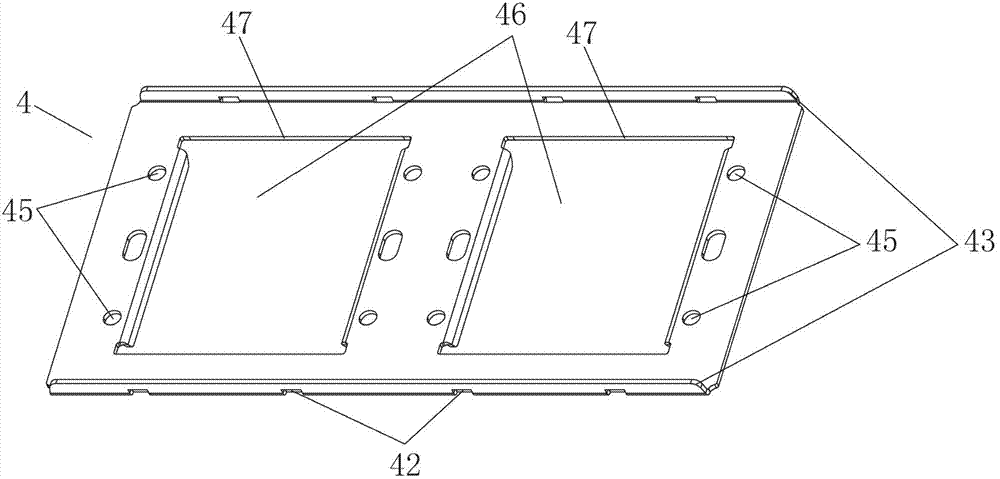

[0029] See Figure 1 ~ Figure 3 As shown, the conjoined frame of the present invention includes an outer frame 5 and an inner panel 4, the outer frame 5 has a central through hole 56 and surrounding sides 55 around the central through hole 56, and the inner panel 4 has spaced At least one through hole 46 , the inner panel 4 snaps into the peripheral side 55 , and the through hole 46 is exposed through the central through hole 56 .

[0030] Any suitable structure can be adopted for the clamping of the inner panel 4 in the surrounding side 55, please refer to Figure 1 ~ Figure 3 As shown, in a specific embodiment of the present invention, claws 52 are provided on the inner sides of the surrounding sides 55, and buckles 42 are provided on the side of the inner panel 4, and the claws 52 snap into the buckles 42. .

[0031] Or, it can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com