a wire stripper

A wire stripper and cable technology, which is applied in the direction of dismantling/armored cable equipment, etc., can solve the problems that the insulation sheath of large-diameter cables cannot be stripped, the metal conductor in the cable is easy to be cut, and the stripping time is long. , to achieve the effect of simplifying stripping work, avoiding hand cuts, and fast stripping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following specific implementation manners, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

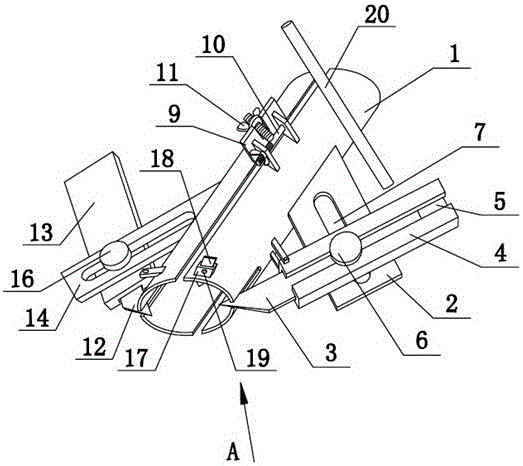

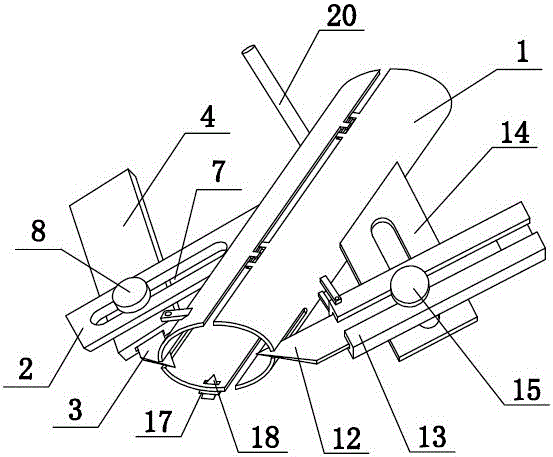

[0026] Wire strippers arranged with 2 sets of blades, such as figure 1 and figure 2 As shown, it includes a cable sleeve 1, a knife holder 2 and a blade 3, the inner diameter of the cable sleeve 1 matches the outer diameter of the cable, and the blade 3 is installed on the cable sleeve 1 through the knife holder 2 Above, the cable sleeve 1 corresponding to the blade 3 is provided with a long slot, and the tip of the blade 3 passes through the slot and enters the cavity of the cable sleeve 1 .

[0027] A knife housing 4 is also arranged between the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com