Flywheel system with a variable speed drive

A driving wheel and driver technology, applied in flywheels, transmissions, electric components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

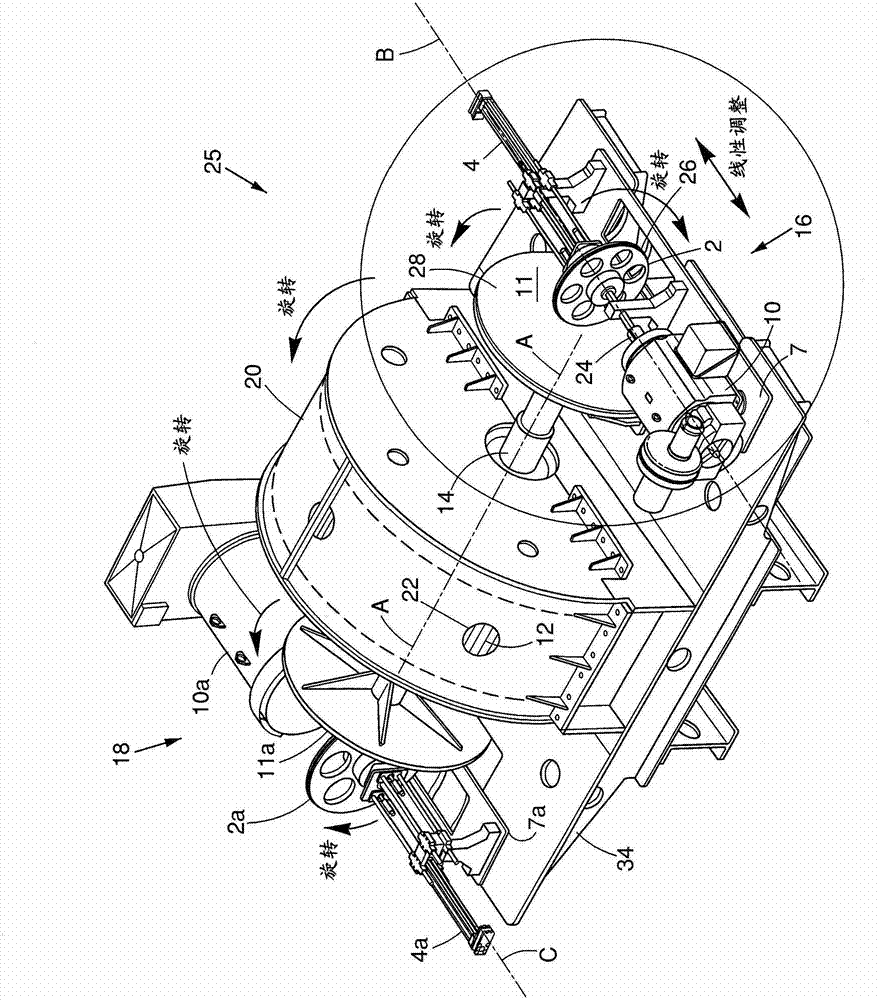

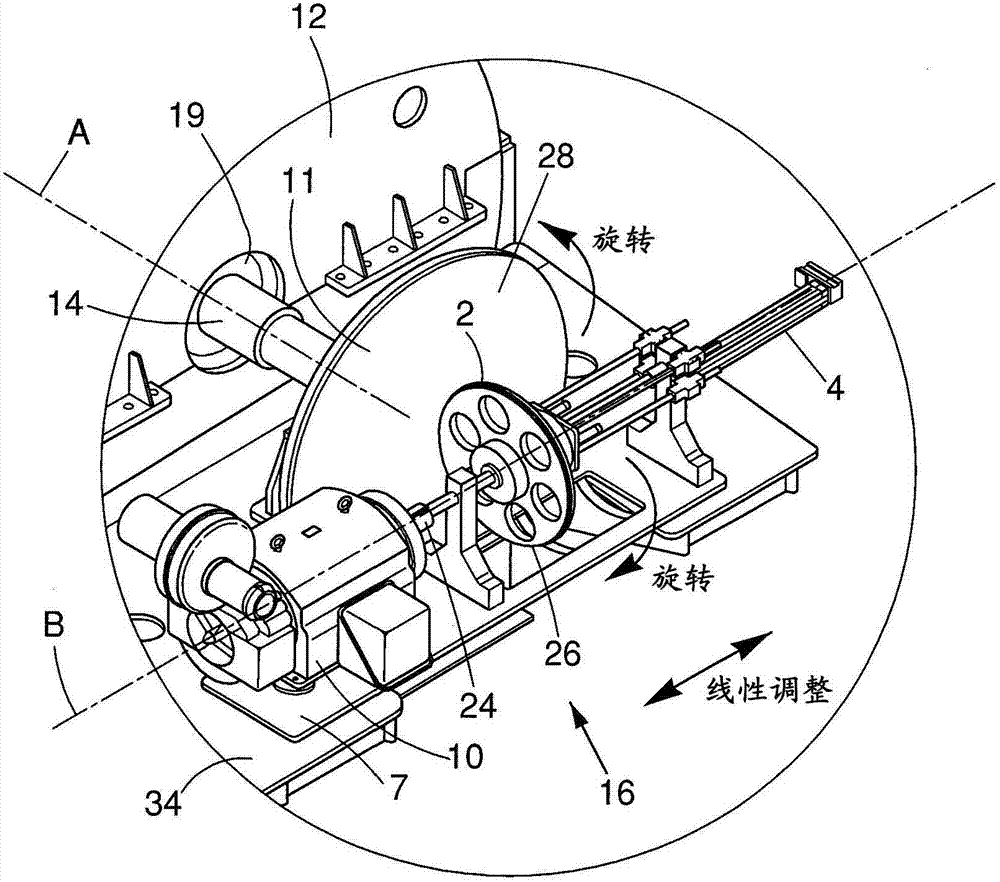

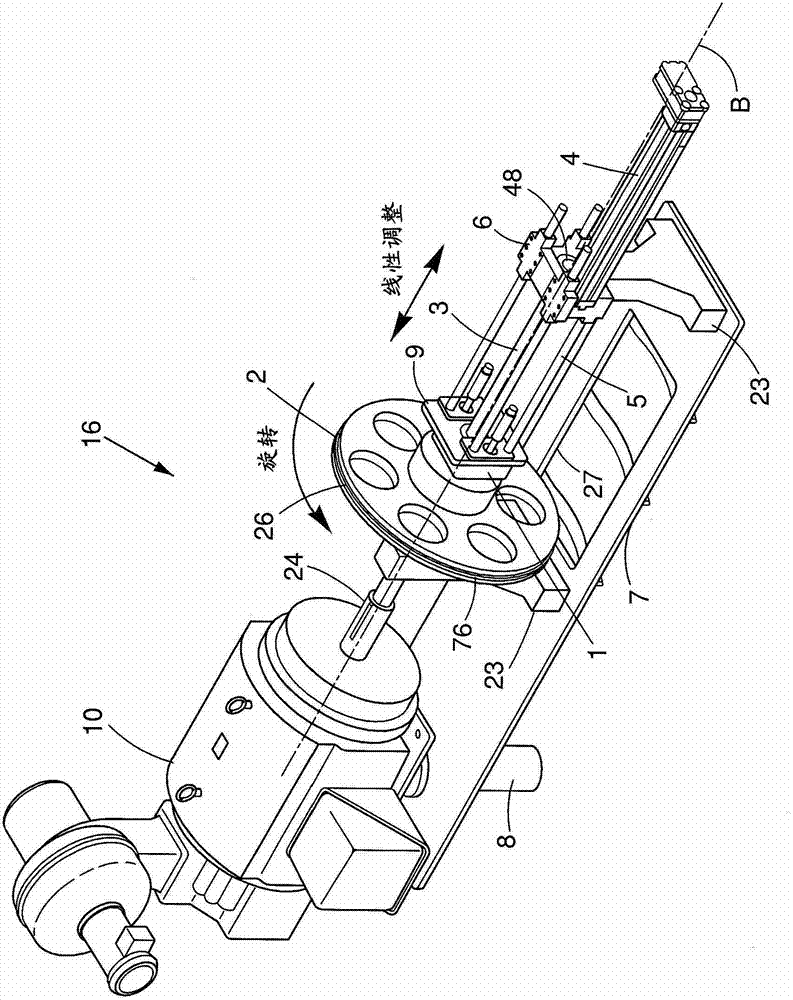

[0038] see Figures 1 to 6 , in one embodiment, the present invention may provide a flywheel system 25 having flywheel 12 rotatably coupled to motor drive assembly 16 (shown inside flywheel housing or housing 20 as seen through window 22 sections) and the generator drive assembly 18 on a support or mounting frame or bracket 34 . The environment inside the housing 20 may be in a vacuum state or have a low-density gas. The motor drive assembly 16 can bring the flywheel 12 to a desired rotational speed about the axis A, and can be adjusted to adjust the speed at which it drives the flywheel 12 . The generator drive assembly 18 can be adjusted to drive the generator 10a at a desired or constant speed, such as 1800 RPM, regardless of the speed at which the flywheel 12 is spinning. Flywheel 12 may be rotated by motor drive assembly 16 at a speed greater than 1000 RPM, for example, in some embodiments, in the range of 3000 RPM to 6000 RPM, and in some examples, up to about 10,000 R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com