Stereoscopic pocket and making method thereof

A production method and pocket technology, applied in clothing, clothing, application and other directions, can solve the problems of flat pockets, cannot hold heavy objects, easily hurt the body, etc., and achieve the effects of enhanced tensile strength, enhanced load-bearing capacity, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

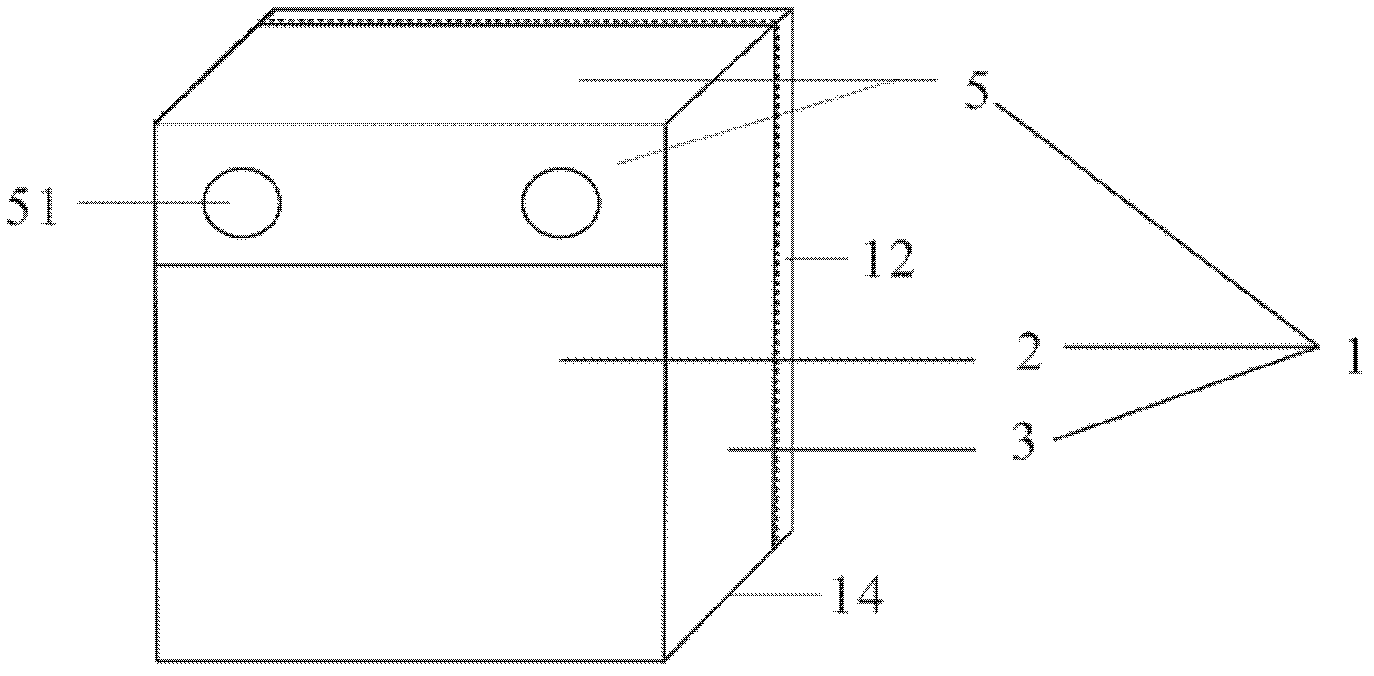

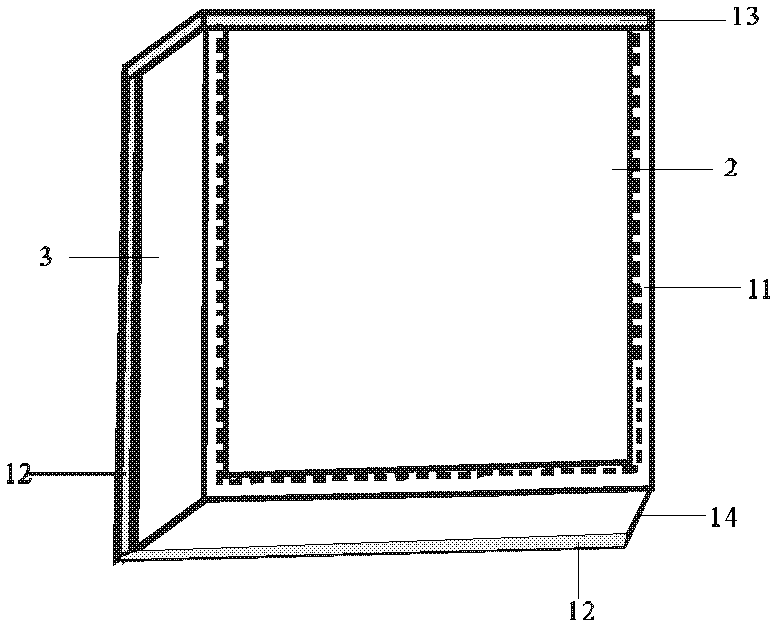

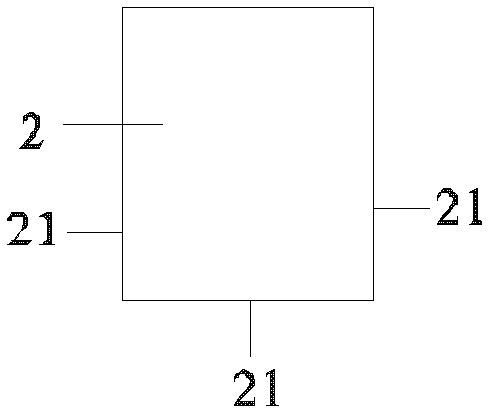

[0038] Example 1, such as figure 1 , 2 As shown in, 3, and 4, a stand-up pocket used to sew on a garment piece, comprising a main bag body 1, the main bag body 1 comprising a rectangular main panel 2 and a side panel 3, the side panel One side 31 of the panel 3 is sewn with the three sides of the main panel 2, and the other side 32 is sewn on the garment panel; the top of the unsewn main panel 2 and the two ends of the side panel 3 are formed Three-dimensional pocket opening. The seam of the main panel 2 and the side panel 3 is provided with a piping 11, and the other side 32 of the side panel 3 is respectively provided with a piping 12. The piping is mainly used to strengthen the edge connection and make the edge energy. Play a supporting role, but also prevent the edges of the pieces from being easily burred. Since one side 31 of the side panel 3 is stitched with the three sides 21 of the main panel 2, the side panel 3 is bent at the two bottom corners of the rectangular mai...

Example Embodiment

[0049] Example 2, such as Figure 5 As shown, in this embodiment, in addition to the main bag body 1 described in Embodiment 1, an auxiliary bag body 4 is also provided, that is, an auxiliary bag body 4 is provided outside the main panel 2. The auxiliary bag body 4 is sewn by a whole piece of inverted "convex"-shaped auxiliary cutting pieces, and two corners of the bottom are provided with seams 43 to support the bottom of the auxiliary bag body 4. The bottom and two side edges of the inverted "convex"-shaped auxiliary panel are turned upside down to form the bottom and sides of the auxiliary bag body 4, which are folded to form a folded edge 44 and a folded edge 42. The two lower ends of the auxiliary bag body 4 The corners are sewn together with back and forth seams 43, and the back and forth seams 43 play a role in supporting the auxiliary bag body 4.

[0050] When stitched on the garment part, the two side edges and bottom edge of the auxiliary bag body 4 are sandwiched betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com