Belt sander

An abrasive belt machine and abrasive belt technology, applied in the field of grinding devices and abrasive belt machines, can solve the problems of passing through large workpieces or special-shaped workpieces, difficult processing of large workpieces and special-shaped workpieces, etc., and achieve stable operation of the abrasive belt and convenient adjustment , The effect of fast replacement of the abrasive belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

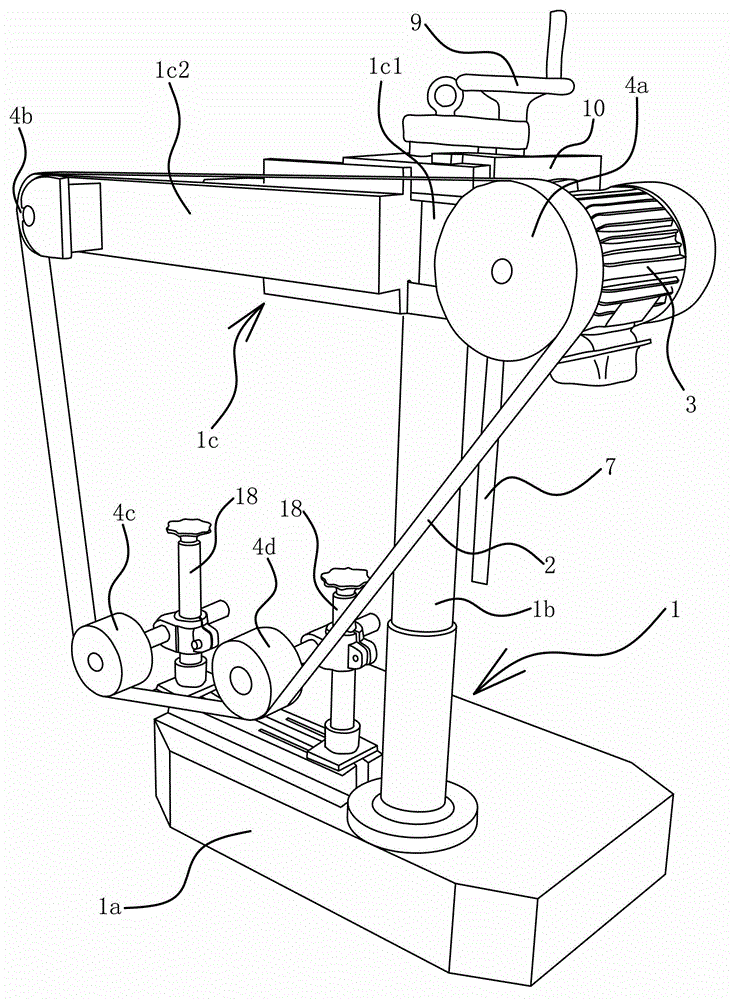

[0035] Such as figure 1 As shown, the abrasive belt machine includes a frame 1, an annular abrasive belt 2, a motor 3 and at least three pulleys 4. The pulleys 4 are all arranged inside the abrasive belt 2; the motor 3 is fixed on the frame 1; the rotating shaft of the motor 3 is connected with the pulley 4 therein. All the pulleys 4 are positioned on the frame 1 and can tension the abrasive belt 2, and the frame 1 has an escape space corresponding to the inner side of the abrasive belt 2.

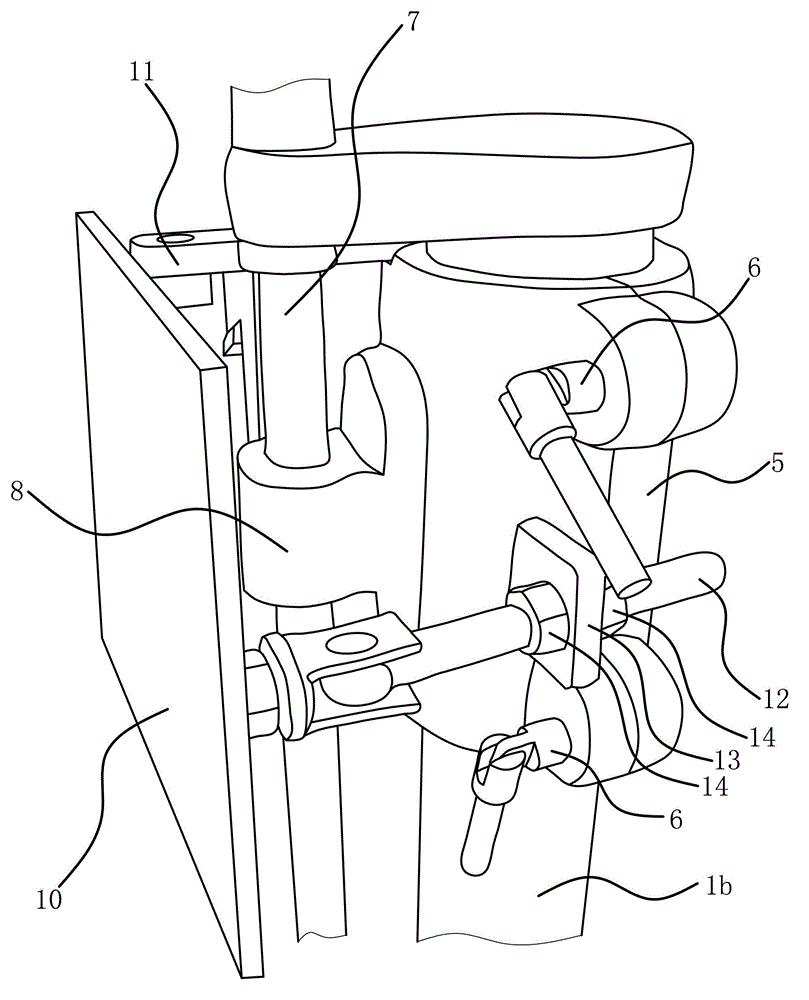

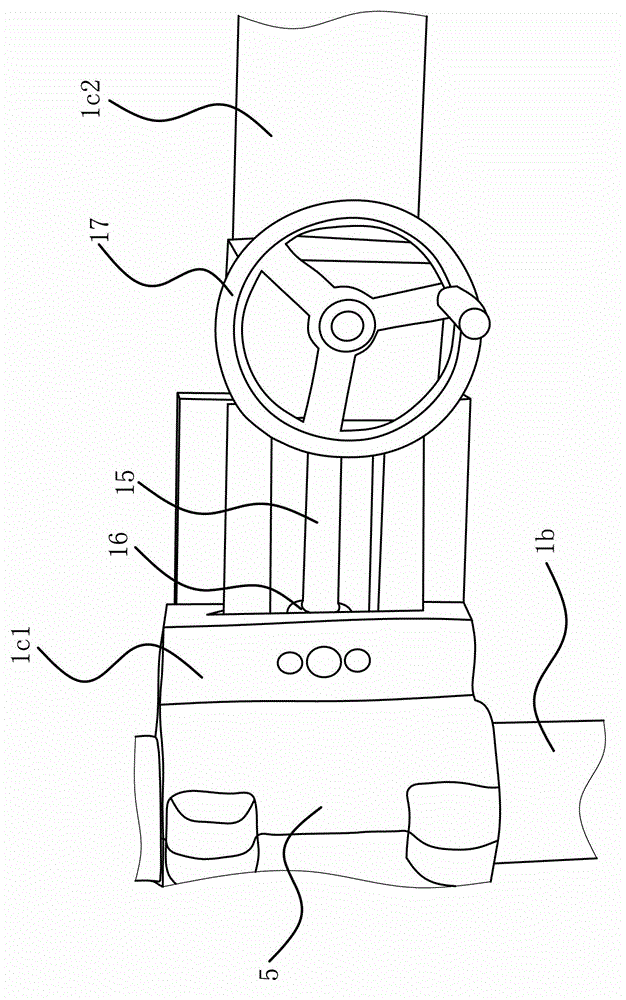

[0036] Specifically, the avoidance space is determined by the structure of rack 1; for example figure 1 As shown, the frame 1 includes a base 1a, a column 1b and a horizontal arm 1c. The lower end of the column 1b is fixedly connected to the base 1a by welding. One end of the horizontal arm 1c is fixedly connected to the upper end of the column 1b; figure 2 As shown, the column 1b is covered with a sliding sleeve 5, and the sliding sleeve 5 is provided with a locking member 6 that ena...

Embodiment 2

[0048] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the frame 1 includes a base 1a and two uprights 1b, and the lower end of the upright 1b is fixedly connected with the base 1a; the upper end of each upright 1b is positioned with A pulley 4, at least one pulley 4 is positioned on the base 1a. There is one pulley 4 positioned on the base 1a; the above pulley 4 is located in the middle of the two columns 1b. Or the number of pulleys 4 positioned on the base 1a is two; one above-mentioned pulley 4 is located directly below the pulley 4 positioned at the upper end of a column 1b; the other above-mentioned pulley 4 is located at the upper end of another column 1b Position the pulley 4 directly below.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap