Mold insert with Slanting alternating water channels and production method thereof

A waterway structure and alternating technology, which is applied in the field of mold inserts with inclined alternating waterway structure and its production, can solve the problems of poor product quality, poor cooling effect, transparency difference, etc., and achieve good product quality and good cooling effect , the effect of transparency balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

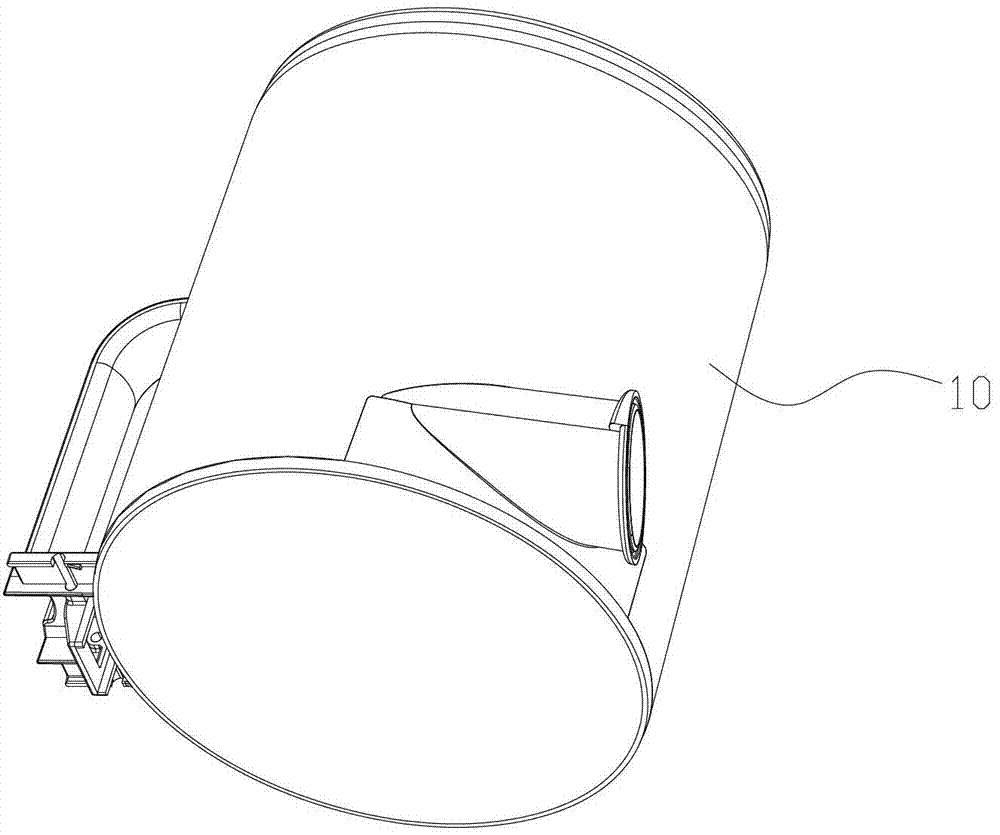

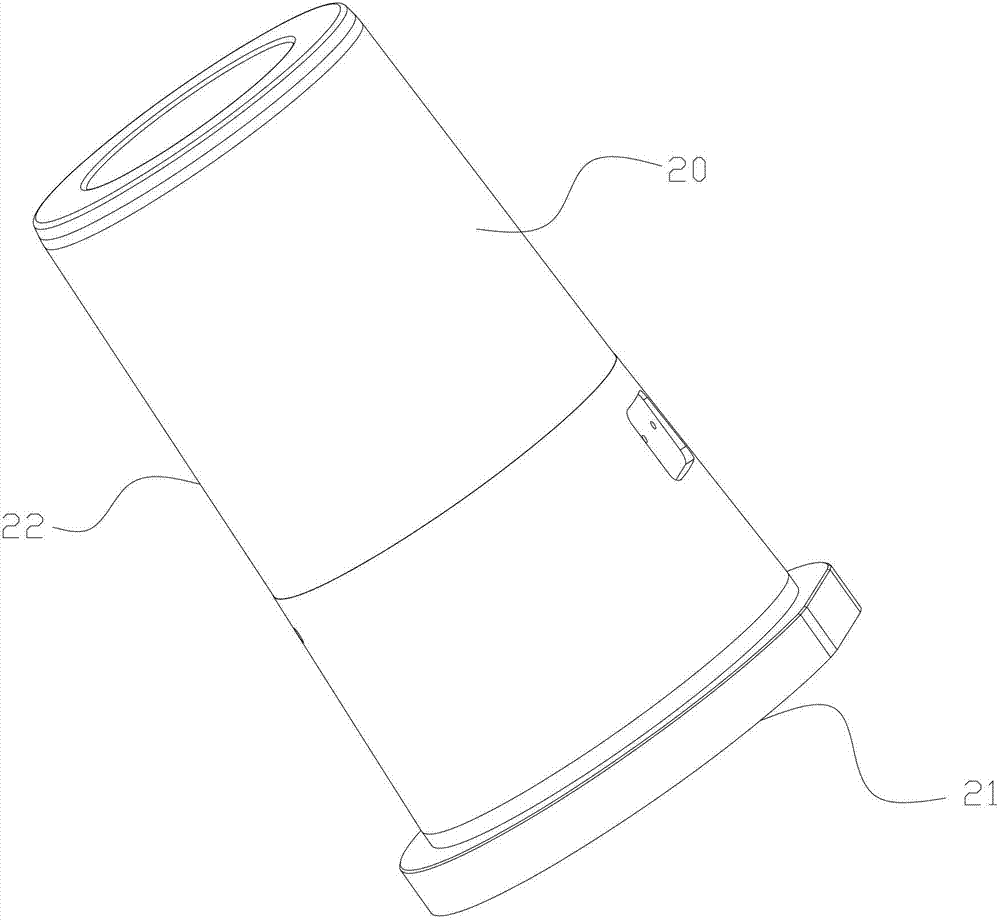

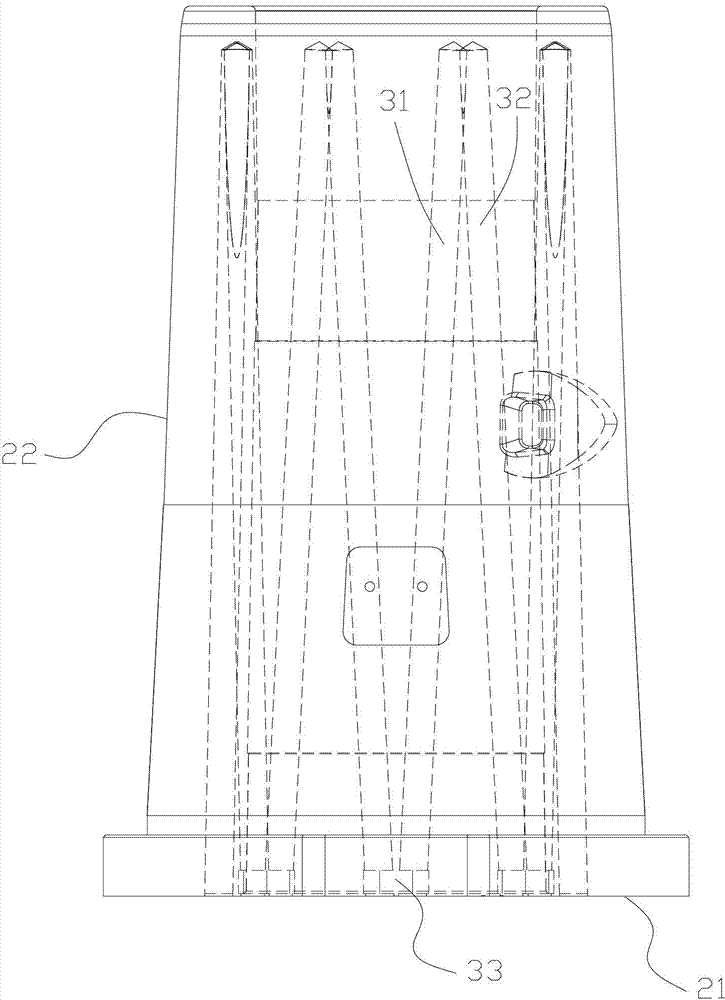

[0032] see Figure 3 to Figure 4 , the present invention provides a mold insert with an inclined alternating waterway structure for molding the inner surface of the plastic product 10 . The mold insert includes an insert body 20. The insert body 20 is a conical section with a circular bottom surface 21, and its outer wall is a conical surface 22. The insert body 20 is provided with 8 sets of inclined alternating waterway structure.

[0033] Each set of inclined alternating waterway structures includes a left inclined waterway 31 and a right inclined waterway 32, and the left inclined waterway 31 and the right inclined waterway 32 respectively penetrate from the circular bottom surface 21 of the insert body 20 and go upward. The straight line extends and intersects in the insert body 20, the angle between the axis of the left inclined waterw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com