Inversion-type glass curtain wall

A glass curtain wall and inverted technology, applied to walls, building components, buildings, etc., can solve problems such as increased cost, troublesome wire arrangement, and large size of stressed rods, so as to get rid of the dependence on scaffolding and reduce the pressure of funds , the effect of accurate positioning of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

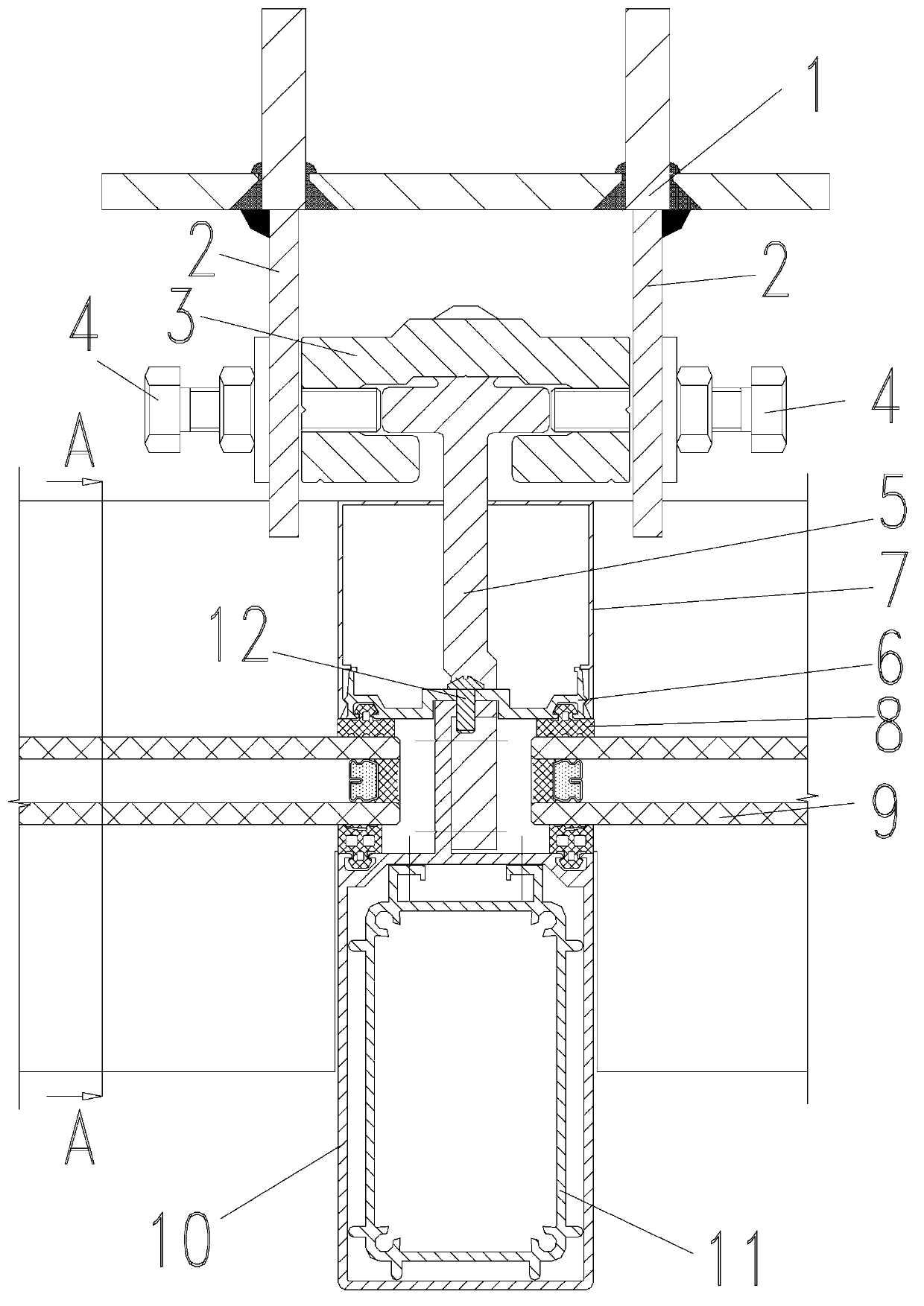

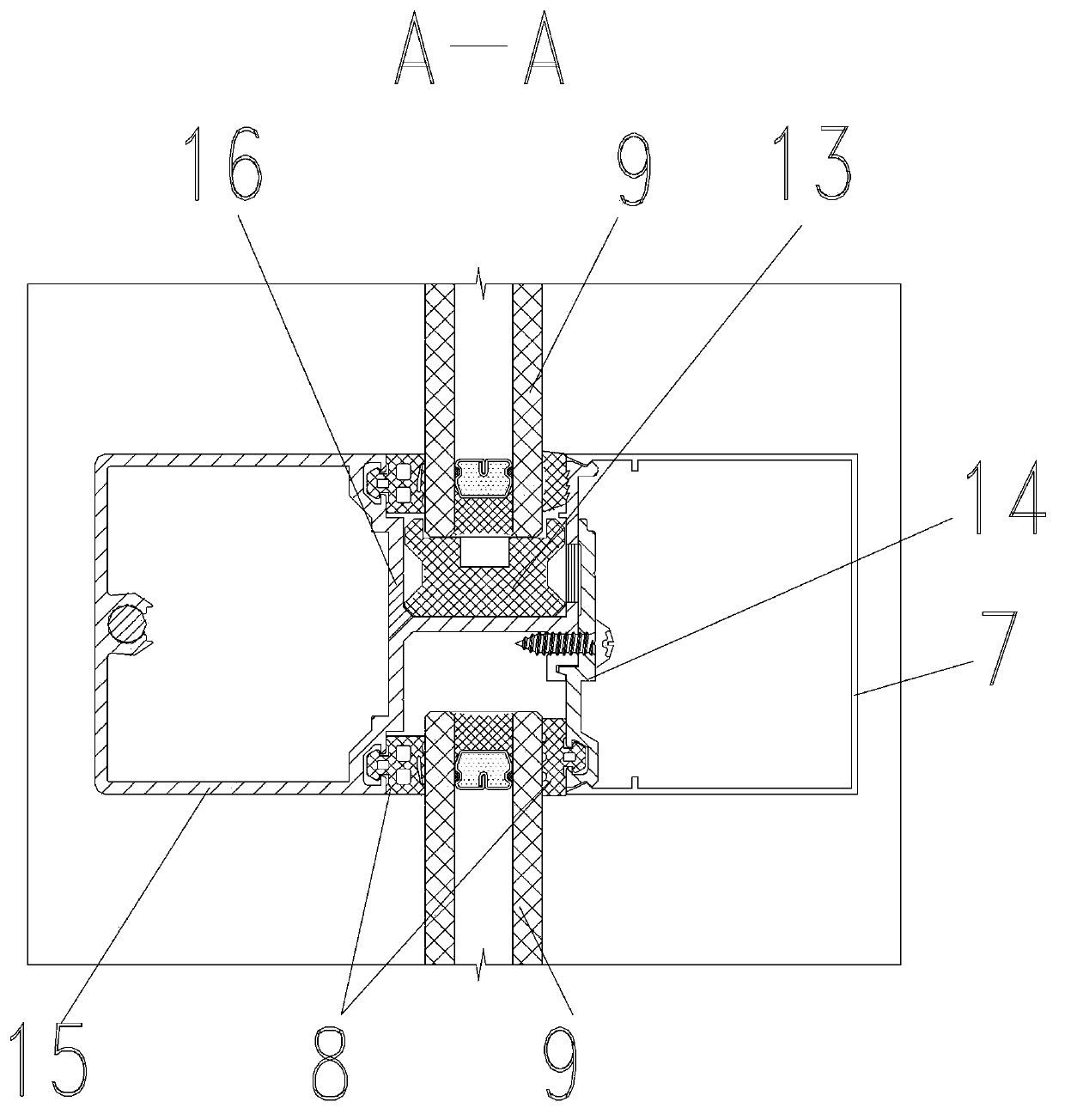

[0028] as attached figure 1 , 2 The shown inverted glass curtain wall of the present invention includes embedded parts 1, column hangers 3, column hangers 5, inner pressure plates 6, outer cover plates 7, glass 9, columns 10, and beams 15; The front end of the embedded part 1 is embedded in the wall (not shown); the rear end surface of the embedded part 1 is provided with a pair of side panels 2 arranged at intervals; the column hanging seat 3 is arranged between the side panels 2 In the gap; the upper end of the column hanger 5 is set on the column hanger 3, the lower end of the column hanger 5 is set on the column 10; the end of the glass 9 is set on the inside of the column 10, and the inner pressure plate 6 Press down; both sides of the column 10 are provided with glass 9; the inner pressure plate 6 collapses over the column 10, and is fixed on the column 10 with screws 12; the crossbeam 15 is connected with the column 10; the end of the glass 9 A sink plug 13 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com