Pipe fitting connector

A technology of connecting parts and pipe fittings, which is applied in the direction of connecting components, rods, mechanical equipment, etc., can solve the problems of affecting pipe fittings and improving strength, and achieve the effects of convenient installation/disassembly, beautiful appearance and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

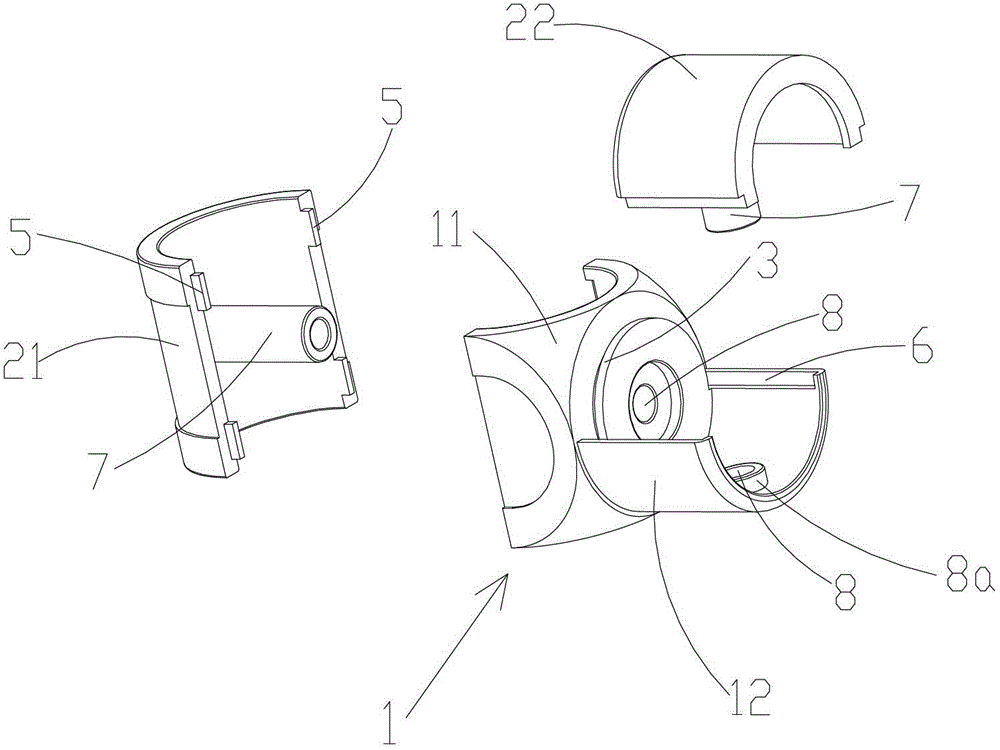

[0021] Such as Figure 1-3 As shown, the pipe connector of this embodiment includes a base 1 with two connecting parts and two housings, namely the first housing 21 and the first connecting part 11, the second housing 22 and the second connecting part 12. The second connecting part 12 is arranged on the outer surface of the first connecting part 11 and its axial direction is perpendicular to the axial direction of the first connecting part. An outwardly protruding, stepped first flange 3 is formed, and a corresponding second flange 4 is formed at the bottom of the second housing 22, and the second flange 4 can extend into the connection formed under the first flange 3 In slot 31.

[0022] The shape of the inner surface of the housing and the connecting part corresponds to the shape of the outer surface of the connected pipe fitting and can be covered on the pipe fitting. Here it is a circular arc surface, which is suitable for connecting circular pipe fittings. The connecting...

Embodiment 2

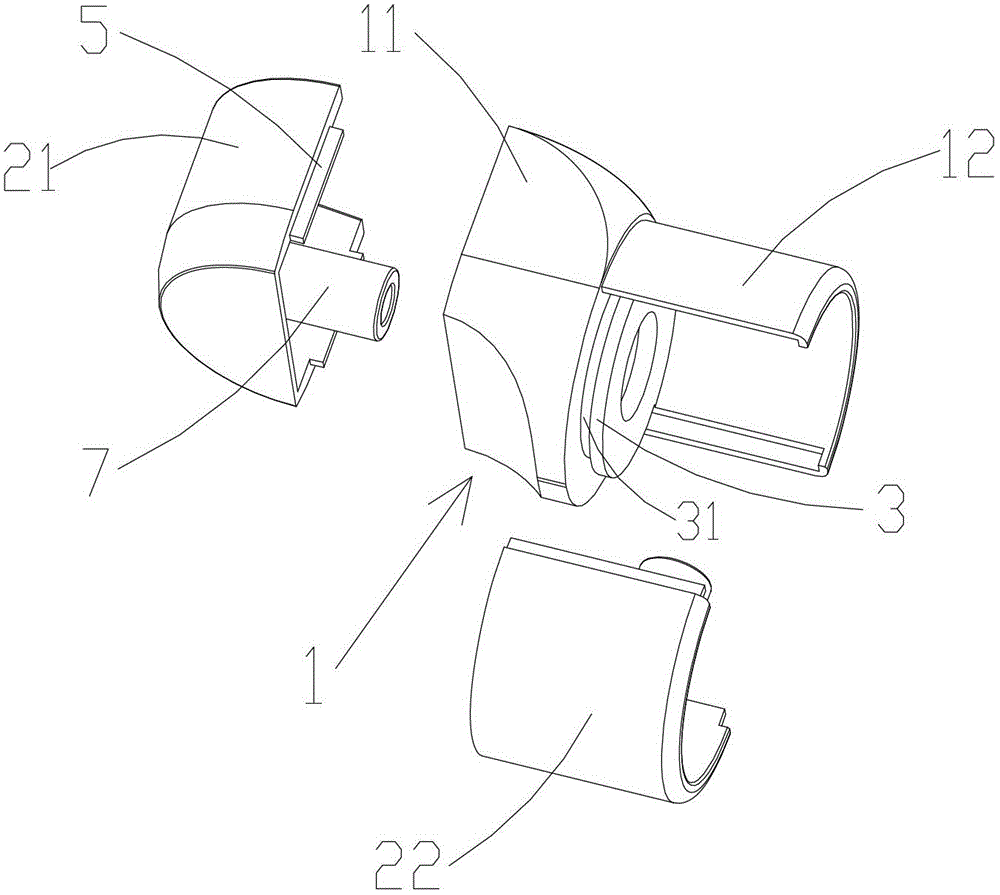

[0025] Such as Figure 4-5 As shown, the difference between this embodiment and Embodiment 1 is that the number of the housings and the connecting parts is three, namely the first housing 21 and the first connecting part 11, the second housing 22 and the connecting part 11 respectively. The second connection part 12, the third housing 23 and the third connection part 13, the second and third connection parts 12, 13 are arranged on the outer surface of the first connection part 11 and the second and third connection parts 12, 13 The axial directions are respectively perpendicular to the axial direction of the first connecting portion 11. On the outer surface of the first connecting portion 11, the joints of the second and third connecting portions are respectively formed with protruding, stepped first The protruding edge 3 forms a corresponding second protruding edge 4 at the bottom of the second and third shells 22 , 23 , and the second protruding edge 4 can extend into the co...

Embodiment 3

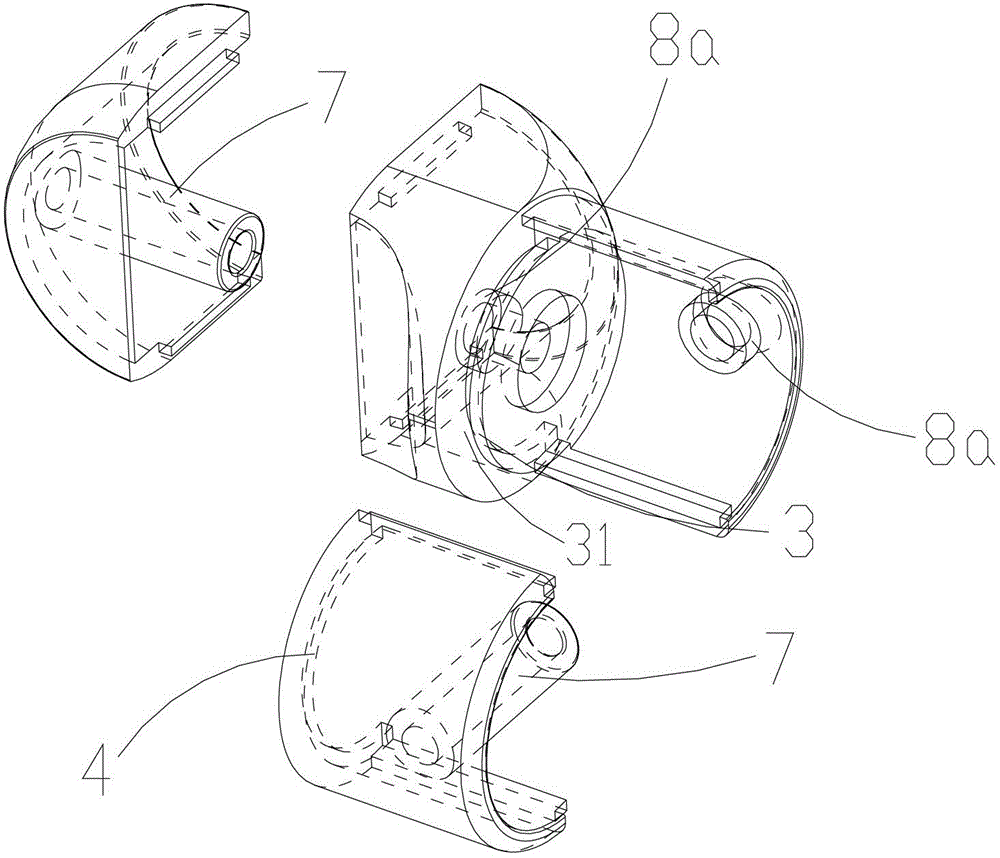

[0028] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the number of the housings and the connecting parts is four, respectively the first housing 21 and the first connecting part 11, the second housing 22 and the The second connection part 12, the third housing 23 and the third connection part 13, the fourth housing 24 and the fourth connection part 14, the second, third and fourth connection parts 12, 13, 14 are arranged on the first connection The outer surface of the first connecting part 11 and the axial directions of the second, third and fourth connecting parts 12, 13, 14 are respectively perpendicular to the axial direction of the first connecting part 11. On the outer surface of the first connecting part 11, the second 2. The joints of the third and fourth connecting parts form outwardly protruding, stepped first protruding edges 3 respectively, and corresponding second protruding edges 4 are formed at the bottom of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com