Plumb line horizontal displacement monitoring method and system

A monitoring system and plumb line technology, applied in plumb lines, measuring devices, measuring instruments, etc., can solve the problem of high monitoring costs, and achieve the effect of reducing monitoring costs, reducing the workload of system installation, and reducing the amount of settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

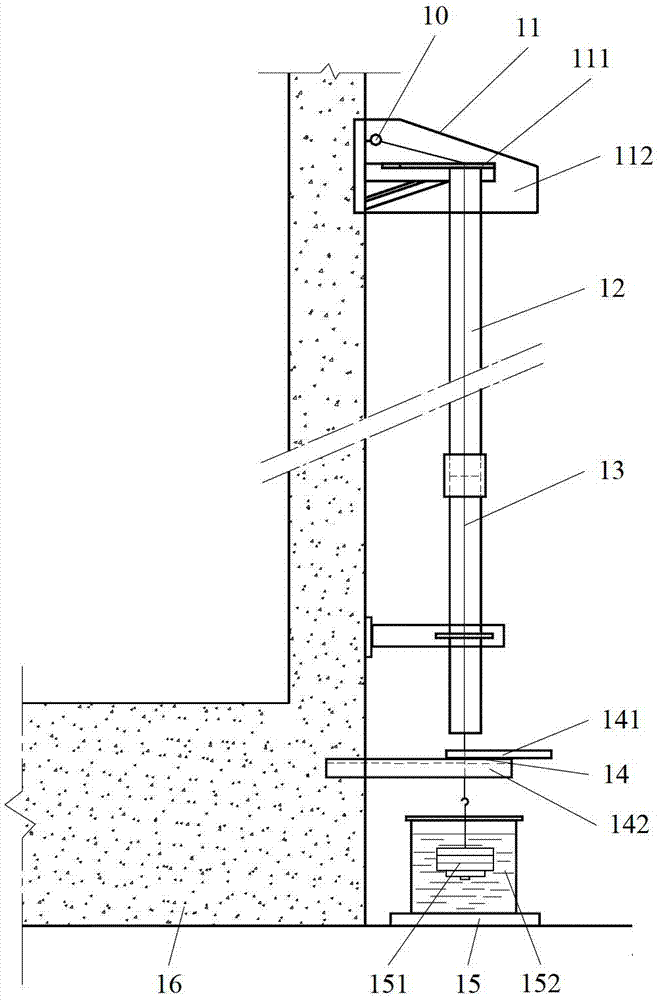

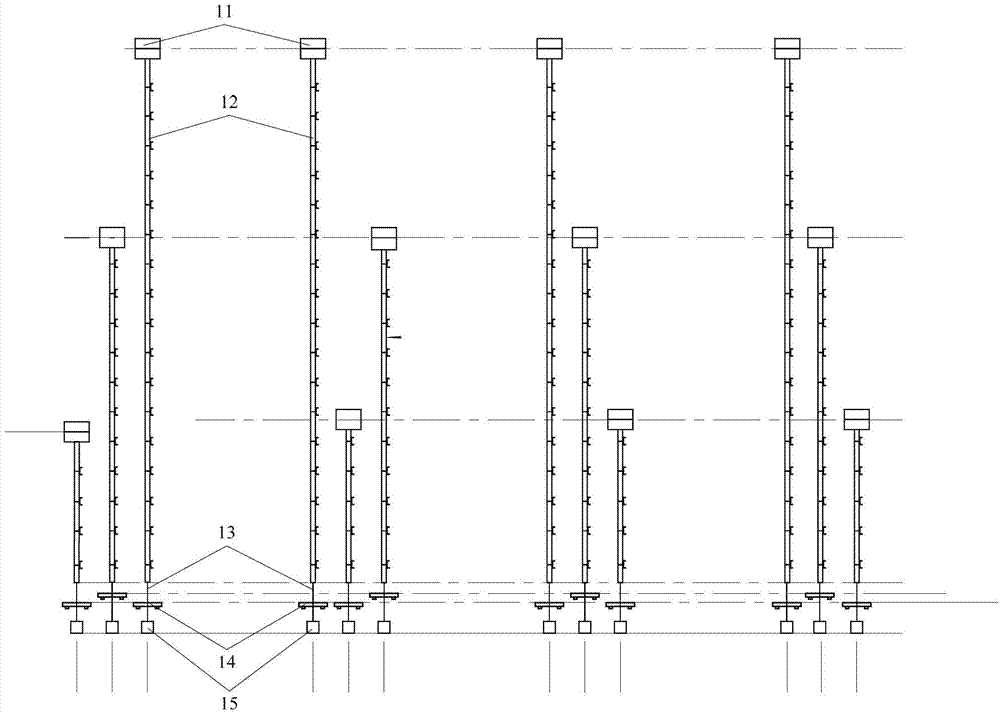

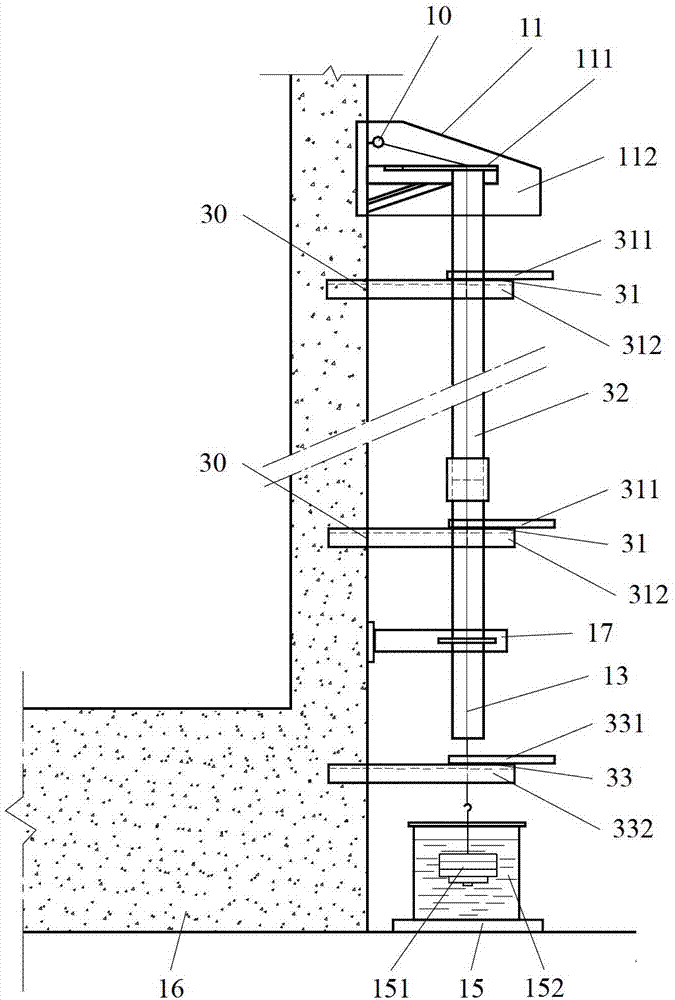

[0050] image 3 It is a structural schematic diagram of the plumb line horizontal displacement monitoring system in the embodiment of the present invention. Such as image 3 As shown, the plumb line horizontal displacement monitoring system in the embodiment of the present invention includes: measuring point device 11, plumb line 13, reading device 33, weight damping device 15, plumb line protection tube composed of multiple sections of protection tube 32 and at least one newly added reading device 31.

[0051] Wherein, the measuring point device 11 is arranged on the measuring point 10 of the structure to be monitored, and the measuring point device 11 includes an upper end support 111 arranged below the measuring point 10 and surrounding the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com