Stacker, automated three-dimensional warehouse and method of entering and leaving the automated three-dimensional warehouse

A technology of three-dimensional warehouse and stacker, applied in the field of three-dimensional warehouse, can solve the problems of high construction cost of a single stacker, increased cost of three-dimensional warehouse, high cost of construction of three-dimensional warehouse, etc. The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

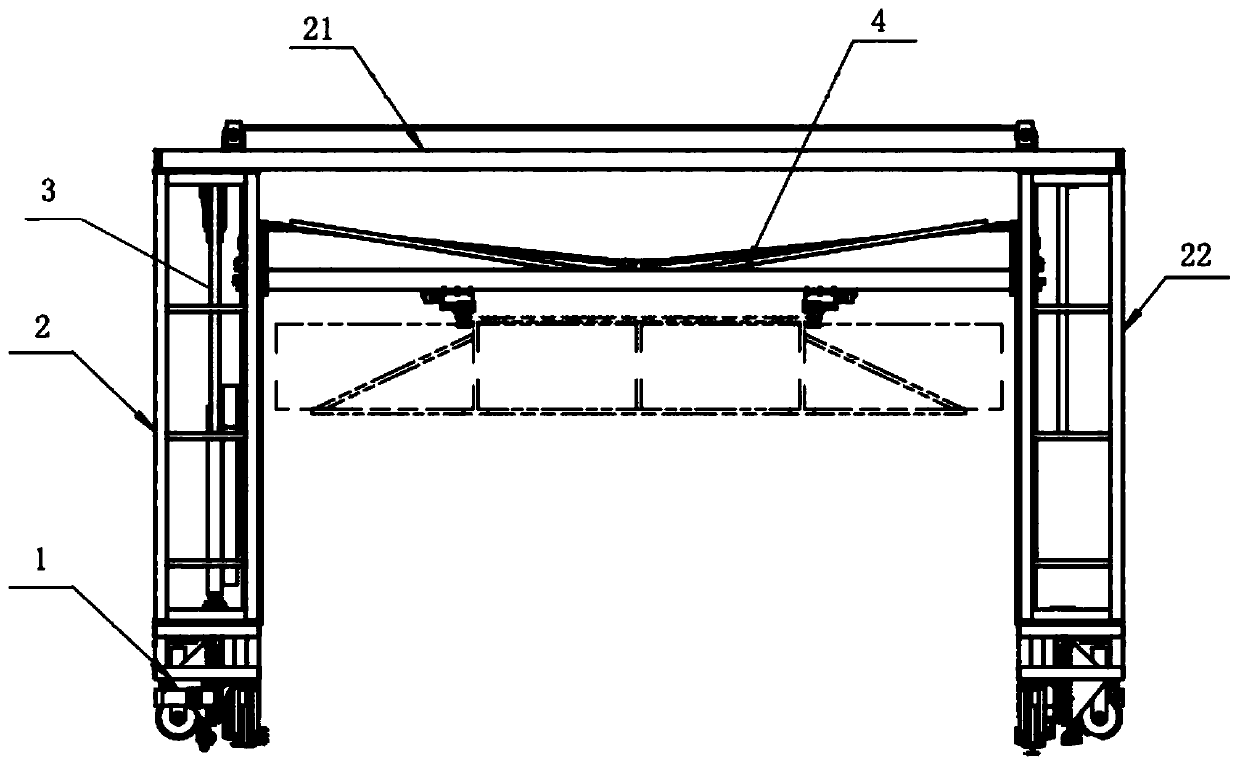

[0033] Such as figure 1 As shown, the present embodiment provides a stacker, including a gantry 2 , a lifting mechanism 3 , a grabbing mechanism 4 and a traveling mechanism 1 .

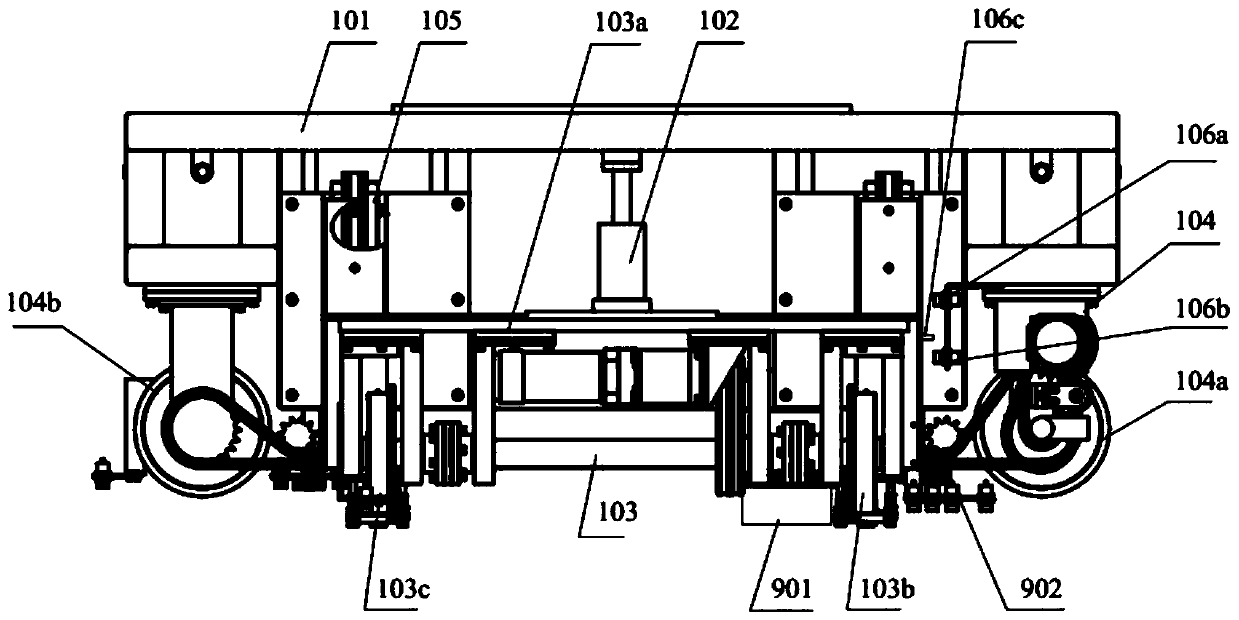

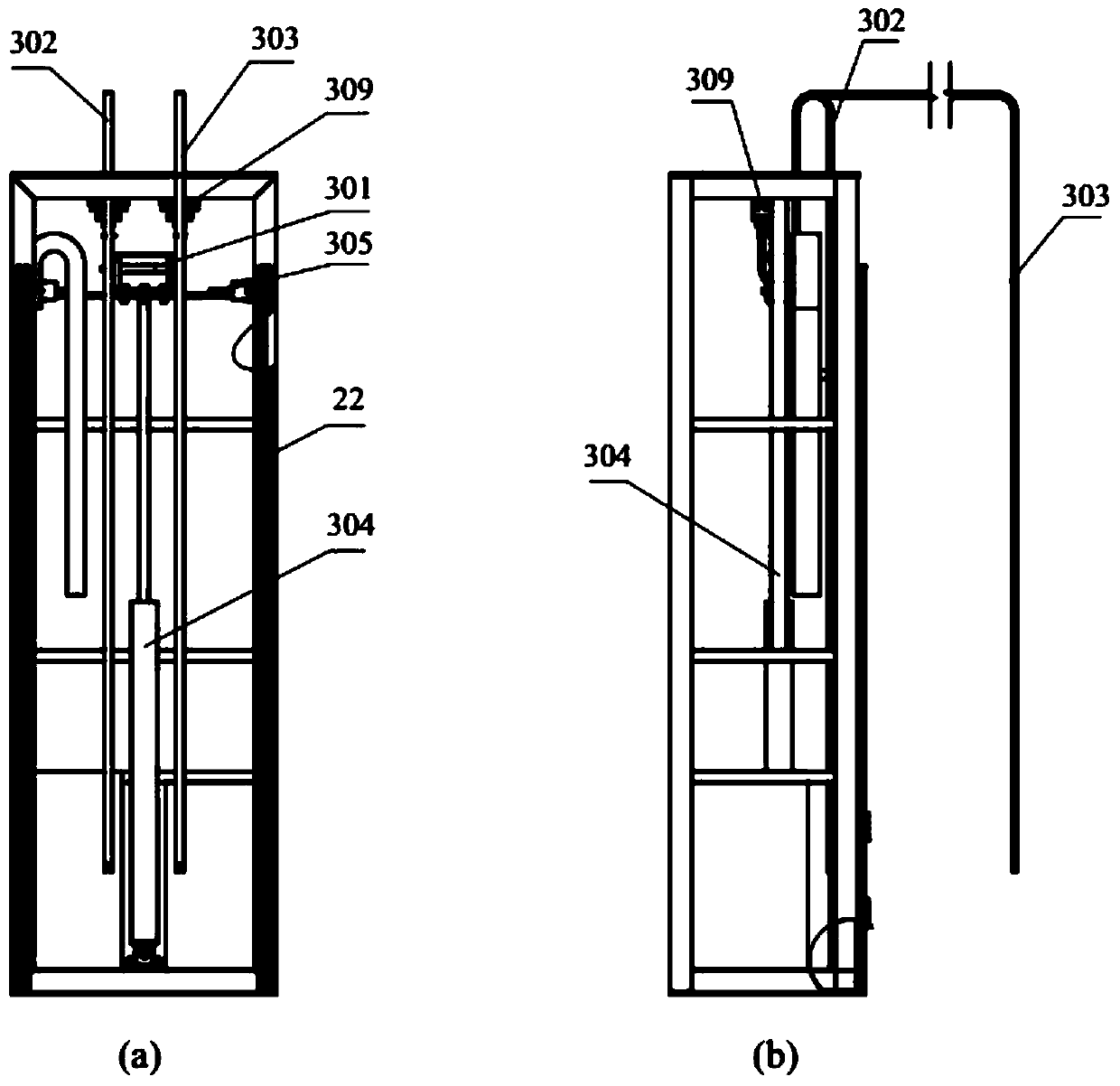

[0034] The gantry frame 2 includes two vertical frames 22 and cross beams 21 arranged on the tops of the two vertical frames 22 , and the bottoms of the two vertical frames 22 are provided with running gears 1 with the same structure. When setting, the gantry 2 is straddled above the shelf, that is, one stand 22 is located on one side of the shelf, the other stand 22 is located on the other side of the shelf, one walking mechanism 1 walks on the track on one side of the shelf, and the other walks Mechanism 1 walks on the track on the other side of the shelf, so that when the goods are accessed, only the lifting mechanism 3 is needed to move up and down, and there is no need for the lifting mechanism 3 to move left and right, so as to avoid the problem of eccentricity. Such as figure 2 As shown, the...

Embodiment 2

[0041] Such as Figure 6 As shown, this embodiment provides an automated three-dimensional warehouse, including a warehouse management system, a stacker control system communicatively connected with the warehouse management system, four horizontally arranged row track groups 801, and three vertically arranged column track groups 802 and the stacker in Embodiment 1, each row track group 801 intersects with each column track group 802; the row track group 801 and the row track group 802 are composed of two mutually parallel tracks, and each row track group Between the two tracks of 801 there are 84 cargo spaces 803 evenly arranged, and the number of layers of cargo frames placed on each cargo space 803 can be set as required. One X of the stacker is walking on a track of the row track group 801 to the walking wheel assembly 104, and another X is walking on another track of the row track group 801 to the walking wheel assembly 104, that is, the two tracks of the stacker A vertic...

Embodiment 3

[0050] The warehouse management system integrates the functions of batch management, material correspondence, inventory inventory, quality inspection management, virtual warehouse management and real-time inventory management through the functions of inbound business, outbound business, warehouse transfer, inventory transfer and virtual warehouse management. The advanced management system is used to effectively control and track the whole process of logistics and cost management of warehouse business, and realize perfect enterprise warehouse information management. The system can perform inventory operations independently, and can be used in combination with documents and vouchers from other systems to provide more complete and comprehensive business process and financial management information.

[0051]This embodiment provides a method for entering and exiting the automated three-dimensional warehouse in Embodiment 2, including the steps of entering and exiting the warehouse: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com