Motor rotor structure, permanent-magnet synchronous motor and variable-frequency compressor

A permanent magnet synchronous motor and motor rotor technology, which is applied in the field of variable frequency compressors, can solve the problems of insufficient back-EMF waveform sine, affecting the performance of permanent magnet synchronous motors, and low efficiency of permanent magnet synchronous motors, so as to improve product competitiveness, The effect of optimizing the magnetic circuit and improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

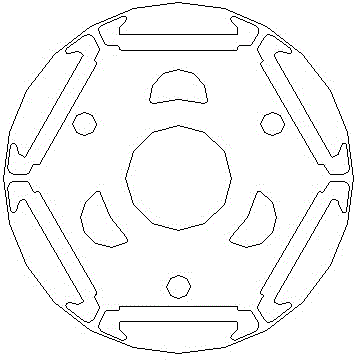

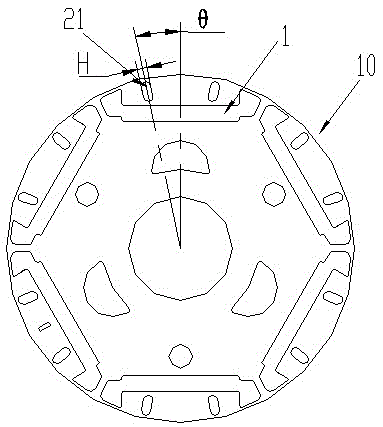

[0023] see image 3 The motor rotor structure of the present invention is a built-in permanent magnet structure, and a magnetic isolation hole 21 is provided on the outer side of the magnetic steel slot hole 1 of the rotor 10 .

[0024] The angle θ between the geometric centerline of the magnetic isolation hole and the magnetic pole centerline satisfies the relationship:

[0025] 180° / (np)-2°≤θ≤180° / (np)+2°, where n is the nth harmonic, and p is the pole logarithm.

[0026] In this embodiment, the angle θ between the geometric centerline of the magnetic isolation hole and the magnetic pole centerline is θ=180° / (np)=180° / (5*3)=12°.

[0027] The magnetic isolation holes are arranged symmetrically along the centerline of the magnetic poles. In this embodiment, there are altogether 12 magnetic isolation holes.

[0028] exist image 3 In the first embodiment shown, the magnetic isolation hole 2 is oblong, and the magnetic isolation hole has a certain width H, and the width H of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com