Central supporting bearing of external boring machine

A center support and bearing technology, applied in the direction of boring/drilling, parts of boring machine/drilling machine, drilling/drilling equipment, etc. The effect of shape and position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

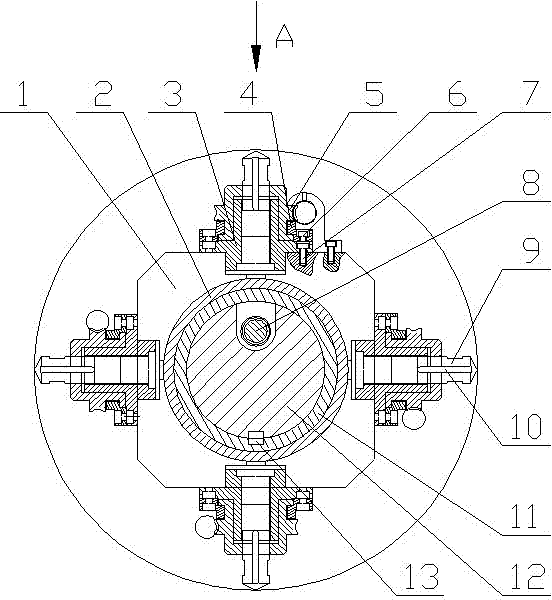

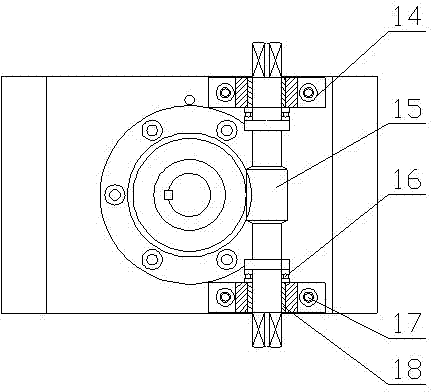

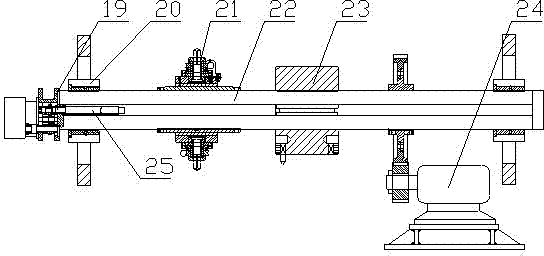

[0037] see Figure 1~Figure 3 , the present invention is a center support bearing for external boring and boring, which includes a bearing housing 1, a copper bearing 2 is arranged in the bearing housing 1, an iron bushing 11 is arranged in the copper bearing 2, and the iron bushing The sleeve 11 is set on the outer boring bar 12, the iron bushing 11 and the outer boring bar 12 are connected by positioning keys 13, and the bearing housing 1 is evenly arranged with four sets of worm gear mechanisms in the circumferential direction. The worm gear mechanism includes a flange 3 and a half flange 4, the flange 3 is fixedly connected to the bearing housing 1 through the first bolt 6, and the half flange 4 is connected to the half flange through the second bolt 7. The blue plate 3 is fixedly connected, and a center frame worm gear 5 is arranged between the flange plate 3 and the half flange 4, and the center frame worm gear 5 is set on the flange plate 3, and one side of the flange p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com