Capacity-adjustable liquid filling mechanism

An adjustable and liquid technology, which is applied in the direction of liquid materials, packaging, transportation and packaging, etc., can solve the problems affecting the running speed and packaging quality of packaging machines, reducing packaging accuracy and yield, and unstable air pressure, so as to improve packaging accuracy and packaging yield, guaranteed running speed and packaging quality, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

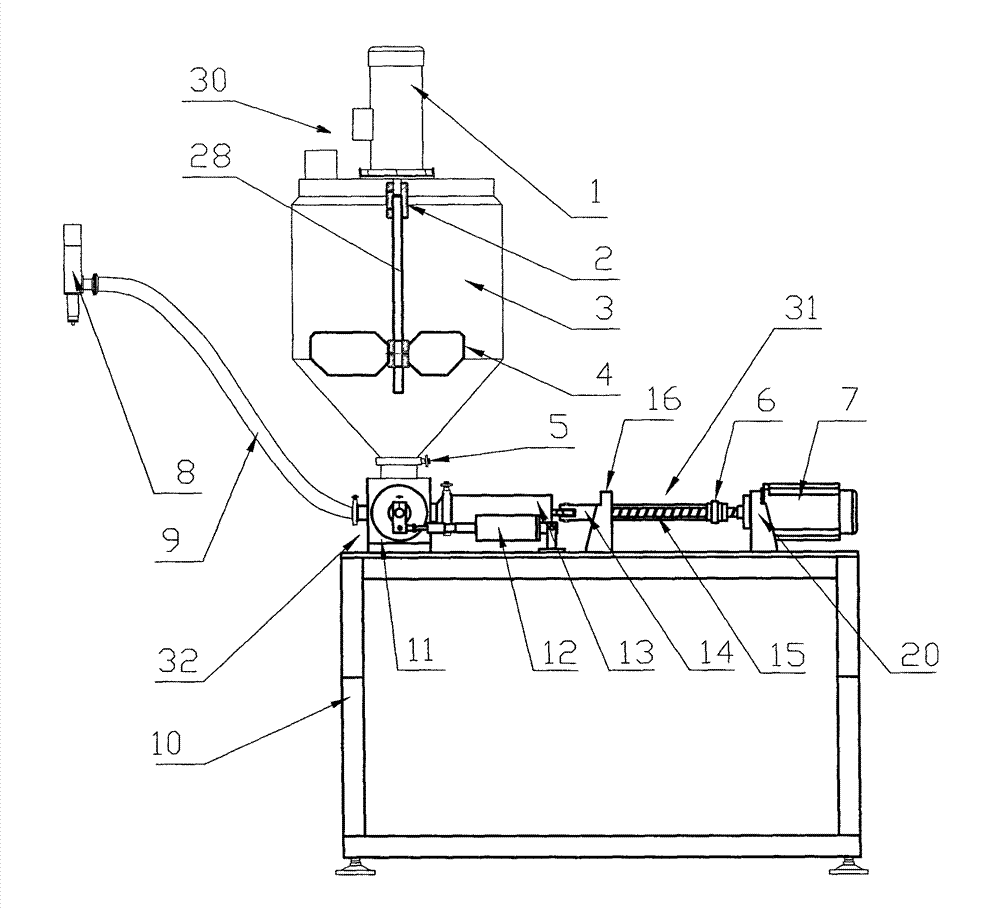

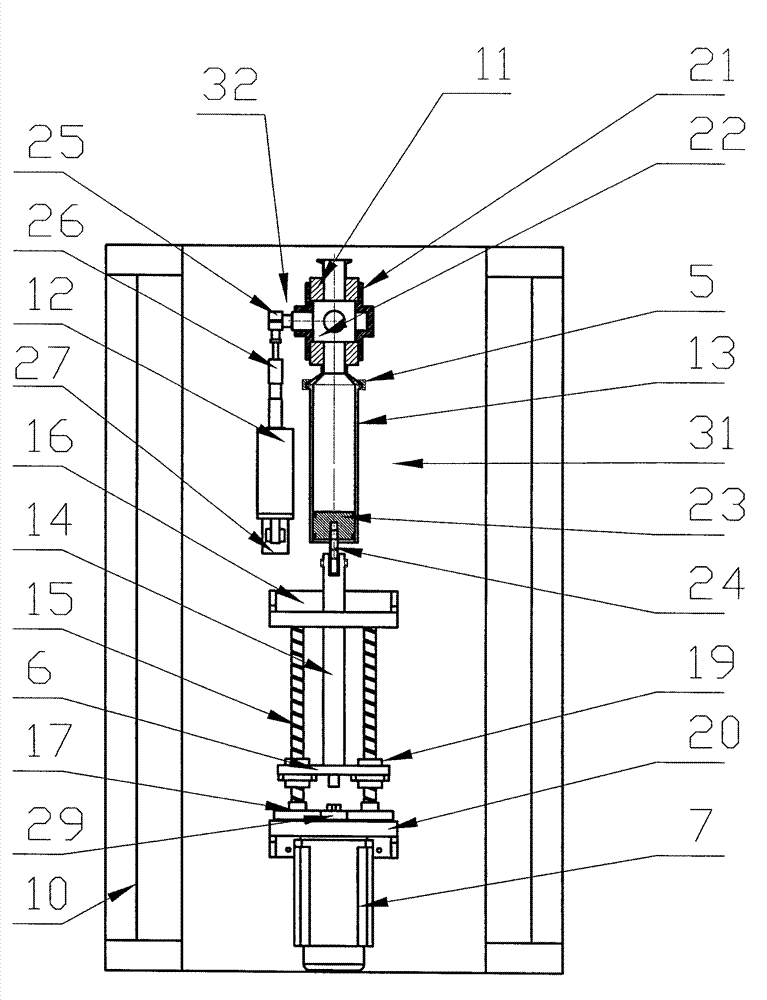

[0008] refer to figure 1 , figure 2 , the present invention is applied to a capacity-adjustable liquid filling mechanism for a bag-type packaging machine, including a frame 10, a liquid input device 30, a liquid pushing device 31, and a valve adapter device 32. The liquid pushing device 31 includes a cylinder 13, The piston 23, the outer end of the piston 23 of the liquid pushing device 31 (through the joint bearing 24) is connected with the connecting rod 14, and the connecting rod 14 is connected with the feed screw 15 through the guide block 6 with the nut 19, and the feed wire The rod 15 is connected to the push motor 7 through an intermediate conveying assembly (comprising a screw gear 17 mounted on the feed screw rod and a motor gear 29 mounted on the push motor shaft) that mesh with each other.

[0009] Wherein, the push motor 7 is mounted on the frame 10 through the rear support 20 , and the feeding screw 15 is mounted on the frame 10 through the front support 16 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com