Packing capacity automatic adjusting mechanism

A technology of automatic adjustment and packaging volume, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items. It can solve the problems of low work efficiency, affecting the running speed of the packaging machine, time-consuming and laborious, etc., to achieve high work efficiency and ensure running speed. , The effect of high adjustment precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

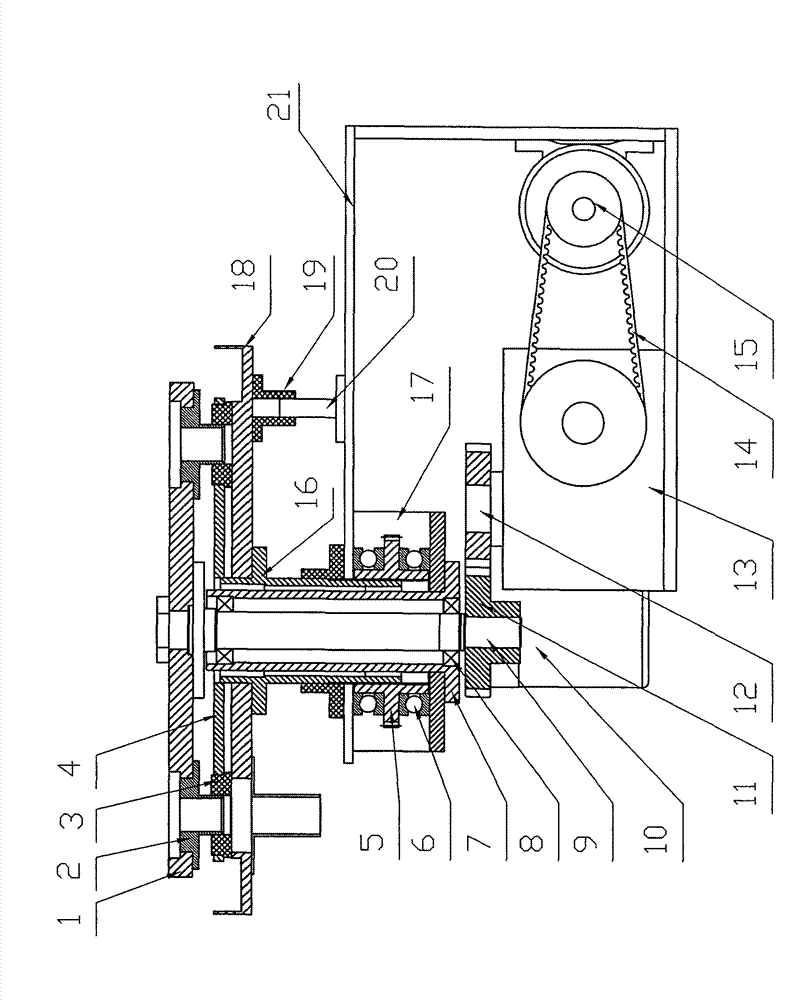

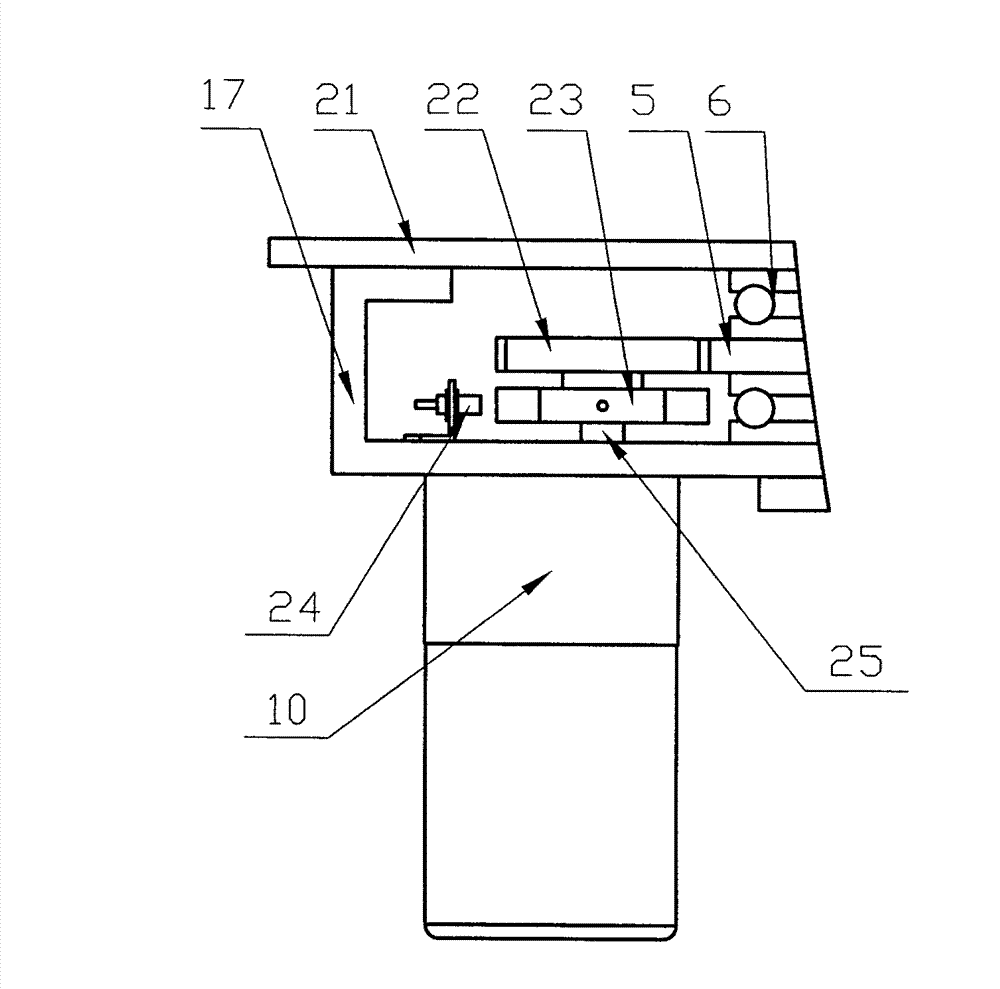

[0010] refer to Figure 1 to Figure 3 As shown, the present invention is applied to the packaging volume automatic adjustment mechanism of the bag-feeding packaging machine, including an upper turntable 1, a measuring cup 2, a middle turntable 4, and a lower turntable 18. Connect, on the periphery of the rotating shaft 9, and at the lower turntable place, the auxiliary gear 5 is equipped with the guide sleeve 16, and the auxiliary gear 5 is connected with the lifting motor 10 through the motor gear 22.

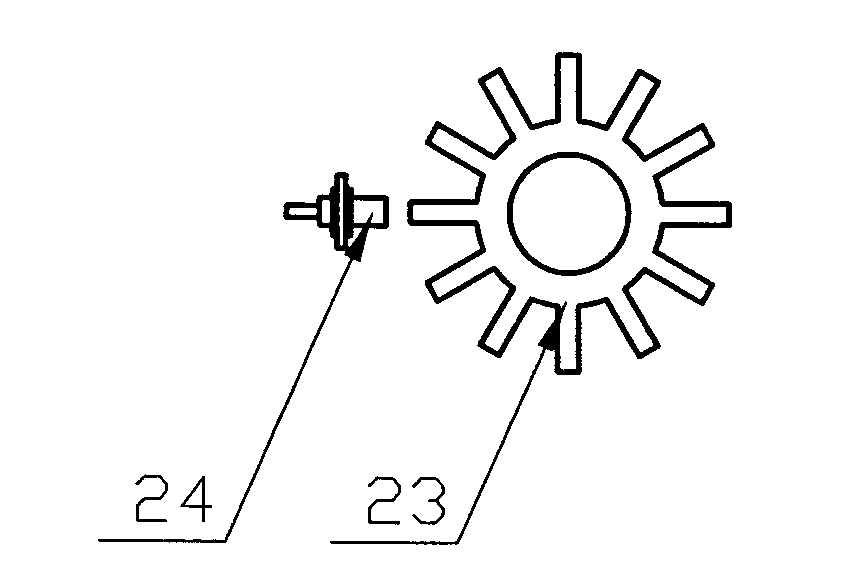

[0011] On the motor shaft 25 of the lifting motor 10, a counting sheave 23 is also installed, and on the mount 17 of the lifting motor 10, a proximity switch 24 corresponding to the position of the counting sheave is installed. The motor shaft is driven by the lifting motor to rotate the counting sheave, and the teeth of the counting sheave are induced by the proximity switch. The number of the teeth is consistent with the number of inductions, so that the counting sheave and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com