Device and method for detecting broken strands of hoisting steel wire rope

A detection device and detection method technology, applied in the elevator field, can solve the problems of shortening the service life of the sheave, slipping, trapping people, etc., and achieve the effects of accurate fault judgment, passenger safety protection, and mature production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

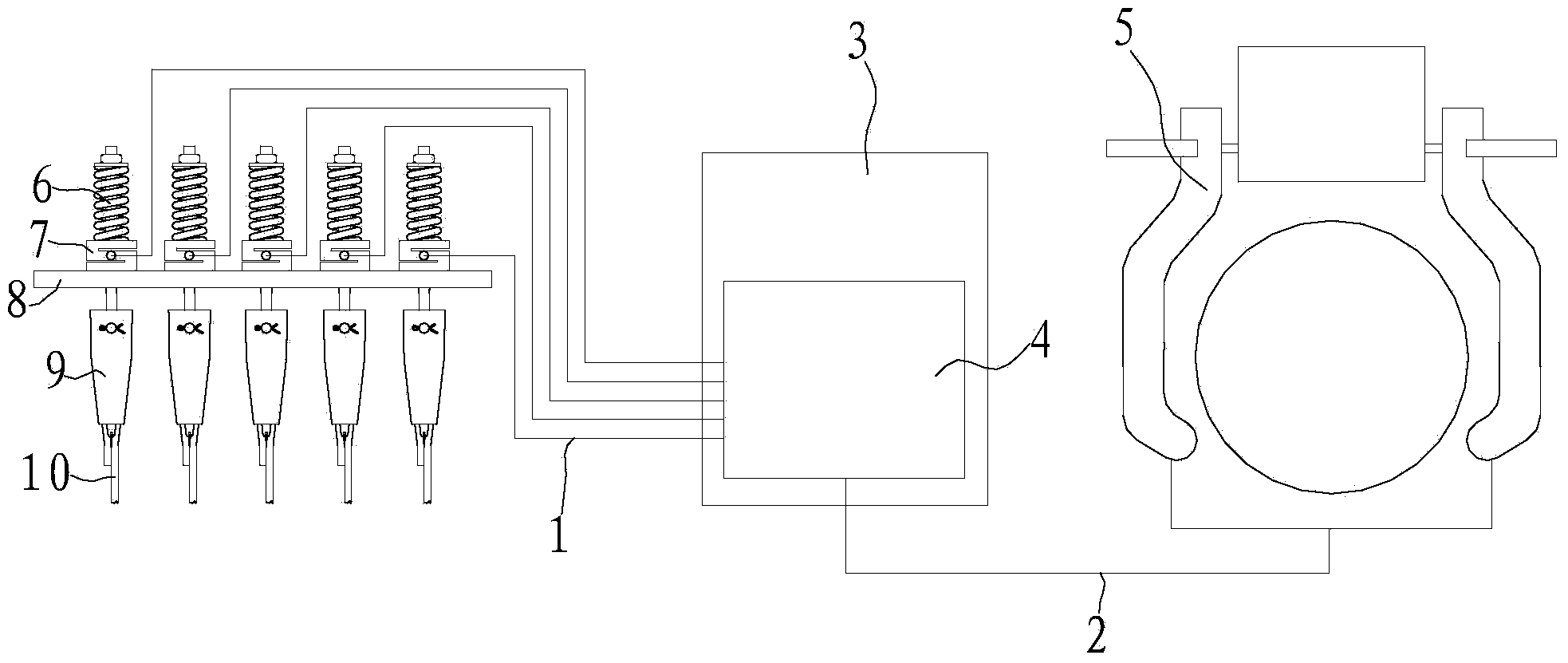

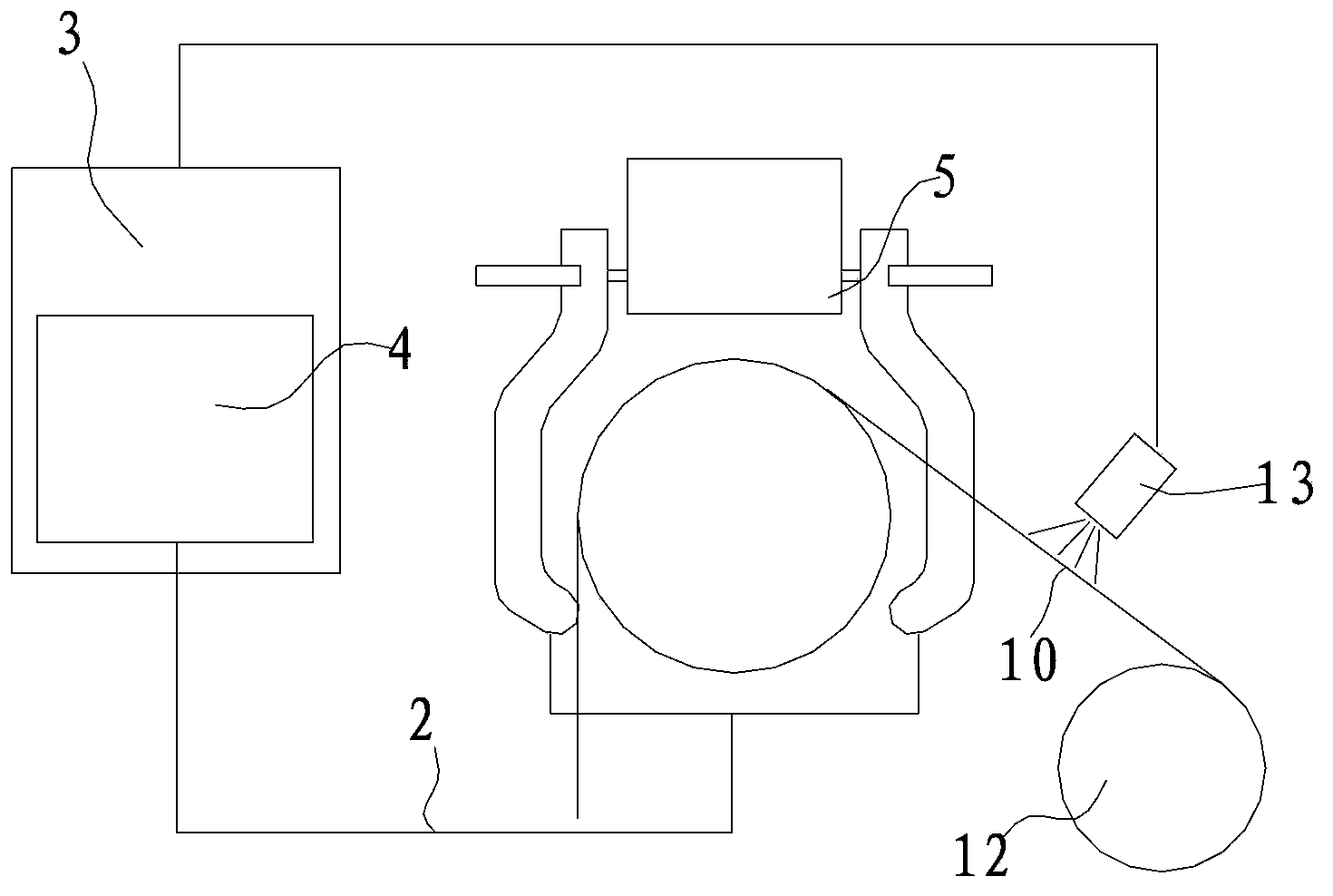

[0027] Such as figure 1 As shown, the traction wire rope broken strand detection device includes an elevator control cabinet 3 fixed in the machine room, a microcomputer circuit board 4 installed in the elevator control cabinet 3, a traction machine 5 fixed on the frame beam, and a The rope end spring 6 on the 8, the pressure sensor 7, the rope end wedge sleeve assembly 9, the steel wire rope 10 that is fixed on the rope end wedge sleeve assembly 9. The pressure sensor 7 is arranged between the rope head spring 6 and the mounting plate 8, and is used to detect the tension of the wire rope. The pressure sensor 7 is connected to the microcomputer circuit board 4 through the control line 1, and the detected wire rope tension signal is fed back to the Processing in the microcomputer circuit board 4, when the value of the same steel wire rope back-test tension is greater than or equal to 50% than the front-test tension reduction, it is judged that the steel wire rope is a broken s...

Embodiment 2

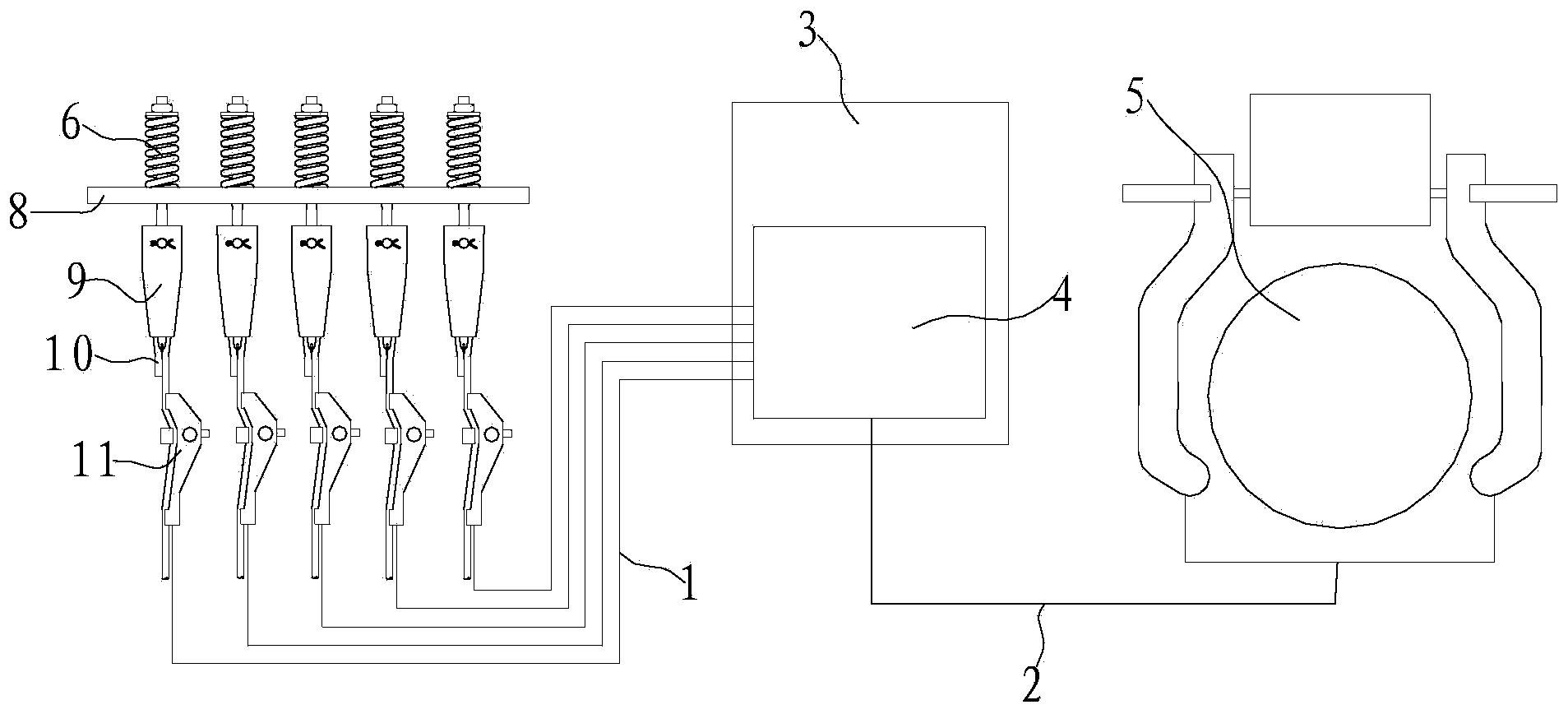

[0030] Such as figure 2 As shown, the traction wire rope broken strand detection device includes an elevator control cabinet 3 fixed in the machine room, a microcomputer circuit board 4 installed in the elevator control cabinet 3, a traction machine 5 fixed on the frame beam, and a Rope end spring 6 on 8, tensiometer 11, rope end wedge sleeve assembly 9, the steel wire rope 10 that is fixed on the rope end wedge sleeve assembly 9. The tensiometer 11 is fixed on the wire rope 10 for detecting the tension of the wire rope. The tensiometer 11 is connected to the microcomputer circuit board 4 through the control line 1, and the detected steel wire rope tension signal is fed back to the microcomputer circuit board 4 for processing. If it is greater than or equal to 50%, it is judged that the wire rope is broken.

[0031] The concrete operation process is as follows: the wire rope tensiometer 11 fixed on the wire rope 10 continuously feeds back the tension of each wire rope 10 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com