Combined crane for docks and dock wharfs

A crane and combined technology, applied in the directions of walking bridge cranes, cranes, transportation and packaging, can solve problems such as poor equipment stability, increased basic investment, large safety distance, etc., to facilitate unified operation and improve overall stability. The effect of saving basic investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

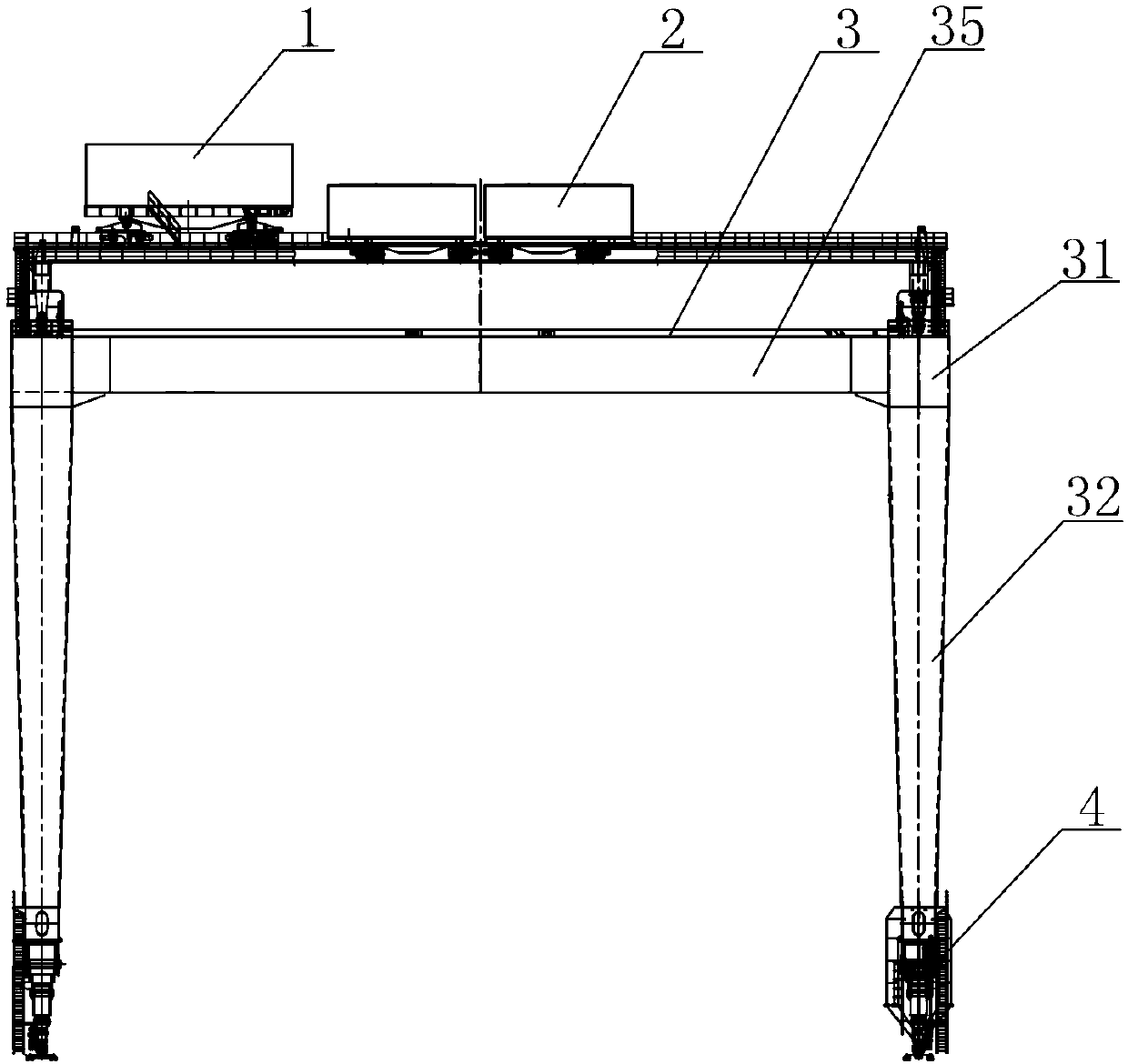

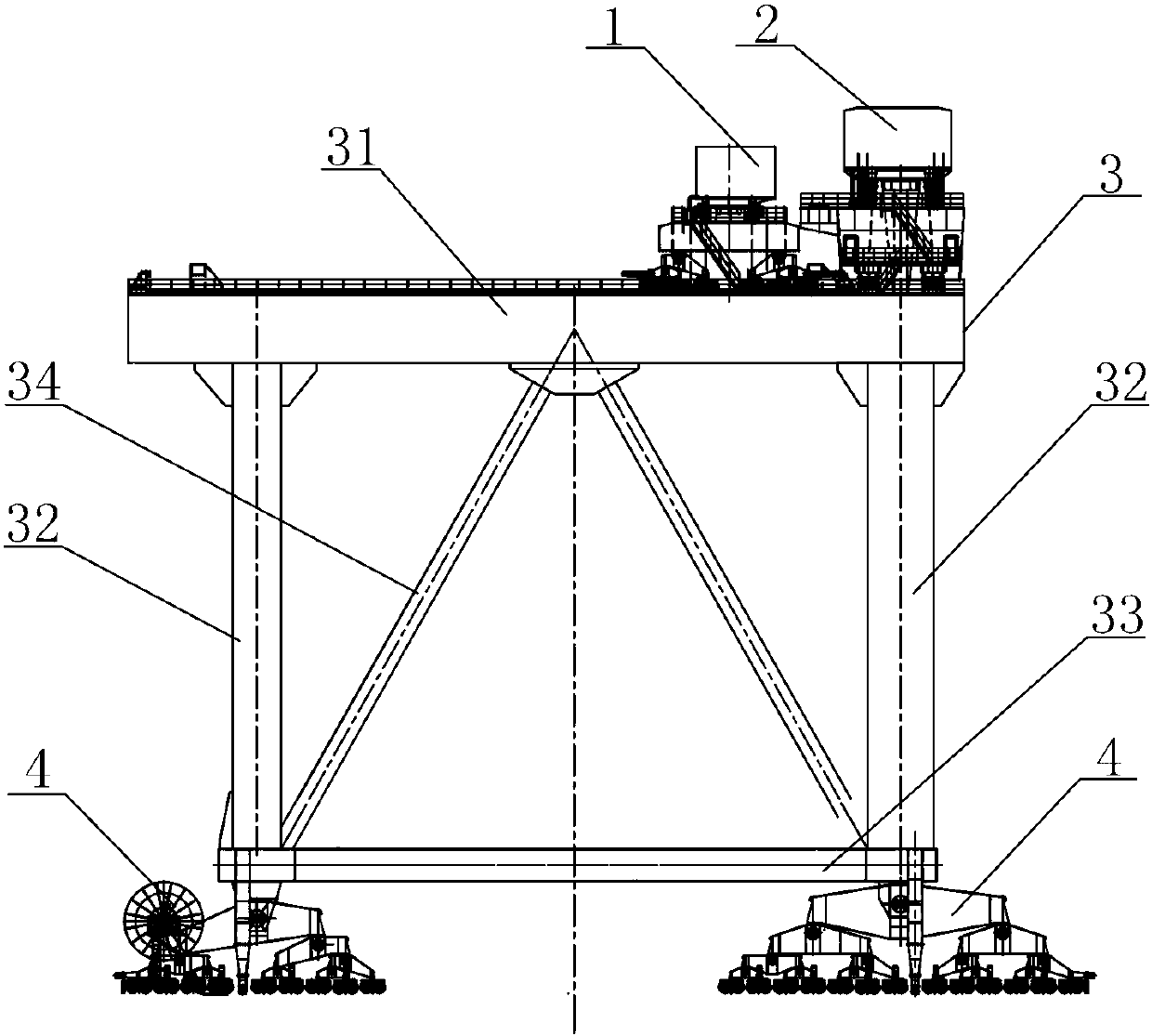

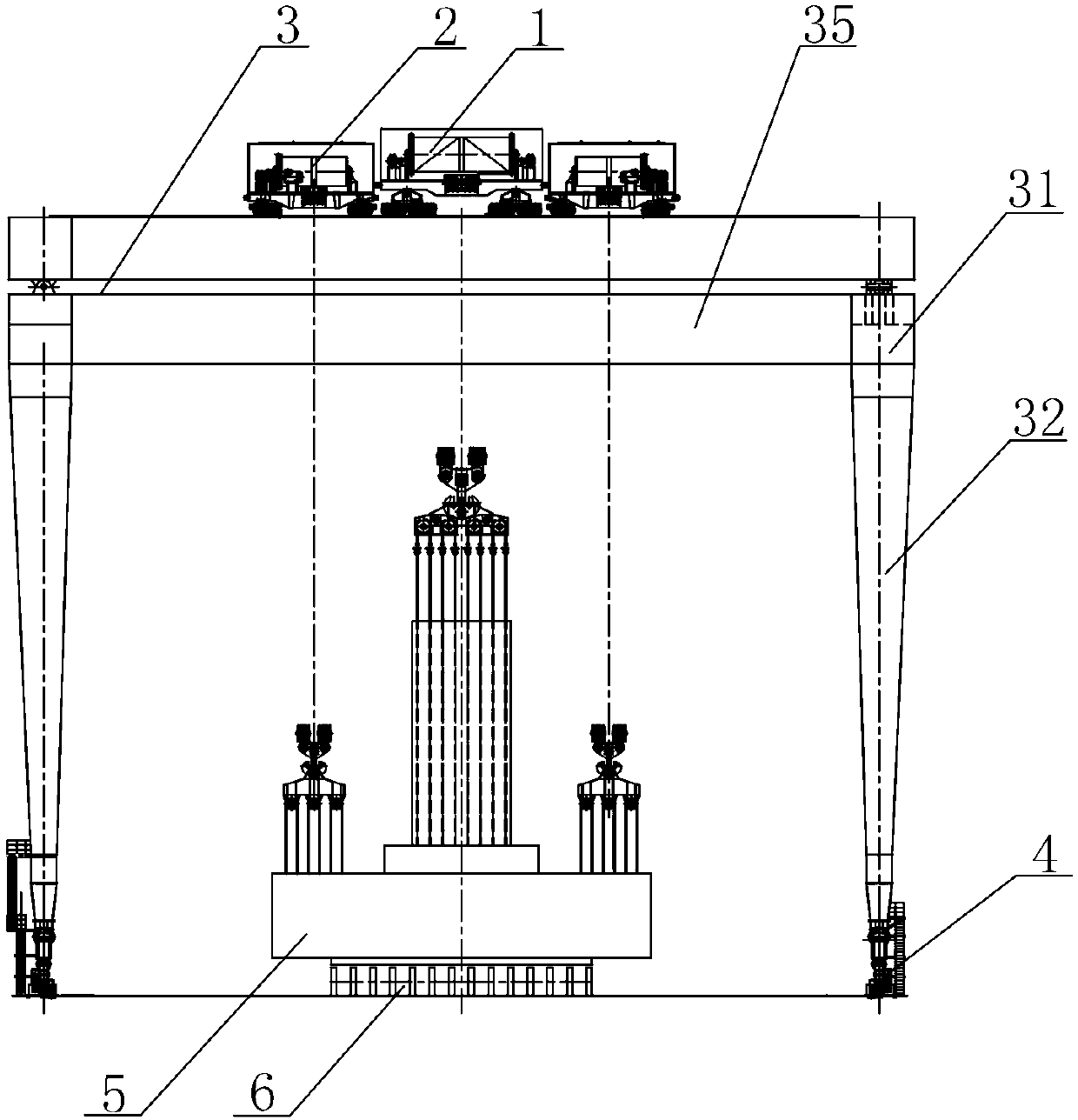

[0010] See attached Figure 1~Figure 2 , the present invention consists of a single-car fixed bridge crane 1, a double-car movable bridge crane 2, a frame structure 3 and a complete machine operating mechanism 4, and the single-car fixed bridge crane 1 and the double-car movable bridge crane 2 are combined. On the movable frame structure 3; the frame structure 3 is welded by track beam 31, column leg 32, lower beam 33, oblique support 34 and connection beam 35, track beam 31 and lower beam 33 are connected with two column legs 32 The side frame is formed by welding, and the diagonal support 34 is fixedly arranged between the track beam 31 and the lower beam 33 in a triangle, and the two side frames are welded by two connecting beams 35 to form a door frame steel structure; the single trolley fixed bridge crane 1 is formed by a plane hinge Or the plate hinge is fixedly arranged on the two rail beams 31; the movable bridge crane 2 with double trolleys is arranged on the two rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com