Preparation method of steaming-resisting and boiling-resisting poly(vinylidene chloride) (PVDC) waterborne emulsion

A water-based emulsion, retort-resistant technology, used in flexible coverings, coatings, packaging, etc., can solve problems such as limited shelf life, reduced barrier properties, and poor transparency, achieve low film-forming temperature and heat-sealing temperature, improve Film-forming and heat-sealing properties, and the effect of ensuring barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method for retort-resistant PVDC aqueous emulsion, comprising the steps of:

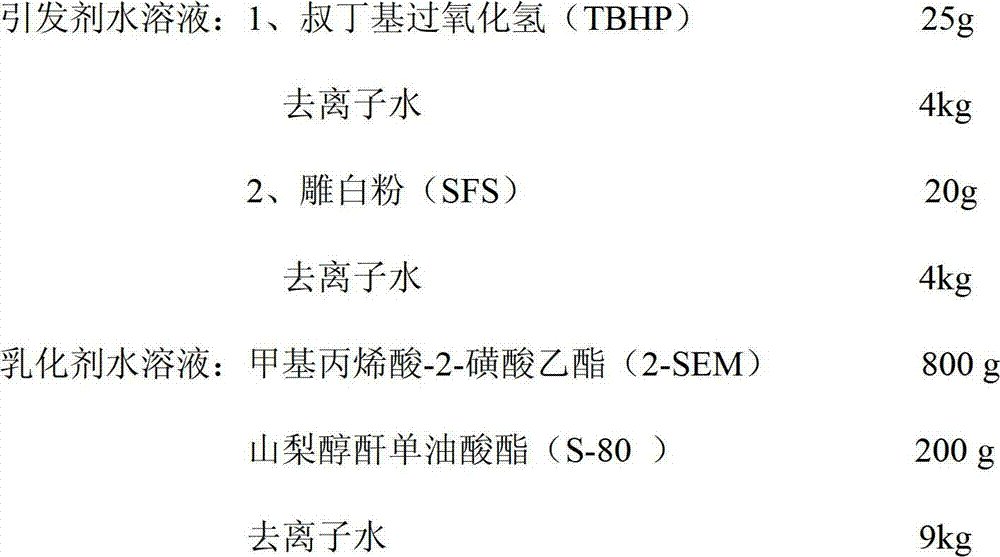

[0033] (1) Based on 100 parts of mixed monomers, prepare an aqueous solution of initiator and emulsifier according to the following formula:

[0034]

[0035] (2) Put 38kg of deionized water, 80g of sodium lauryl sulfate, and 20g of glacial acetic acid into a 100L stainless steel polymerization kettle (length-to-diameter ratio of 2:1, double-layer and two-leaf 45° inclined propeller), and test the pressure with nitrogen Vacuum after leak testing.

[0036] (3) Add 3.3kg of vinylidene chloride and 0.28kg of methyl acrylate into the polymerization kettle, stir for 20 minutes, then raise the temperature to 55°C, add 0.25kg of tert-butyl hydrogen peroxide aqueous solution and 0.24kg of diaoba powder aqueous solution dropwise, drop The reaction was added for 1 hour to complete the seed polymerization.

[0037] (4) Continuously drop 22.6kg of vinylidene chloride, 2.1kg of methyl ac...

Embodiment 2

[0042] A preparation method for retort-resistant PVDC aqueous emulsion, comprising the steps of:

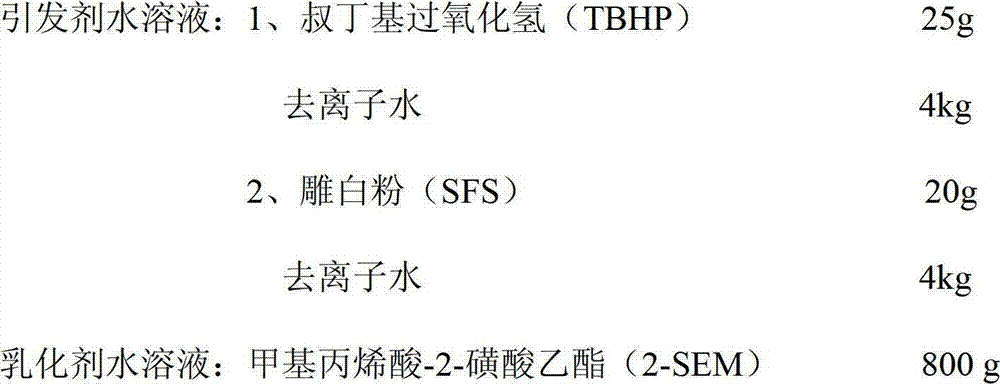

[0043](1) Based on 100 parts of mixed monomers, prepare an aqueous solution of initiator and emulsifier according to the following formula:

[0044]

[0045]

[0046] (2) Put 38kg of deionized water, 135g of sodium lauryl sulfate, and 25g of potassium bicarbonate into a 100L stainless steel polymerization kettle (length-to-diameter ratio of 2:1, double-layer and two-leaf 45° oblique propeller), and test with nitrogen Vacuum after leak test.

[0047] (3) Add 1.96kg of vinylidene chloride and 0.3kg of methyl acrylate into the polymerization kettle, stir for 22 minutes, then raise the temperature to 57°C, add 0.20kg of tert-butyl hydrogen peroxide aqueous solution and 0.20kg of diaoba powder aqueous solution dropwise, drop The reaction was added for 0.5 hours to complete the seed polymerization.

[0048] (4) Continuously drop 17.15kg of vinylidene chloride, 1.4kg of methyl a...

Embodiment 3

[0053] A preparation method for retort-resistant PVDC aqueous emulsion, comprising the steps of:

[0054] (1) Based on 100 parts of mixed monomers, prepare an aqueous solution of initiator and emulsifier according to the following formula:

[0055]

[0056]

[0057] (2) Put 38kg of deionized water, 60g of sodium lauryl sulfate, and 12g of glacial acetic acid into a 100L stainless steel polymerization kettle (length-to-diameter ratio of 2:1, double-layer and two-leaf 45° inclined propeller), and test the pressure with nitrogen Vacuum after leak testing.

[0058] (3) Add 2.52kg of vinylidene chloride and 0.28kg of methyl acrylate into the polymerization kettle, stir for 25 minutes, then raise the temperature to 55°C, add 0.28kg of tert-butyl hydrogen peroxide aqueous solution and 0.27kg of diabolite aqueous solution dropwise, drop The reaction was added for 1.5 hours to complete the seed polymerization.

[0059] (4) Continuously drop 30.18kg of vinylidene chloride, 1.4kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com