Boiling-resistant PVDC (polyvinyl dichloride) water-based emulsion

A water-based emulsion, retort-resistant technology, applied in coatings and other directions, can solve the problems of invisible packaging, food not sterilized at high temperature, limited shelf life, etc., and achieve good anti-boiled "whitening effect"

Active Publication Date: 2015-04-01

ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +1

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] 1. The packaged food provided needs to be cooked and processed by consumers before they can be eaten, which is a waste of time;

[0004] 2. The food provided has not been sterilized by high temperature and has a limited shelf life;

[0005] 3. The packaging is opaque, and the packaged objects cannot be seen

The disadvantage is that this method uses a commercially available general-purpose PVDC emulsion to make a retort-resistant PVDC water-based emulsion coating film, but the PVDC emulsion coating film made of a general-purpose PVDC emulsion is foggy and "whitened" during boiling. ", the barrier property decreases, the transparency becomes poor, which affects the appearance and performance of packaging products

Therefore, commercially available general-purpose PVDC emulsions still have certain defects in the application of boiled food packaging.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

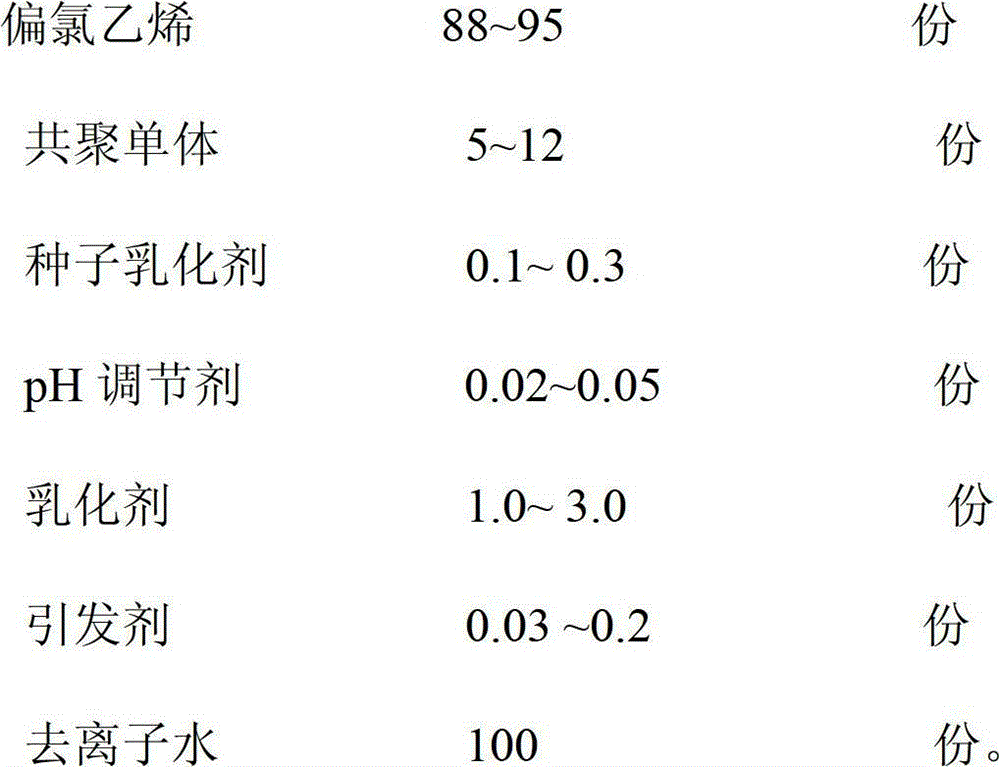

[0029] A kind of retort resistant PVDC aqueous emulsion, its raw material formula is as follows:

[0030]

[0031]

Embodiment 2

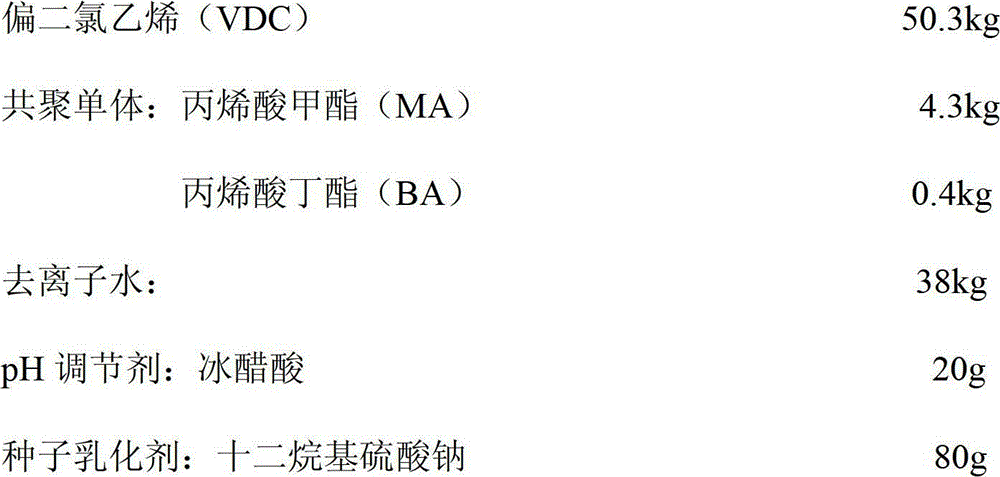

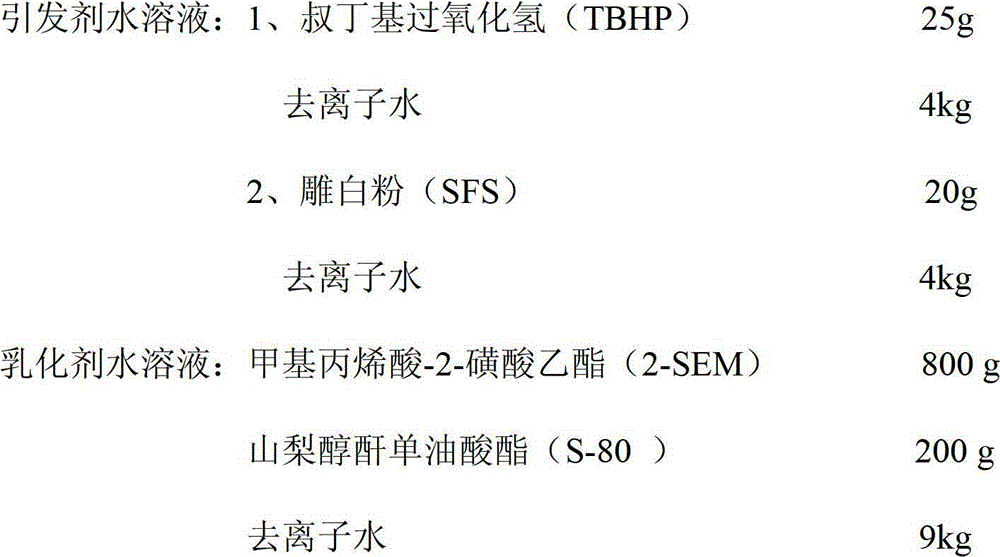

[0033] A kind of retort resistant PVDC aqueous emulsion, its raw material formula is as follows:

[0034]

Embodiment 3

[0036] A kind of retort resistant PVDC aqueous emulsion, its raw material formula is as follows:

[0037]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a boiling-resistant PVDC (polyvinyl dichloride) water-based emulsion which is composed of the following components in parts by weight: 88-95 parts of vinylidene chloride, 5-12 parts of comonomer, 0.10-0.3 part of seed emulsifier, 0.02-0.05 part of pH regulator, 1.0-3.0 parts of emulsifier, 0.03-0.2 part of initiator and 100 parts of deionized water. The boiling-resistant PVDC water-based emulsion disclosed by the invention is suitable for coating a biaxially-oriented nylon film; the formed film has favorable obstruction property; the prepared coated film has favorable boiling whitening resistance; and the boiled coated film has transparent appearance, and can be widely used in packaging materials for boiling-sterilized foods, such as fruits and vegetables.

Description

technical field [0001] The invention relates to a PVDC copolymer emulsion, more specifically, the invention relates to a retort-resistant PVDC aqueous emulsion. Background technique [0002] Polyvinylidene chloride (PVDC) polymer material, as a packaging material with good comprehensive barrier properties, is safe and non-toxic, and has a wide range of applications in the field of food packaging. The application technology of general-purpose PVDC emulsion in food coating film BOPP and BOPET film is mature. However, there are following deficiencies in the packaging of exported boiled fruits and vegetables: [0003] 1. The packaged food provided needs to be cooked and processed by consumers before they can be eaten, which is a waste of time; [0004] 2. The food provided has not been sterilized by high temperature and has a limited shelf life; [0005] 3. The packaging is opaque, and the packaged objects cannot be seen. [0006] In response to the above shortcomings, peopl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F214/08C08F220/14C08F220/18C08F220/28C08F218/08C08F220/44C08F220/42C08F220/06C08F222/02C08F2/26C08F2/30C08F2/38C08F4/40C09D127/08

Inventor 韩金铭吴宇鹏邓建明苏兰辉祝龙信吴志刚吴学红郑向军吕颖琦

Owner ZHEJIANG QUZHOU JUSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com