Dedicated electrolysis and ultrasonic cleaning integrated equipment for machining parts

A mechanical processing and ultrasonic technology, applied in the electrolysis process, electrolysis components, cleaning methods using liquids, etc., can solve the problems of low efficiency, increase the cost of parts processing, shorten the processing time of parts, etc., to achieve convenient cleaning, improve production efficiency, Simple and practical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

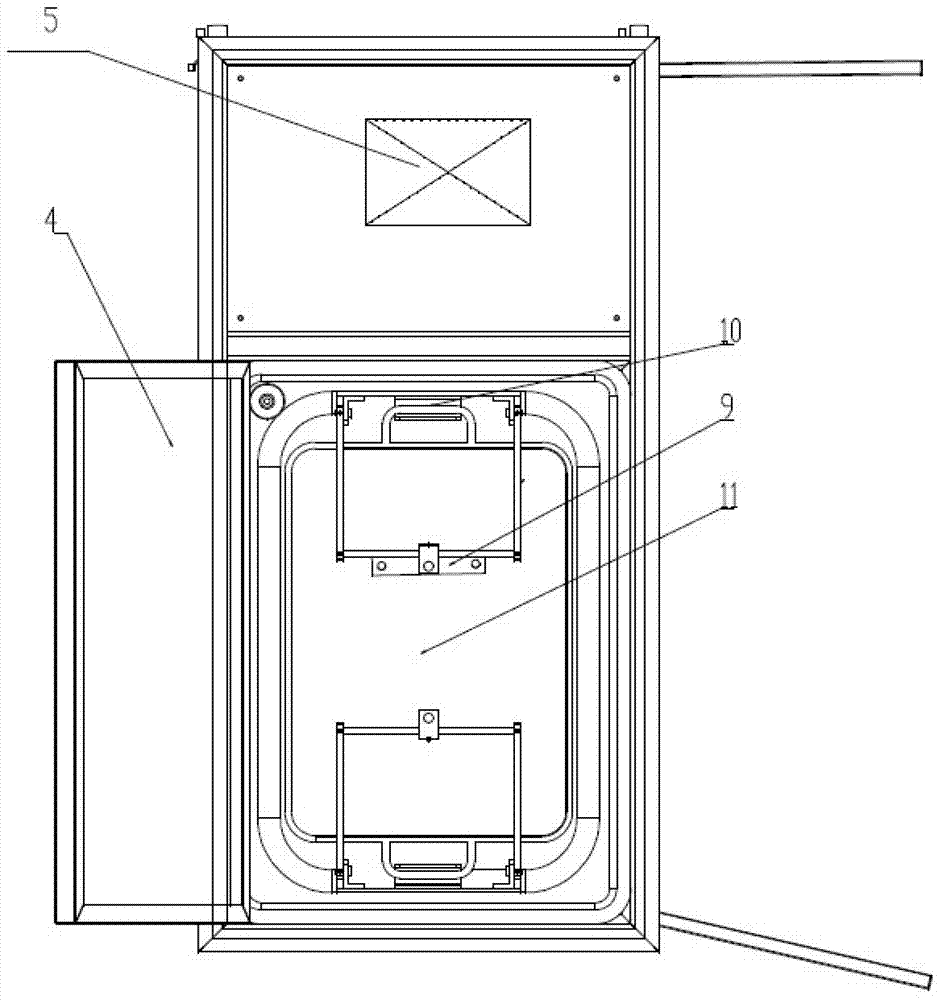

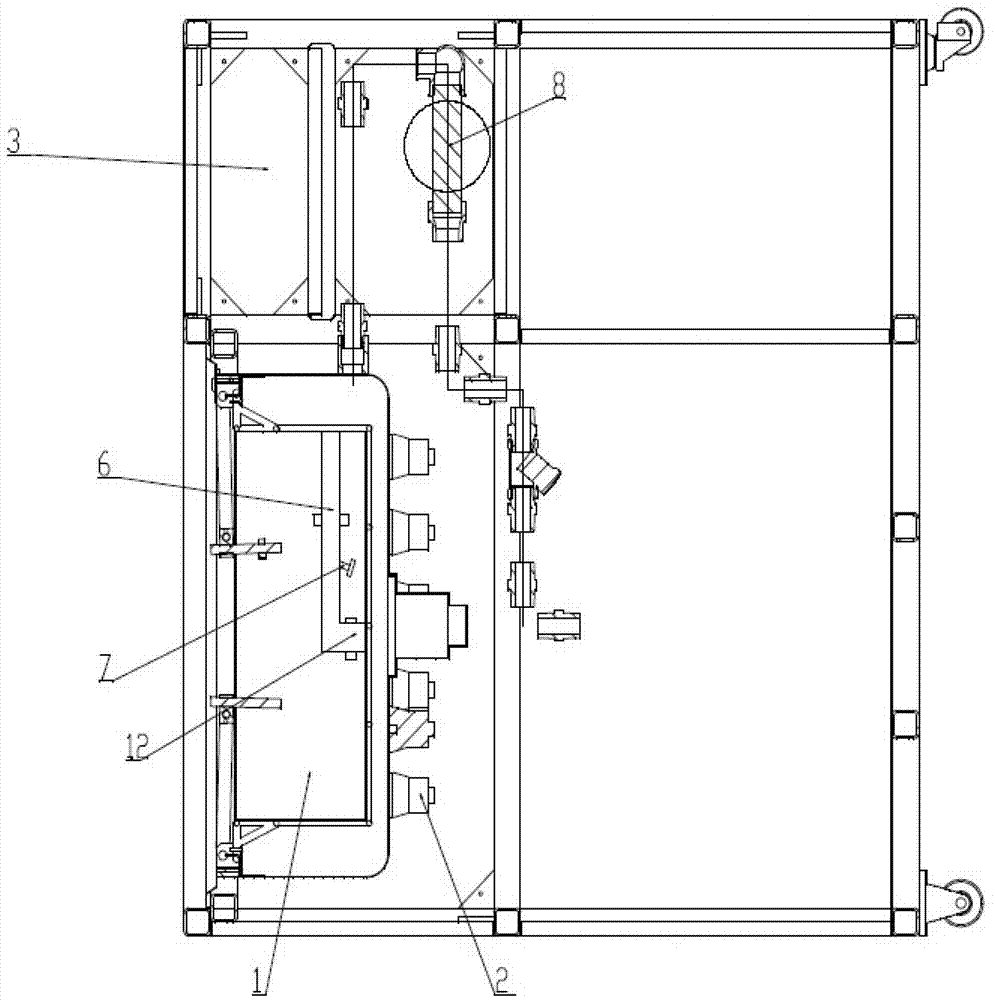

[0016] Such as Figure 1-2 As shown, the integrated electrolysis and ultrasonic cleaning equipment for machined parts includes a cleaning tank 1 filled with electrolyte, and an ultrasonic vibrator 2 is installed on the cleaning tank 1. The ultrasonic vibrator 2 performs cleaning work under the action of the ultrasonic generator 3; The cover plate 4 seals the cleaning water tank 1, and the vacuum air pump 5 vacuumizes the space sealed by the cover plate; the circulating water pipe 6 is installed in the cleaning water tank 1, and the filter 7 on the circulating water pipe 6 is continuously cleaned The electrolyte in the water tank 1 is circulated and filtered; the positive and negative electrodes 9 and 10 for electrolysis are also arranged in the cleaning water tank 1 , and the machined parts are placed in the storage basket 11 in the cleaning water tank 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com