U-bar isolation anti-buckling energy dissipation support

A technology of anti-buckling energy consumption and channel steel, applied in the direction of earthquake resistance, building components, etc., can solve the problems of loss of restraint and anti-buckling effect, energy consumption capacity reduction, etc., to reduce earthquake response, improve energy consumption capacity, and good seismic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

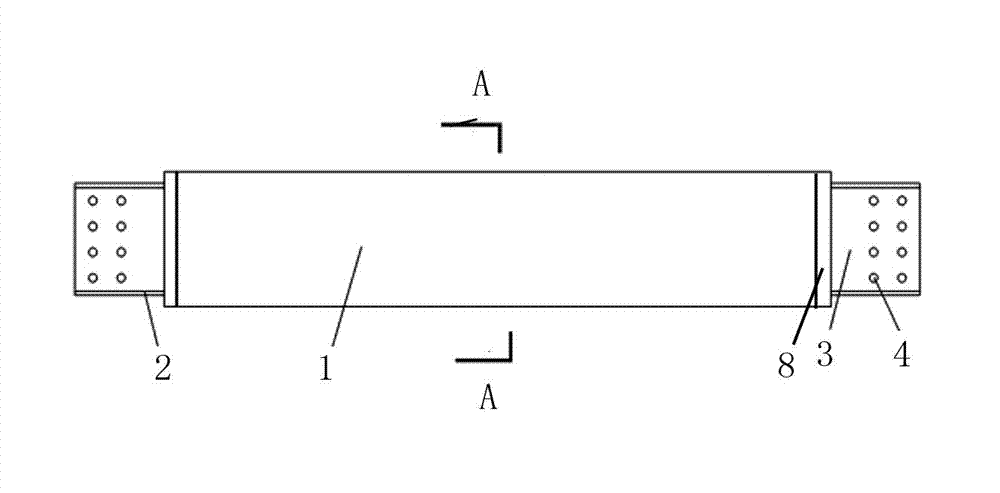

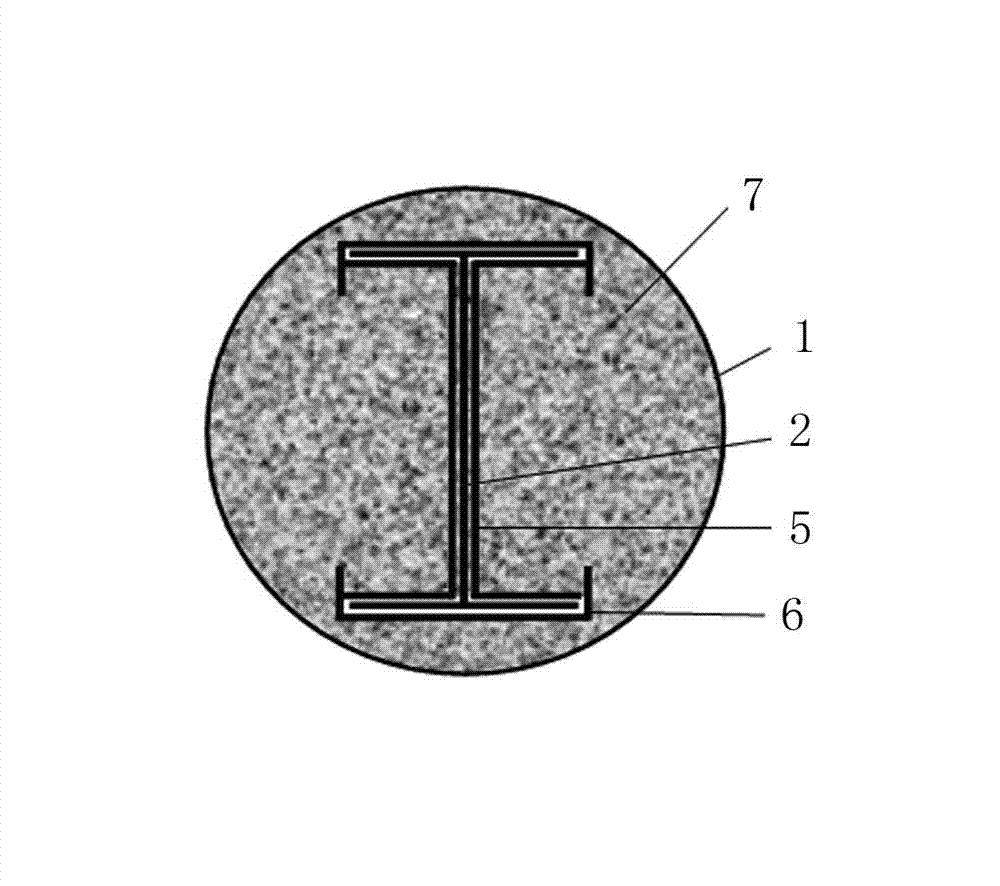

[0022] like figure 1 , 2 . The channel-steel isolated anti-buckling energy-dissipating support shown in 4 includes: constrained round steel pipe 1, energy-dissipating I-steel 2 and isolated channel steel, and both ends of constrained round steel pipe 1 are provided with energy-dissipating I-steel 2; One end of the energy-dissipating I-beam 2 is set in the constrained circular steel pipe 1, and side isolation channel steel 5 is provided on both sides of the web of the energy-dissipating I-beam at this end; There is an outer isolated channel steel 6; the other end of the energy-dissipating I-beam 2 is located outside the constrained round steel pipe 1, and both sides of the web of the energy-dissipating I-beam 2 are fixedly connected with reinforced steel plates 3; Both ends of the constrained round steel pipe 1 are provided with end plates 8; inner filling constrained concrete 7 is poured between the inner side of the end plate 8 and the constrained round steel pipe 1. Bolt h...

Embodiment 2

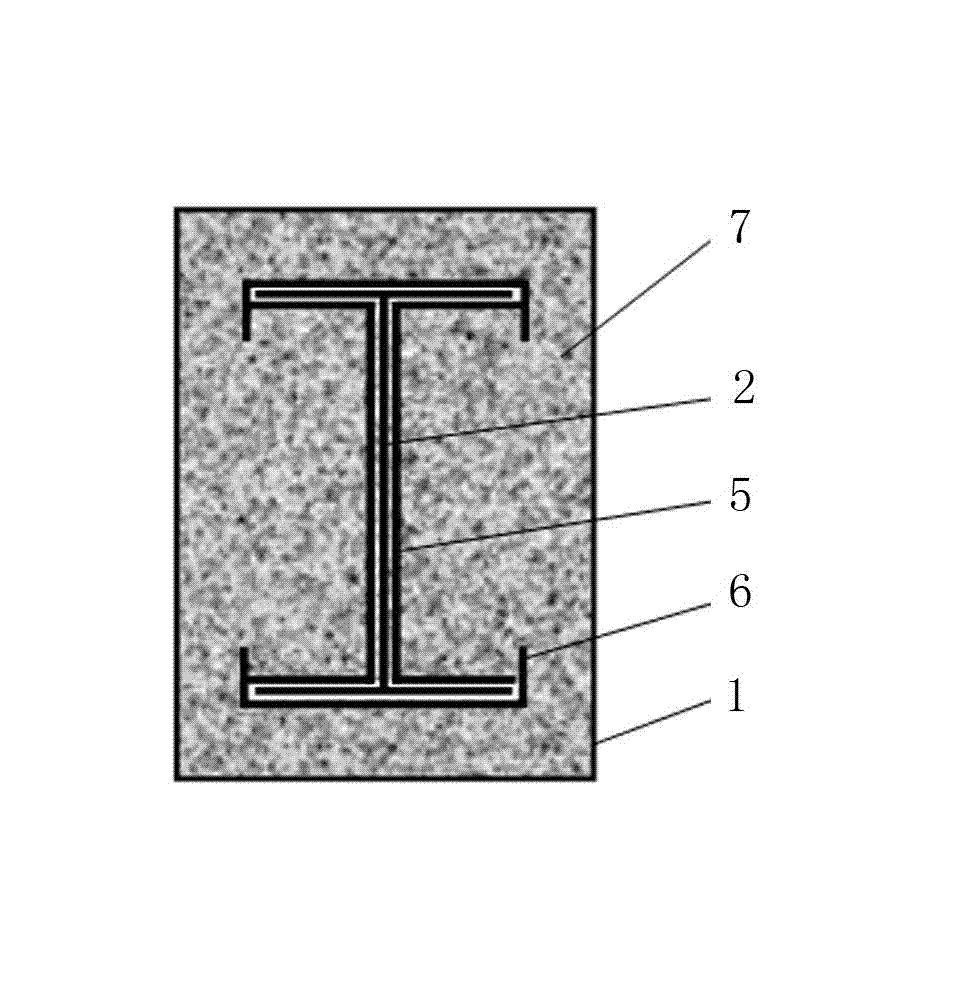

[0024] like figure 1 , 3 The channel steel isolated anti-buckling energy dissipation support shown in 5 includes: a constrained square steel pipe 1, an energy dissipative I-beam 2 and an isolated channel steel, and both ends of the constrained square steel pipe 1 are provided with an energy dissipative I-beam 2; One end of the energy-dissipating I-beam 2 is set in the restraining square steel pipe 1, and side isolation channel steel 5 is provided on both sides of the web of the energy-dissipating I-beam at this end; There is an outer isolation channel steel 6; the other end of the energy-dissipating I-beam 2 is located outside the restraining square steel pipe 1, and the two sides of the web of the energy-dissipating I-beam 2 at this end are fixedly connected with reinforced steel plates 3; Both ends of the constrained square steel pipe 1 are provided with end plates 8; inner filling constrained concrete 7 is poured between the inner side of the end plate 8 and the constraine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com