Connecting bolt enabling screw to be mounted afterwards and using method of connecting bolt

A technology for connecting bolts and screws, which is applied in the direction of connecting components, screws, threaded fasteners, etc., can solve the problems of not allowing large deformation, fastening difficult objects, and no operating space on the opposite side, so as to achieve simplification Fastening method, the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

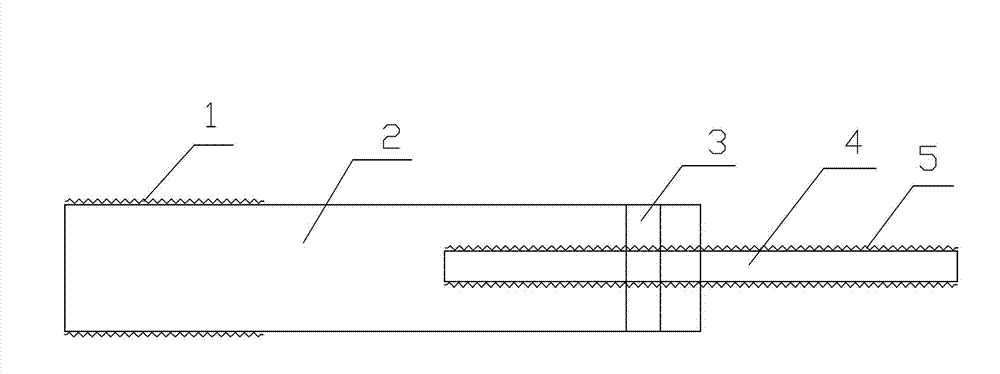

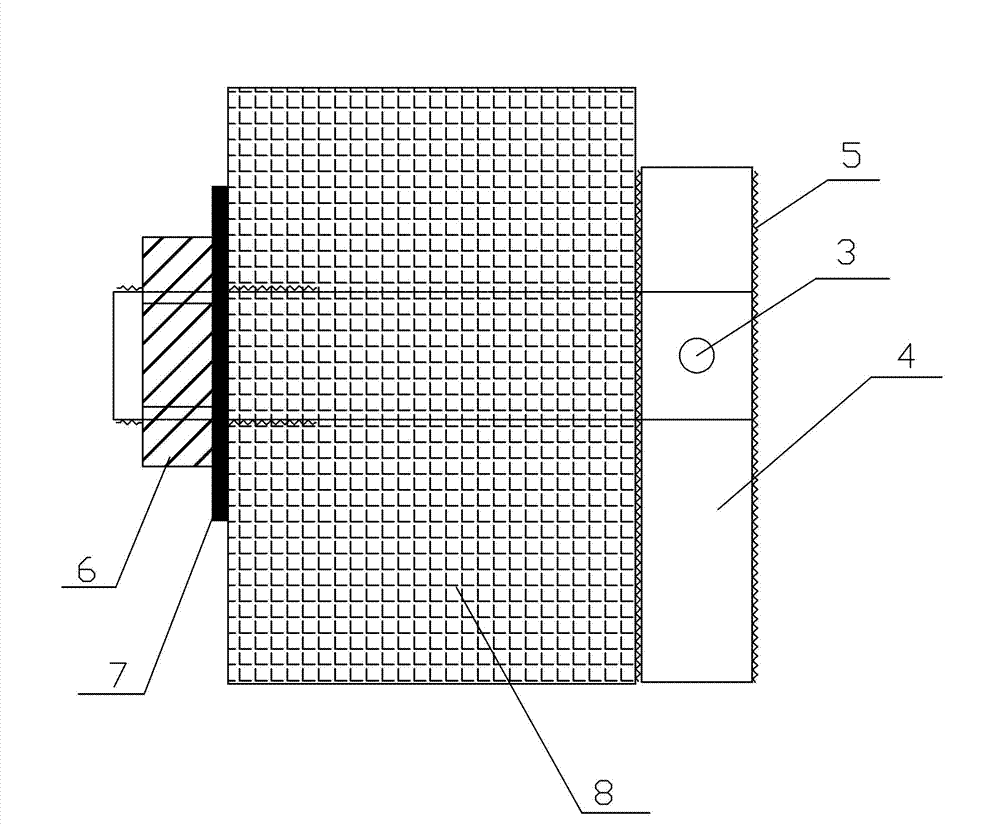

[0021] combine figure 1 and figure 2 , a connecting bolt capable of post-installing a screw rod, comprising a screw rod 2 and a rectangular bar 4 . One end of the screw is provided with a thread 1, and the other end is provided with a through notch, and the through notch extends to the end of the screw along the direction of the axis of the screw. The above-mentioned rectangular bar can be composed of four rectangular sides and two rectangular end faces, wherein the four rectangular sides include two larger rectangular sides and two smaller rectangular sides, and the rectangular bar passes through the pin shaft 3 located in the through notch. The pin is connected to the screw, the axis of the pin shaft is perpendicular to the axis of the screw rod, the geometric center of the rectangular bar and the pin shaft does not coincide, so that the bars on both sides of the rectangular bar are of different weights, and all or A part can be put into the through slot, and the rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com