A zero-backlash planetary transmission reduction device

A technology of reduction gear and gap planet, which is applied in the direction of transmission, transmission parts, gear transmission, etc. It can solve the problems of long processing cycle time, increased clearance between planetary gear and pin shaft, and unable to solve the problem of large backlash. , to achieve the effect of eliminating system backlash and realizing operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

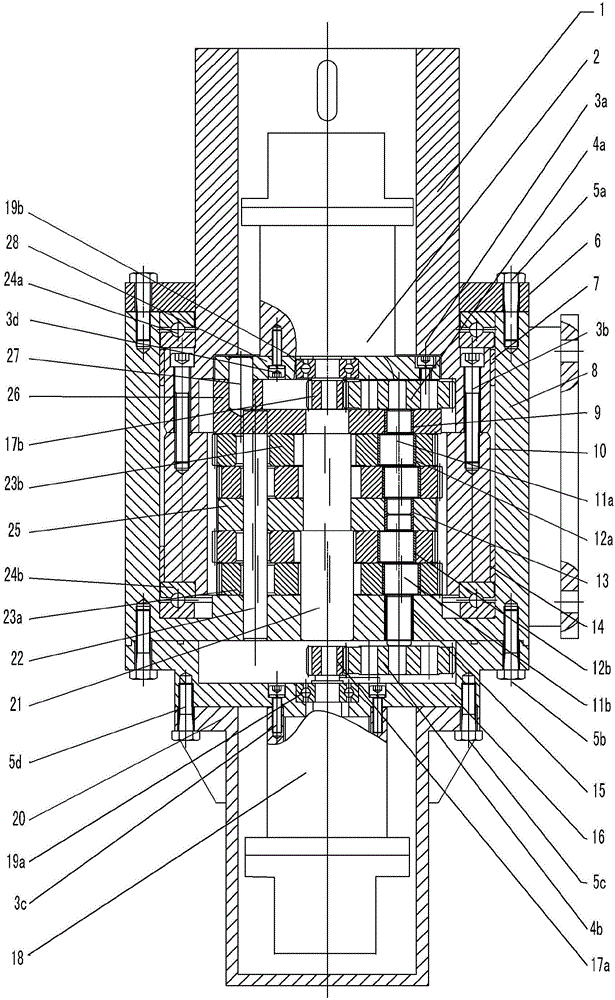

[0036] see figure 1 , This embodiment is a zero-backlash deceleration device for an automatic solar tracking system.

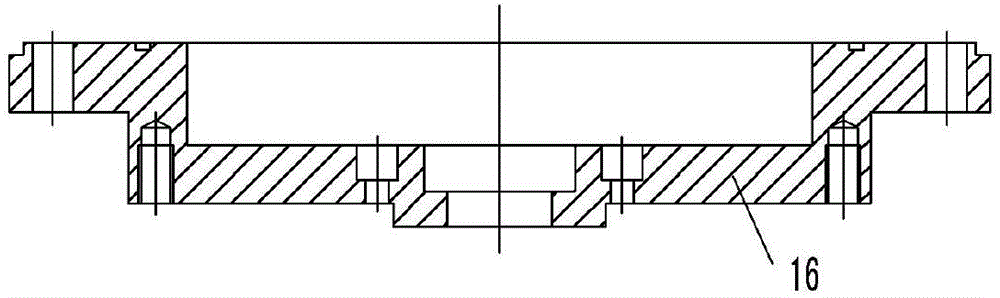

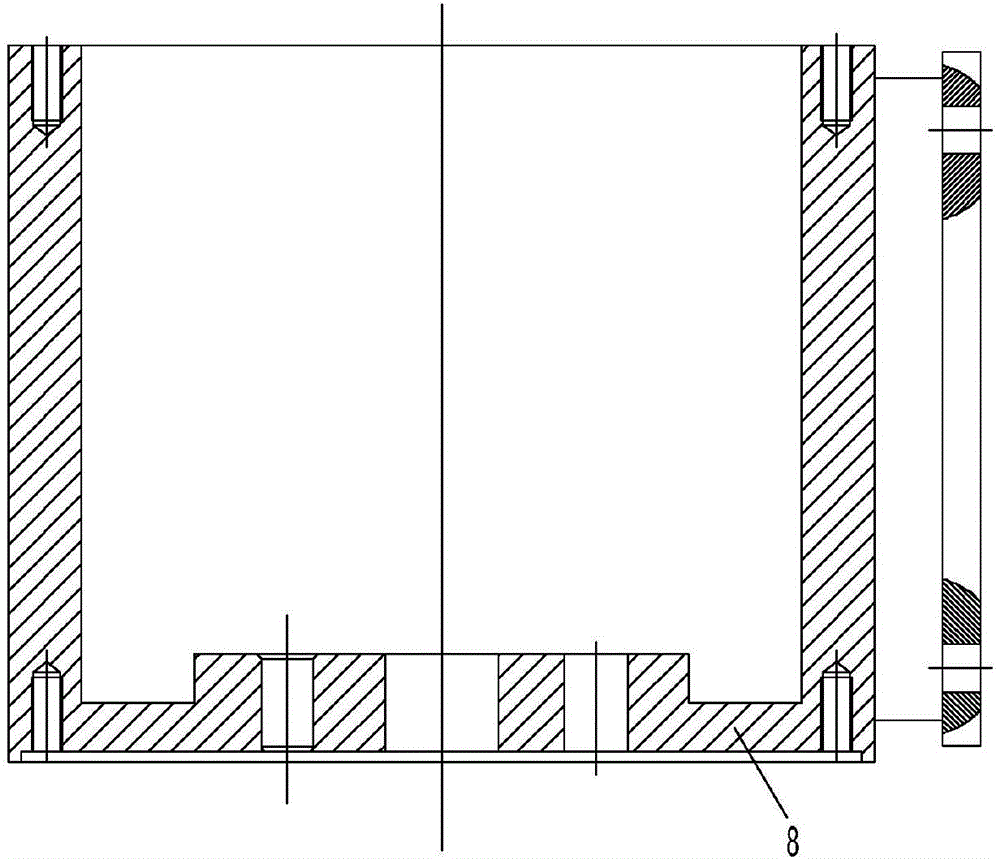

[0037] Zero-backlash planetary transmission reduction device of the present invention, output shaft 1 (see Image 6 ) is fixed on the inner ring gear 10 by the second hexagon socket head cap screw 3b, and the lower end surface of the inner ring gear 10 is provided with a lower plane bearing 24b (see Figure 15 ), the outer step end surface of the output shaft 1 is provided with an upper plane bearing 24a, and the centering bearing 7 and the ring gear centering bearing 14 are respectively installed at the upper end and the lower end of the inner hole of the ring gear seat 8; the output shaft gland 6 (see Figure 4 ) is fixed on the open end of the ring gear seat 8 by the first outer hexagonal bolt 5a; two reduction mechanisms driven by the upper motor 2 and the lower motor 18 are provided, and the upper inner rotor 23b and the lower inner rotor 23a (see Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com