Device for quickly centering and clamping motors during test

A fast, motor-loaded technology, used in motor generator testing, measuring device casings, etc., can solve the problems of occupying human resources, high error probability, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

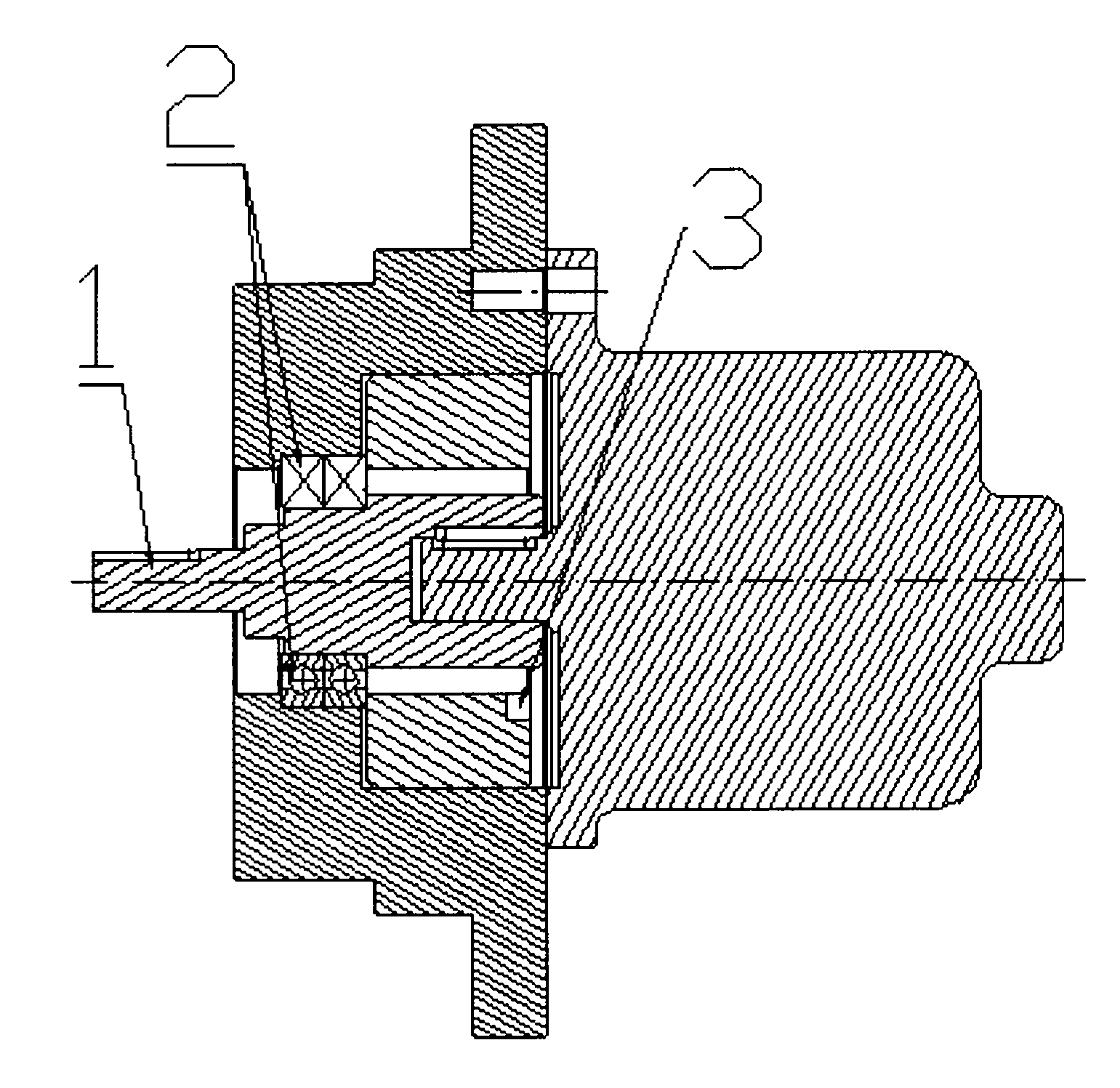

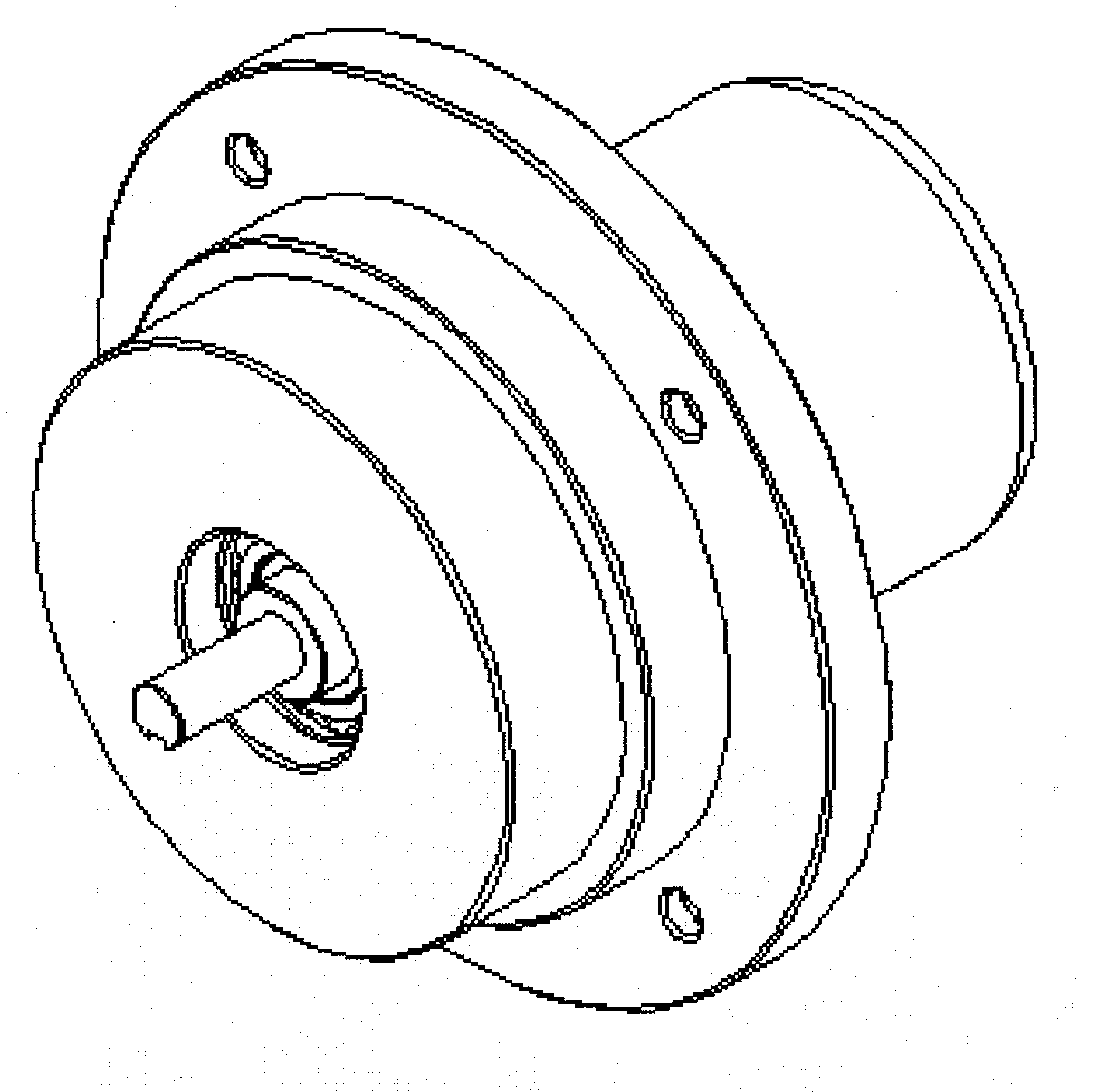

[0004] The invention is mainly composed of three parts: a centering box body, a flange plate and a torque sensor seat.

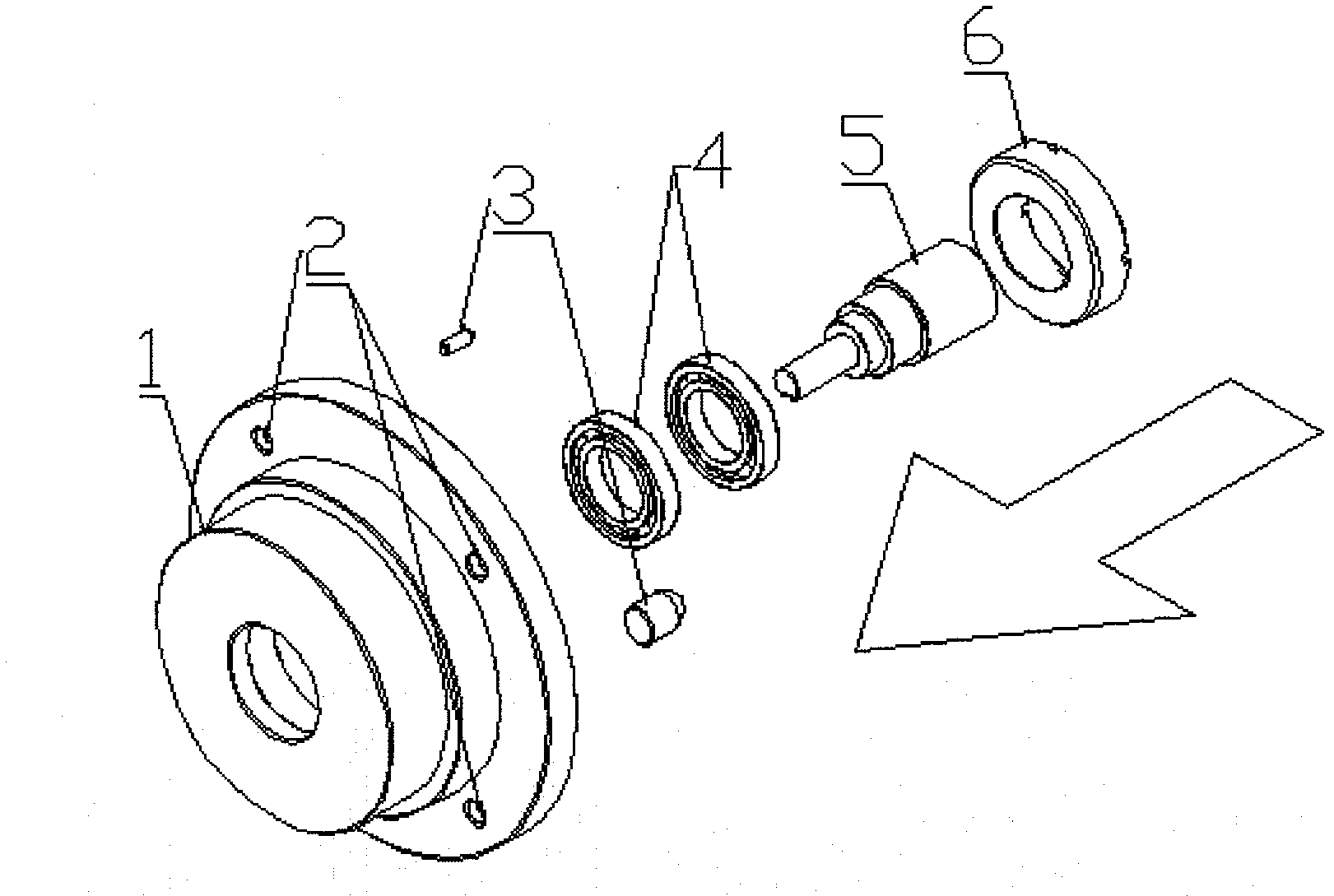

[0005] Flange: It is mainly composed of five parts: disc base, positioning pin, bearing, transmission shaft and motor positioning disc. Such as figure 1 (1), when processing the flange, take the bottom of the box as the rough reference, make a tubular protrusion parallel to the bottom and install the motor plane vertically. This part is used for the preliminary positioning of the motor and facilitates subsequent installation, which is the disc-shaped base. The tubular protruding part in front of the base is prepared for the pre-installation when the flange and the box are docked, so that the flange can be temporarily suspended on the box when the screws are not tightened to save manpower, and at the same time provide a rough alignment Connection benchmarks. Such as figure 1 (2), 4 screw holes are used to connect and fix the centering box. When the flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com