Washing machine detergent remaining quantity detection and display method

A display method and detergent technology, which is applied to other washing machines, washing devices, buoy liquid level indicators, etc., can solve the problem of not being able to visually check the real-time remaining amount of detergent, not considering the viscosity of detergent, and being unable to do a good job Liquid addition preparation and other issues to achieve the effect of overcoming adverse effects, intuitive display, and easy replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

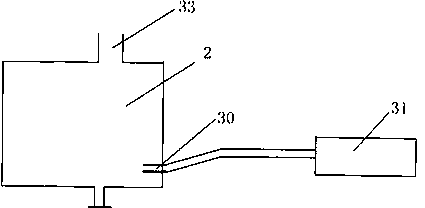

[0019] figure 1 What is shown is a structural schematic diagram of an existing two conductive metal probes used as a warning for insufficient margin. As shown in the figure, at the bottom of the detergent box 2, two non-contact metal probes 30 are set. When the probes 30 are immersed in the detergent, the conduction is transmitted to the processor as a logical information with a margin. The washing machine can work normally; when the detergent is insufficient, the disconnection of the metal probe is sent to the processor 31 as a message of insufficient surplus, and an alarm for insufficient surplus is performed. This method is obviously simple and extensive, there are only "yes" or "no", and it is impossible to realize the real-time display of the remaining amount, and, once the metal probe is stuck by the viscous detergent, it will generate wrong signals and affect the washing effect (no washing action with detergent), wasting energy.

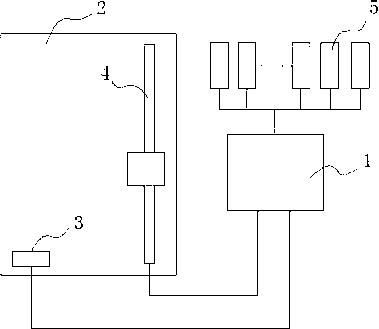

[0020] The system structure of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com