Application of wire guide device in elasticizers, and efficient and energy-saving elasticizer

A high-efficiency, energy-saving, yarn guide technology, applied in textiles and papermaking, can solve the problems of increased temperature, large consumption of energy-consuming rollers in transmission, and decreased crimp rate of finished fibers, so as to improve the efficiency of texturing, save energy, and improve overall efficiency. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

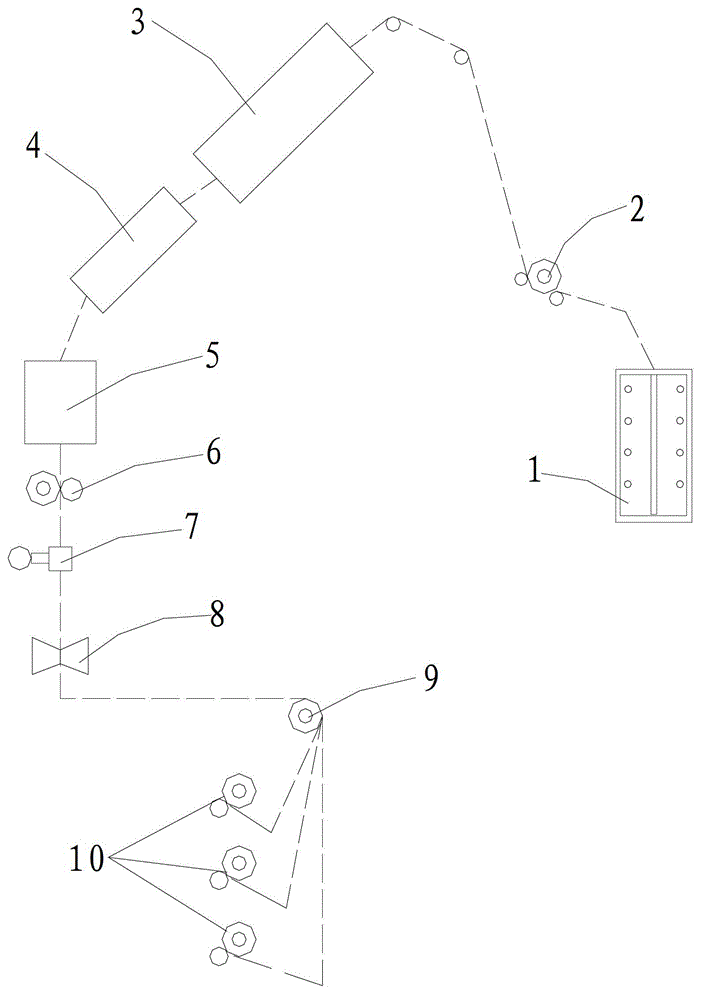

[0040] Please also refer to figure 1 , the main purpose of the present invention is to apply the wire guide 8 on the texturing machine, especially the wire guide 8 replaces the third roller of the original texturing machine, and the wire guide 8 is arranged on the second roller 6 and the winding mechanism In between, the second roller 6 is located above the yarn guide 8, and a network nozzle 7 is arranged between the middle roller and the yarn guide 8. General yarn guide 8 can be used, in order to improve efficiency, yarn guide 8 of the present invention adopts wire guide wheel, is installed in the top roller position of former 3rd roller, and is provided with between the transmission shaft of former 3rd roller spacing. Through this desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com