Mine wellhead crossover combined turnout junction

A technology for turnouts and mines, which is applied to the field of combined turnouts for mine wellhead crossing lines, can solve the problems of high labor intensity, low production efficiency, and high misfeeding rate of workers, and achieve the effects of saving manpower, easy operation and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

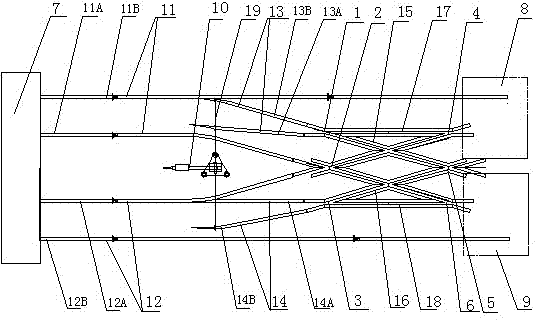

[0012] Such as figure 1 As shown, a mine wellhead crossing combination turnout includes No. 1 rail 11 and No. 2 rail 12 connected to the wellhead platform 7, and also includes No. 1 switch rail 13, No. 2 switch rail 14, and No. 1 connecting rail 15. No. 2 connecting rail 16, first to sixth nodes 1-6, and ore bin 8 and waste rock bin 9, wherein No. 1 connecting rail 15 and No. 2 connecting rail 16 are both X-shaped; Three nodes 1-3 form a row, the fourth to sixth nodes 4-6 form a row, and the first node 1 and the fourth node 4, the second node 2 and the fifth node 5, the third node 3 and the sixth node Nodes 6 correspond in pairs, and the fifth node 5 is located between the ore bin 8 and the waste rock bin 9;

[0013] The outer rail 11B of the No. 1 track and the outer rail 12B of the No. 2 track lead to the ore bin 8 and the waste rock bin 9 respectively, and the inner rail 11A of the No. 1 track and the inner rail 12A of the No. 2 track are at the second node 2 intersect; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com