Top thread maintaining and cleaning machine

A cleaning machine and jackscrew technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as lowering the quality of maintenance and cleaning jackscrews, incomplete cleaning, and wasting time, and achieve compactness Flexibility, reduced labor costs, and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following embodiments will further describe the present invention in conjunction with the accompanying drawings.

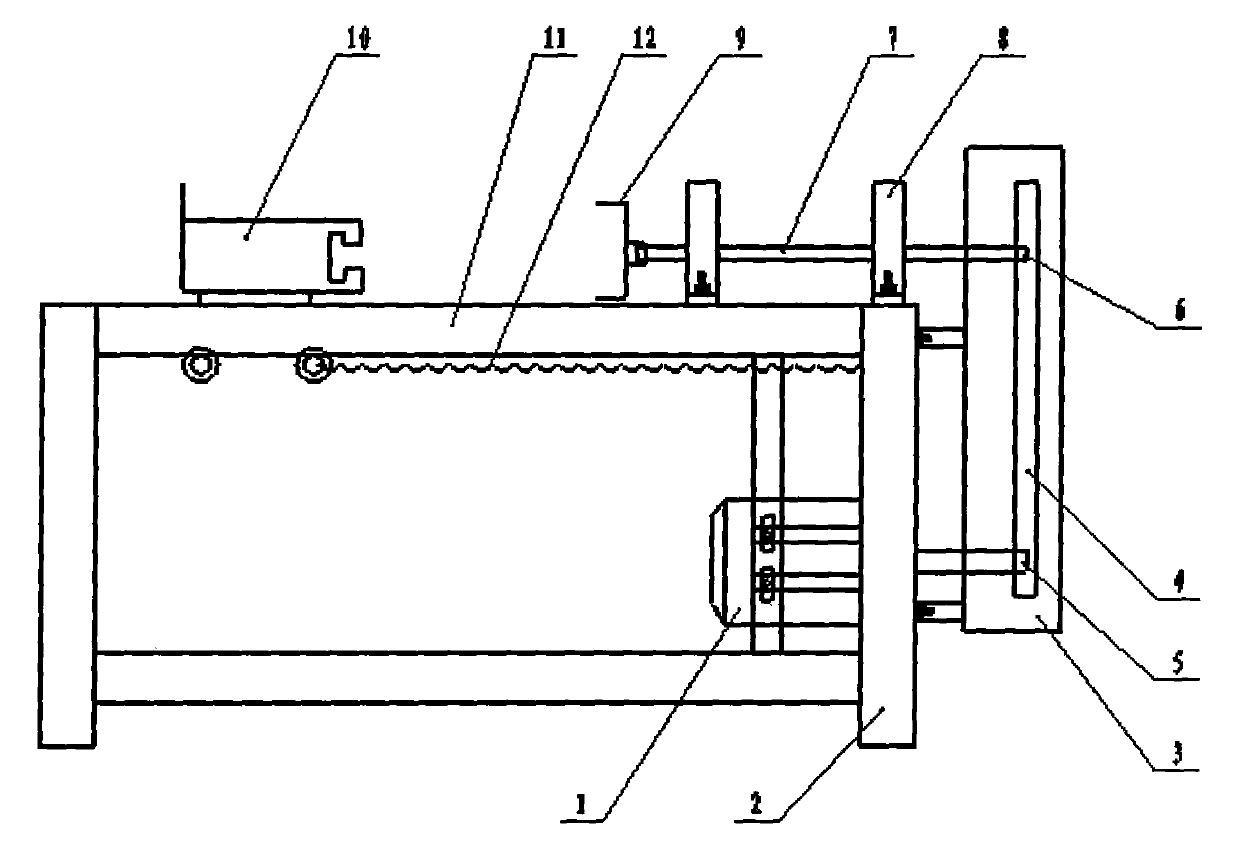

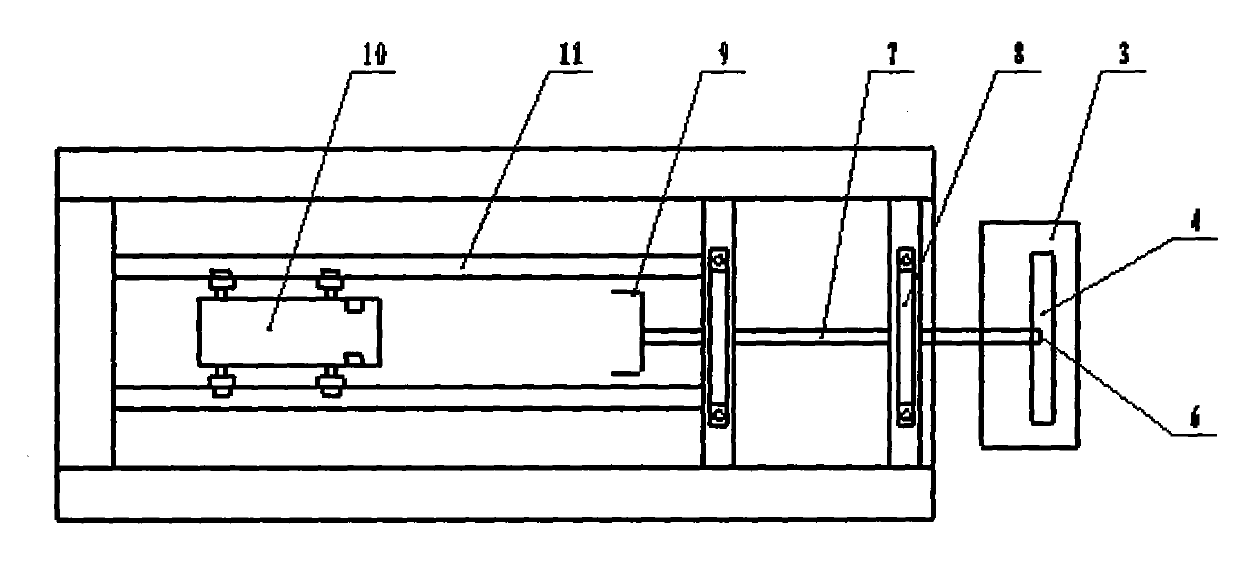

[0014] like figure 1 and figure 2 As shown, a jackscrew repair and cleaning machine includes a frame body 2, a motor 1, a jackscrew clamp 9 that fixes the jackscrew and rotates, and a sliding fixture 10 that fixes the nut to move back and forth, the jackscrew clamp 9 and the sliding clamp 9. The jig 10 is arranged on the same axis above the frame body 2 , and the motor 1 is connected with the top wire clamp 9 . The top wire clip 9 is connected with the driven wheel 6 through the transmission shaft 7 fixed on the bearing frame 8 , the output shaft of the motor 1 is fixed with the driving wheel 5 , and the driving wheel 5 is connected with the driven wheel 6 through the belt 4 . The motor 1 is located inside the frame body 2 , and the driving wheel 5 , driven wheel 6 and belt 4 are located on the other side outside the frame body 2 . Driving wheel 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com