Wire binding and stranding machine for electricians

A wire twisting machine and wire binding technology, which is applied in the field of wire binding and twisting machines for electricians, can solve problems such as knotted messy wires, winding, and affecting work efficiency, and achieves convenient handling and storage, convenient and simple use, and reduced manual operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

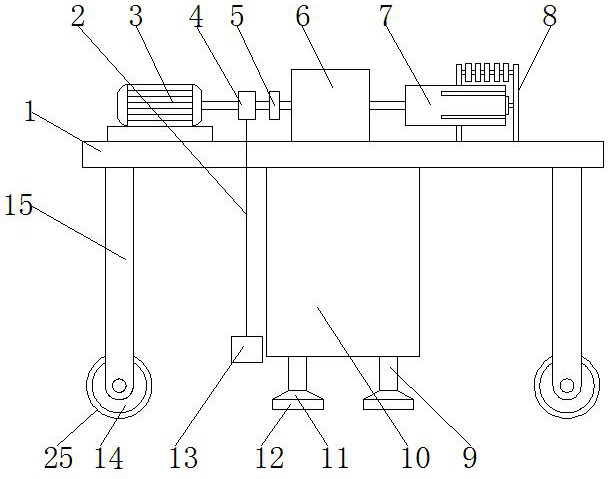

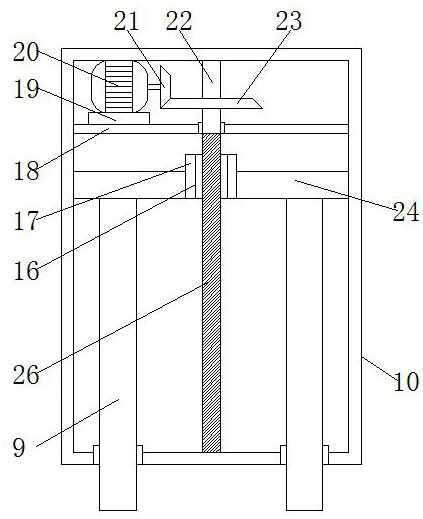

[0021] An embodiment of the present invention provides a wire binding and twisting machine for electricians, such as Figure 1-2 As shown, it includes the console 1, the left side of the top of the console 1 is fixedly connected with the first servo motor 3, the first servo motor 3 is turned on by turning on the first servo motor 3, and the first servo motor 3 drives the rotation after passing through the reducer The output shaft makes the wire winder 7 move, and one to four binding wires of pre-cut length are inserted into the wire winder 7 through the middle position of the pulley block on the incoming line positioning controller 8, and the wire winder 7 is driven by the rotation movement at the same time. One end of the binding wire is wound to form independent wire balls t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com