A pipe thread expansion joint interface and its equal-wall thread joint pipe and pipe fittings

A technology of threaded joints and connection interfaces, which is applied in the direction of pipes/pipe joints/pipe fittings, threaded connections, passing components, etc., to achieve the effect of solving excessive gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

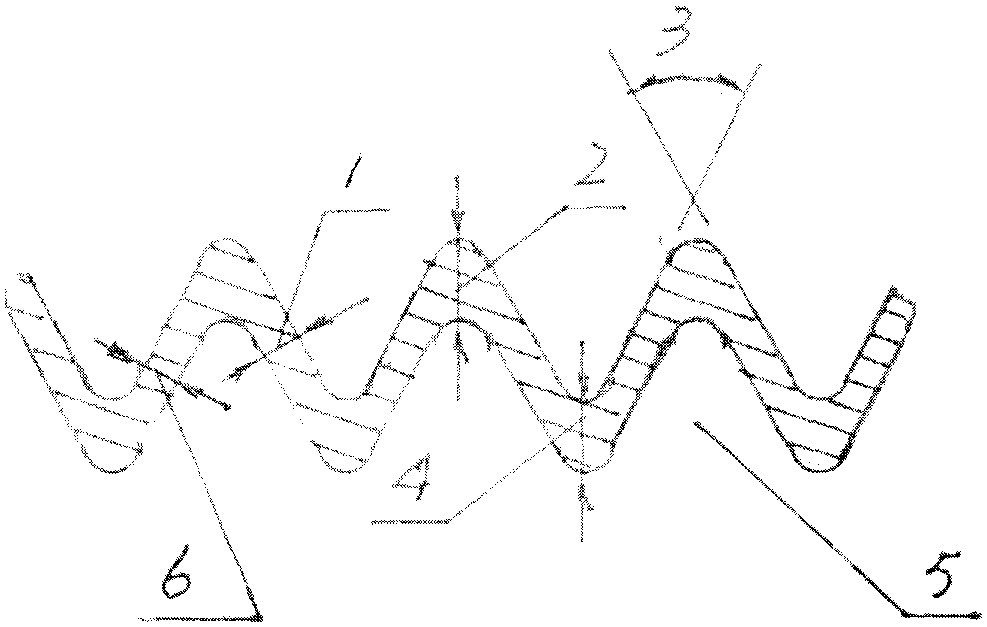

[0008] 1. Equal wall thread joint pipes and pipe fittings are connected to each other

[0009] Screw the equal-wall threaded joint pipe into the equal-wall threaded joint pipe fitting, and increase the torque of the rotary joint. When the conicity of the pipe fitting is slightly smaller than the conicity of the pipe, the tooth shape of the thread at the pipe end of the internal thread joint pipe fitting and the pipe According to the thread shape and tube shape of the screwed-in external threaded joint pipe, plastic deformation occurs, and the gap between the tooth shape and the tube shape of the internal and external threaded joint is eliminated, so that the interface forms a tightly sealed expansion joint seal ring; when the conicity of the pipe fittings is slightly larger than the conicity of the pipe, the thread profile and tube shape at the pipe end of the externally threaded joint pipe will be plastically deformed according to the thread profile and tube shape at the tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com