Device for detecting length of belt of engine of motor vehicle

A detection device and engine technology, applied in mechanical measurement devices, measurement devices, mechanical devices, etc., can solve the problems of cumbersome operation, low efficiency, poor belt length accuracy, etc., and achieve high detection efficiency, convenient operation, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

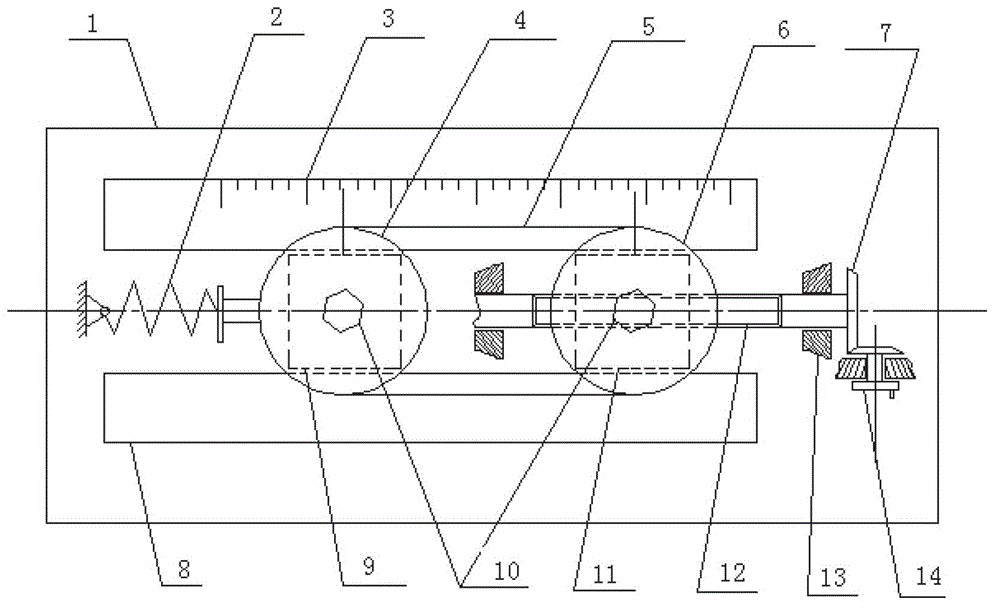

[0018] As shown in the figure, the technical solution provided by the present invention is a motor vehicle engine belt length detection device, including a platform 1, a spring scale 2, guide rails, pulleys, sliders and screw rods 12 are arranged on the platform 1, and the pulley The slide block is connected with the guide rail, and the slide block slides along the track guide rail between the two guide rails. The guide rails include a first guide rail 3 and a second guide rail 8 , the first guide rail 3 and the second guide rail 8 are arranged in parallel, and the first guide rail 3 is provided with a measuring scale marking line. Described pulley comprises first pulley 4 and second pulley 6, and described slide block comprises first slide block 9 and second slide block 11, and described first pulley 4 is fixed on the described first slide block 9 by bolt 10 , the first slider 9 is connected to the spring balance 2, and the spring balance 2 is fixed on the platform 1 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com