Balance force type electromagnetic relay clamping device with adjustable parameters

An electromagnetic relay and clamping device technology, which is applied to the measurement device shell, circuit breaker test and other directions, can solve the problems of unbalanced force type electromagnetic relay design parameter adjustment and other problems, and achieve the effect of quantitative research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

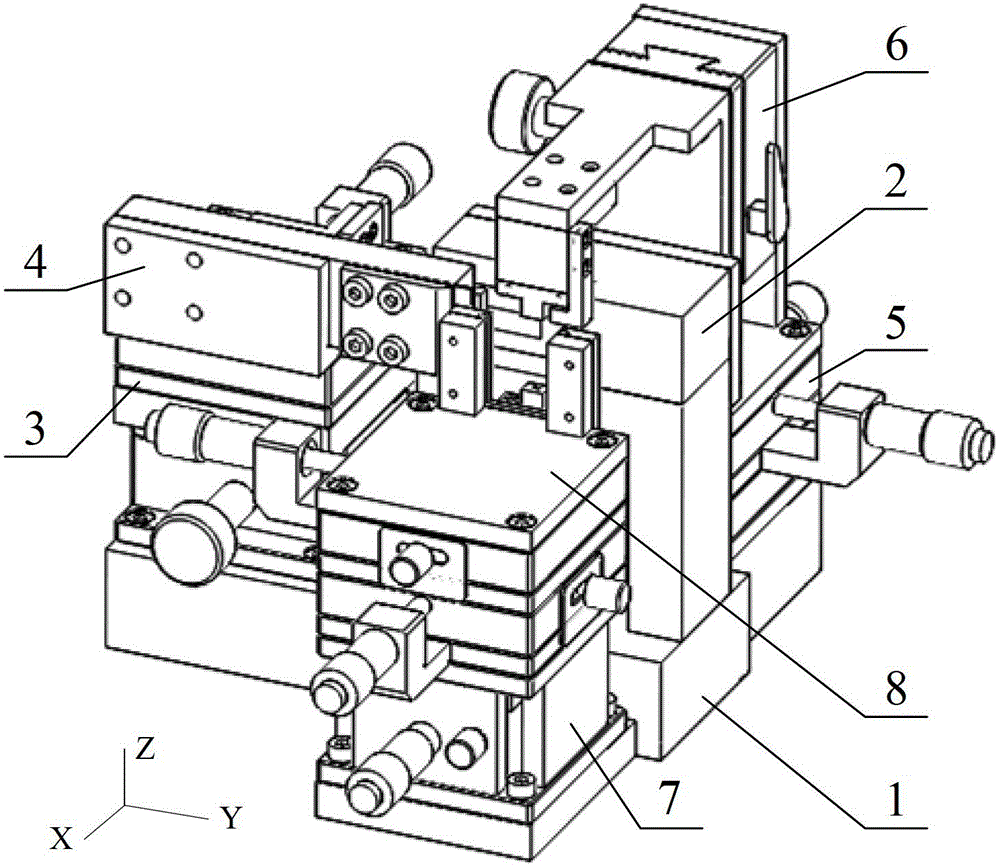

[0037] Specific implementation mode one, see figure 1 This embodiment will be described. The parameter-adjustable balance force electromagnetic relay clamping device described in this embodiment is composed of a base 1, an electromagnetic component positioning device 2, a short yoke adjusting device 3, a short yoke clamping device 4, an armature adjusting device 5, and an armature clamping device. Device 6, bottom plate adjustment device 7, bottom plate clamping device 8;

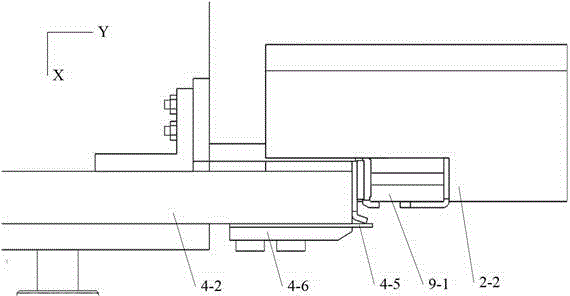

[0038] The electromagnetic component positioning device 2, the short yoke adjusting device 3, the armature adjusting device 5 and the bottom plate adjusting device 7 are fixed on the upper surface of the base 1; among them, the short yoke adjusting device 3 is used to support and fix the short yoke clip The clamping device 4 is used to adjust the position of the short yoke clamping device 4 in the X-Y two-dimensional plane; the short yoke clamping device 4 is used to cooperate with the electromagnetic comp...

specific Embodiment approach 2

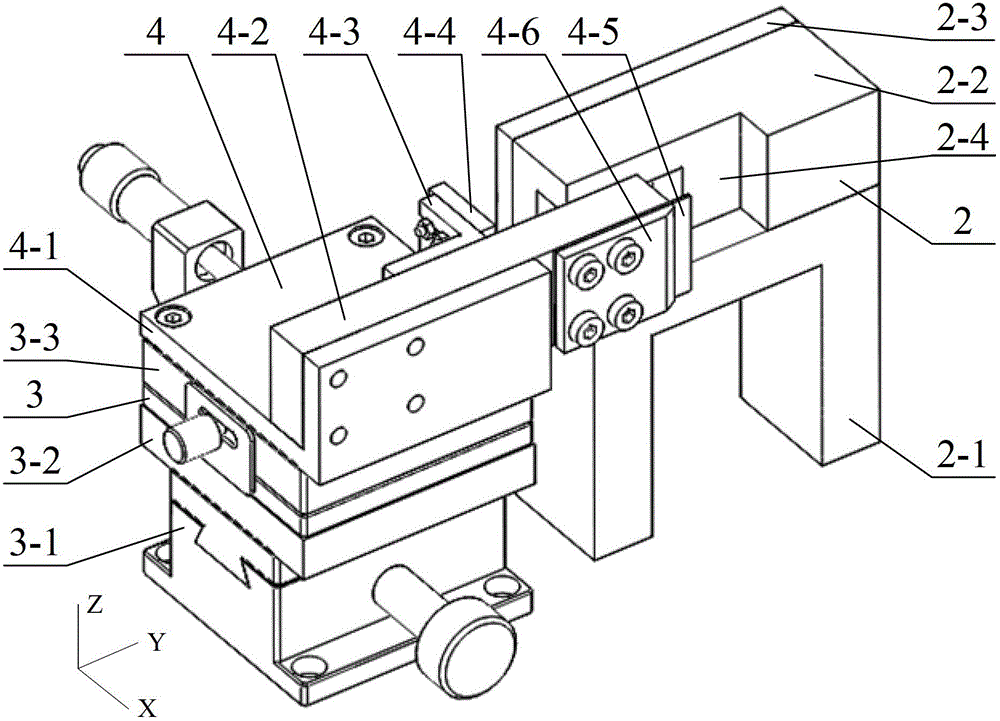

[0041] Specific implementation mode two, see figure 2 with 3 This embodiment will be described. This embodiment is a further limitation on the structure of the parameter-adjustable balance force electromagnetic relay clamping device described in the first specific embodiment. In this embodiment,

[0042] The electromagnetic component positioning device 2 is composed of a bracket 2-1, a positioning plate 2-2, and a side plate 2-3; -3 is fixedly installed on the upper end surface of the bracket 2-1, and the positioning plate 2-2 is provided with a positioning slot 2-4 for the electromagnetic component;

[0043] The short yoke adjustment device 3 is composed of a Y-axis adjustment slider 3-1, a connecting plate 3-2, and an X-axis adjustment slider 3-3; Fixed connection, the connecting plate 3-2 is fixed on the upper end surface of the Y-axis adjustment slider 3-1, and the X-axis adjustment slider 3-3 is fixed on the upper end surface of the connecting plate 3-2;

[0044] The...

specific Embodiment approach 3

[0046] Specific implementation mode three, see Figure 4 This embodiment will be described. This embodiment is a further limitation of the parameter-adjustable balance force electromagnetic relay clamping device described in the first or second specific embodiment. In this embodiment, the armature adjustment device 5 is composed of an X-axis adjustment slider 5-1, The Y-axis adjustment slide block 5-2 is composed of the X-axis adjustment slide block 5-1 for fixed connection with the upper end surface of the base 1, and the Y-axis adjustment slide block 5-2 is fixedly mounted on the X-axis adjustment slide block 5-1. End face; with such a design, the assembly position of the armature can be quantitatively adjusted in the Y-axis direction and the X-axis direction.

[0047] The structure of the armature clamping device 6 is further defined, and the armature clamping device 6 includes a lower base 6-1, a Z-axis adjustment slider 6-2, an upper base 6-3, a lower bracket 6-4, The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com