Laser-triggered gas switch

A gas switch and laser technology, applied in the field of power switches, can solve the problems of spark gap self-breakdown voltage and trigger breakdown voltage error, difficult to achieve dynamic sealing of spark gap, and difficult to accurately adjust the gap distance, so as to achieve self-breakdown Accurate voltage, convenient inflating and vacuuming operations, and convenient optical path calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

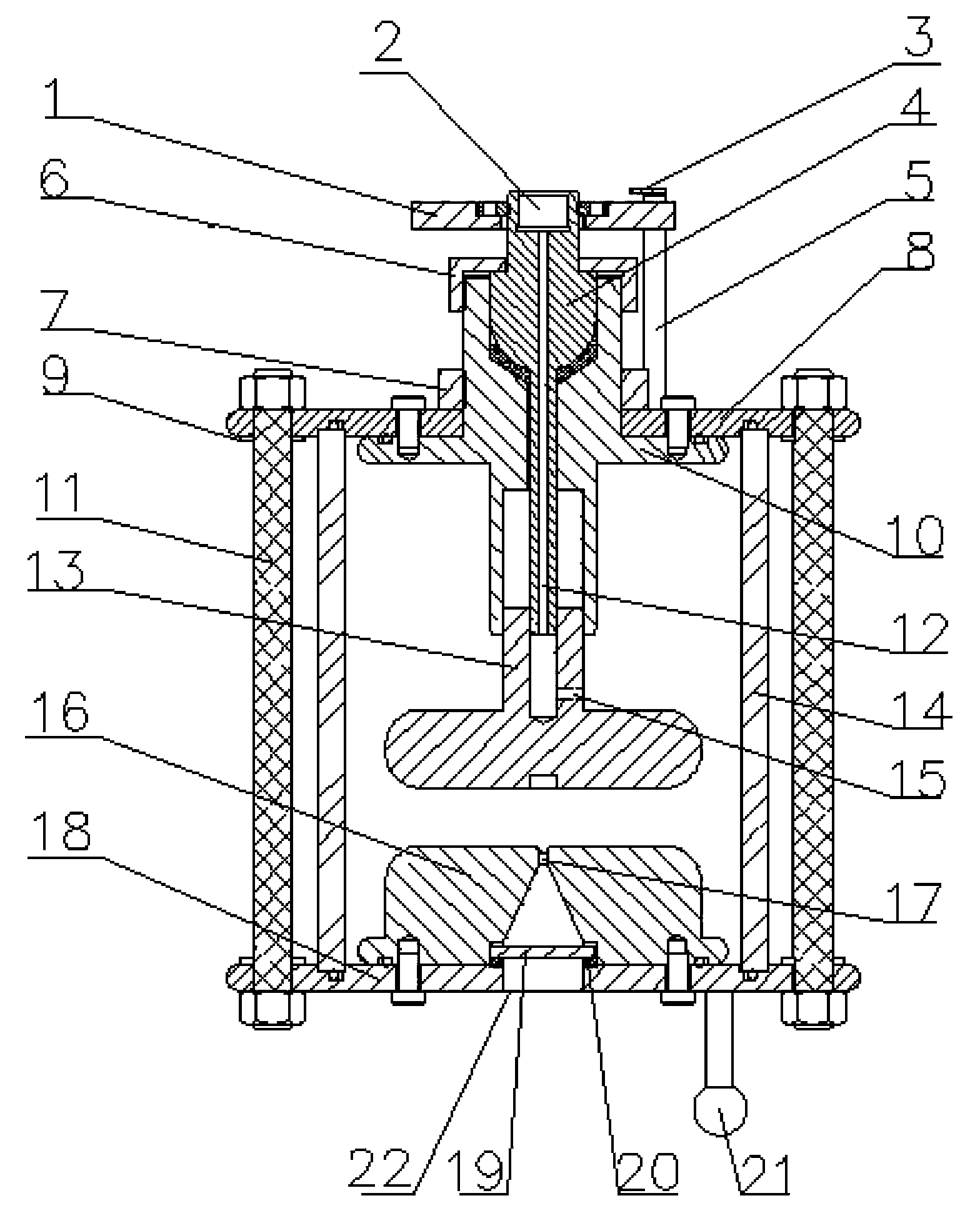

[0014] The laser trigger gas switch proposed by the present invention has a structure such as figure 1 As shown, it includes handwheel 1, reading pointer 3, pointer fixing rod 5, upper electrode seat 10, upper electrode 13, lower electrode 16, sealing sleeve 14, connecting rod 4, metal top plate 8, metal bottom plate 18, support rod 11 , Translucent glass plate 19 and terminal post 21. The metal top plate 8 and the metal bottom plate 18 are supported by the support rods 11, and the shielding rings 9 are respectively installed between the metal top plate 8, the metal bottom plate 18 and the support rods 11. The sealing sleeve 14 is placed between the metal top plate 8 and the metal bottom plate 18 , and a sealed cavity is formed in the sealing sleeve through the sealing rings at the upper and lower ends of the sealing sleeve 14 . The upper electrode holder 10 is fixed at the center of the metal top plate 8, the bottom of the upper electrode holder 10 stretches into the sealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com