A dual-channel single-gap plasma spraying device and its application

A technology of plasma and injection device, applied in the field of plasma injection device, can solve the problems of low injection gap energy, increase the difficulty of ignition gap, etc., and achieve the effects of long injection distance, simple structure and stable trigger performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

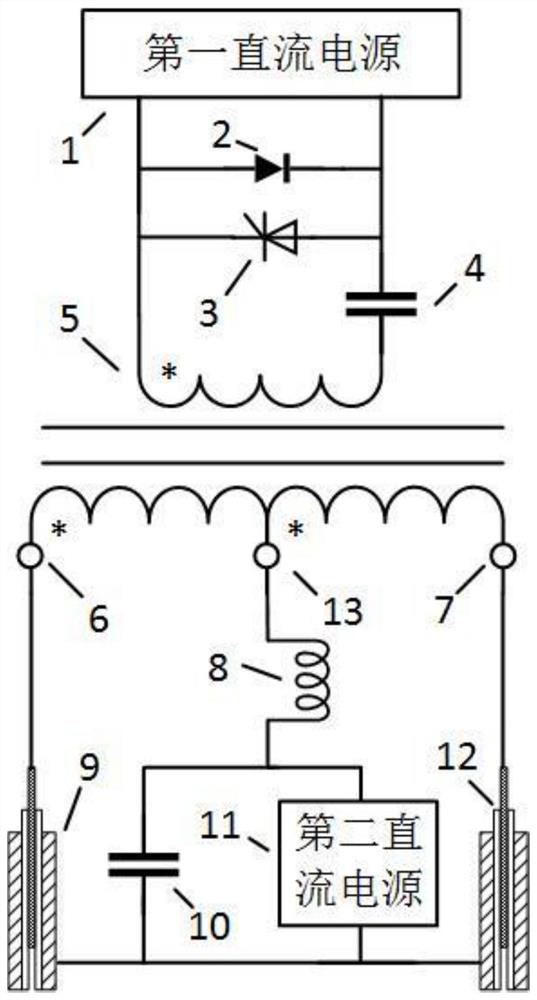

[0049] see figure 1 , a dual-channel single-gap plasma injection device, consisting of a first DC power supply, a freewheeling diode, a thyristor, a pulse capacitor, a pulse transformer, a second DC power supply, a main discharge capacitor, a protection inductor, and two plasma injectors .

[0050] Wherein, the pulse capacitor has a capacitance value of 1 μF, and is charged by the first DC power supply through the primary side of the pulse transformer. The discharge circuit is composed of the parallel circuit of the pulse capacitor, the thyristor and the freewheeling diode, and the primary side of the pulse transformer in series, and provides high-voltage trigger pulse output to the two plasma injectors.

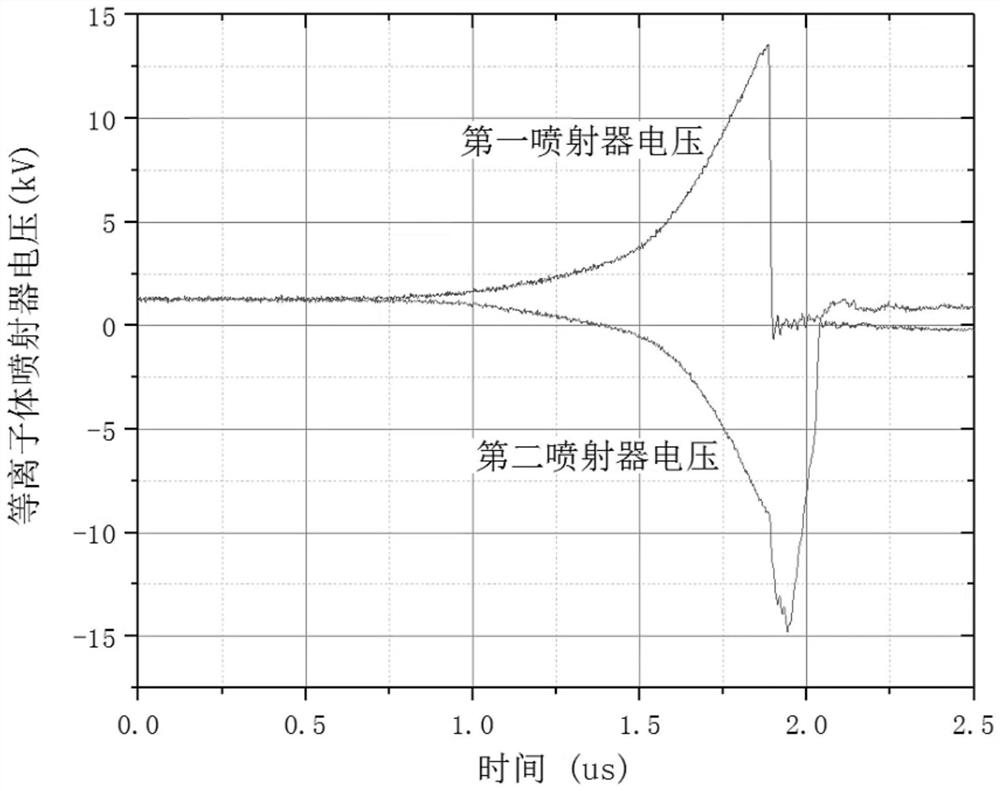

[0051] The main discharge capacitor is charged by the second DC power supply, its capacitance value is 20uF, and its charging voltage is 3kV. When the thyristor is turned on, the pulse capacitor is discharged through the thyristor and the primary side of the pulse transfor...

Embodiment 2

[0057] see figure 1 , a dual-channel single-gap plasma injection device, consisting of a first DC power supply, a freewheeling diode, a thyristor, a pulse capacitor, a pulse transformer, a second DC power supply, a main discharge capacitor, a protection inductor, and two plasma injectors .

[0058] Wherein, the pulse capacitor has a capacitance value of 4 μF, and is charged by the first DC power supply through the primary side of the pulse transformer. The discharge circuit is composed of the parallel circuit of the pulse capacitor, the thyristor and the freewheeling diode, and the primary side of the pulse transformer in series, and provides high-voltage trigger pulse output to the two plasma injectors.

[0059] The main discharge capacitor is charged by the second DC power supply, its capacitance value is 60uF, and the charging voltage is 2kV. When the thyristor is turned on, the pulse capacitor is discharged through the thyristor and the primary side of the pulse transfor...

Embodiment 3

[0065] see figure 1 , a dual-channel single-gap plasma injection device, consisting of a first DC power supply, a freewheeling diode, a thyristor, a pulse capacitor, a pulse transformer, a second DC power supply, a main discharge capacitor, a protection inductor, and two plasma injectors .

[0066]Wherein, the pulse capacitor has a capacitance value of 4 μF, and is charged by the first DC power supply through the primary side of the pulse transformer. The discharge circuit is composed of the parallel circuit of the pulse capacitor, the thyristor and the freewheeling diode, and the primary side of the pulse transformer in series, and provides high-voltage trigger pulse output to the two plasma injectors.

[0067] The main discharge capacitor is charged by the second DC power supply, its capacitance value is 120uF, and the charging voltage is 1kV. When the thyristor is turned on, the pulse capacitor is discharged through the thyristor and the primary side of the pulse transfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com