Segmented smoking article

A hot section, part technology, applied in the field of composition and construction of segmented smoking articles, which can solve the problem that smoking articles have not achieved widespread commercial success.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

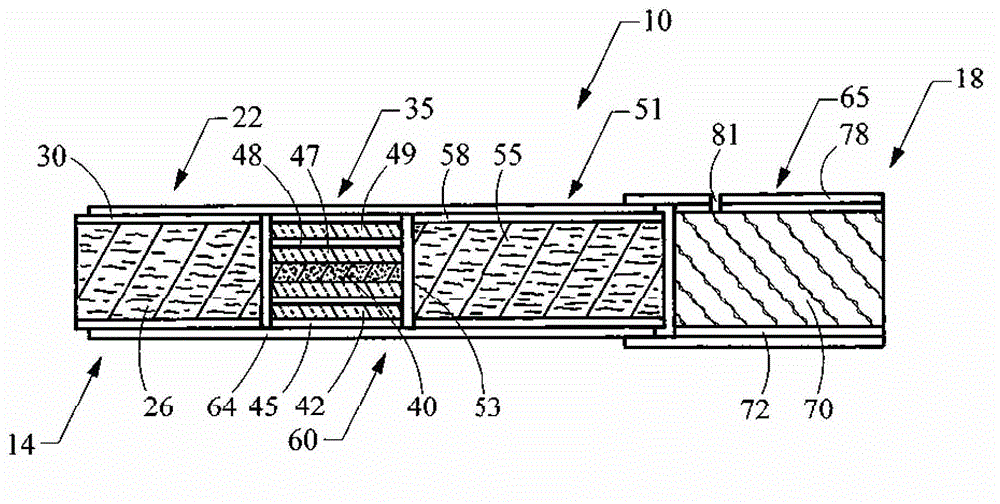

[0099] Example 1 - Extruded Substrates in Smoking Articles

[0100] In one embodiment, a smoking article of about 83-85 mm in length utilizes a heat source of about 12 mm in length, a substrate extruded according to the processes described herein and having a length of about 10 mm, a length of about 10 mm between the substrate and the filter element. 50mm hollow / empty tube and about 10mm long cellulose acetate filter. An exemplary extruded substrate was formed with ten outer grooves and a 0.032 inch central hole, and included the following components:

[0101] components

[0102] Can refer to Figure 7 The configuration of the illustrated cigarette 710 is used to understand the physical structure of the smoking article of Example 1.

example 2

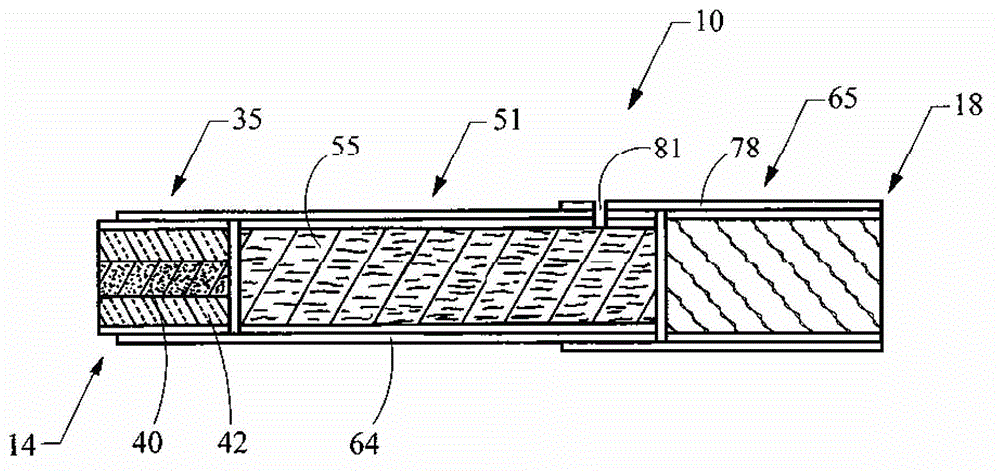

[0103] Example 2 - Extruded Substrates in Smoking Articles

[0104] In another embodiment, a smoking article is constructed using a heat source about 12 mm long, a substrate extruded according to the process described herein and about 50 mm in length, and a cellulose acetate filter about 10 mm long, between the substrate and filter There is a minimum interval between. An exemplary extruded substrate was formed with ten outer grooves and a 0.032 inch central hole, and included the following components:

[0105] components

[0106] Can refer to Figure 8 The construction of the illustrated cigarette 810 is used to understand the physical structure of the smoking article of Example 2.

example 3

[0107] Example 3 - Extruded Substrates in Smoking Articles

[0108] In another embodiment, a smoking article employs a heat source about 12 mm long, a substrate extruded according to the processes described herein and about 10 mm in length, a tobacco rod about 50 mm in length between the substrate and the filter, and about 10 mm in length. Made of cellulose acetate filter element. An exemplary extruded substrate was formed with ten outer grooves and a 0.032 inch central hole, and included the following components:

[0109] components

[0110] Can refer to Figure 9 The configuration of the illustrated cigarette 910 is used to understand the physical structure of the smoking article of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com